Circulating type modern high-efficiency agriculture production method

A production method and circulation-type technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve the problems of no water storage parts, low denitrification efficiency, and easy water seepage, etc., to increase speed and increase Purification range, effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

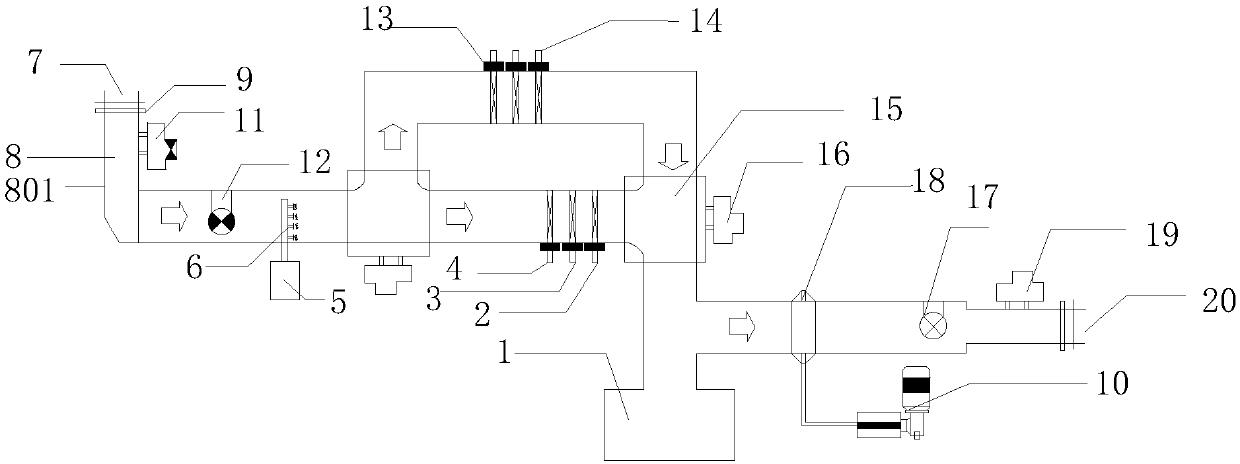

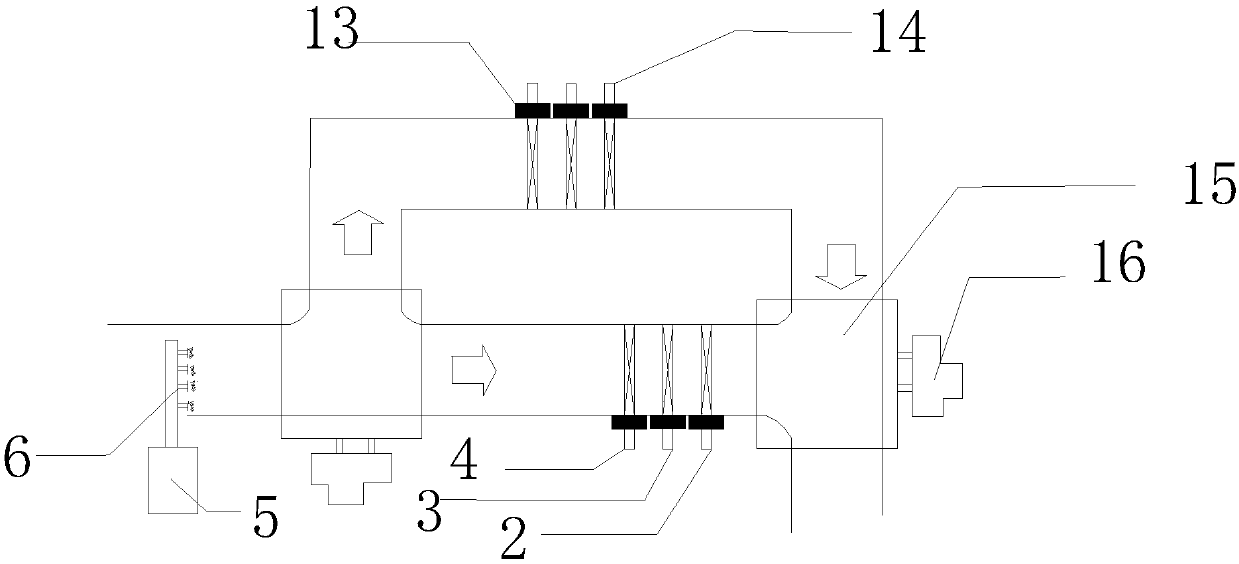

[0015] A recycling-type modern high-efficiency agricultural production method is characterized in that its structure includes a reservoir 1, a first plate-type catalytic layer 2, a second plate-type catalytic layer 3, a third plate-type catalytic layer 4, an ammonia gas storage tank 5, Ammonia injector 6, air inlet 7, cylinder 8, anti-corrosion heat insulation layer 801, expansion joint 9, small motor 10, air inlet valve 11, first smoke detector 12, sealing ring 13, stainless steel grid 14, Three-way converter 15, three-way valve 16, second smoke detector 17, dust remover 18, air outlet valve 19, air outlet 20; the expansion joint 9 is connected to the air inlet 7, and the air inlet valve 11 Fixed at the air inlet 7, the first flue gas detector 12 is connected with the cylinder body 8 and fixed at the air inlet 7, the ammonia storage tank 5 is connected with the ammonia injector 6, the three-way The converter 15 is connected with the three-way valve 16, the sealing ring 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com