System for treating desulfurization wastewater by evaporation with high-temperature flue gas

A technology for desulfurization wastewater and treatment system, which is applied in gaseous effluent wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc. The overall structure is simple, the operation control is convenient, and the effect of improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

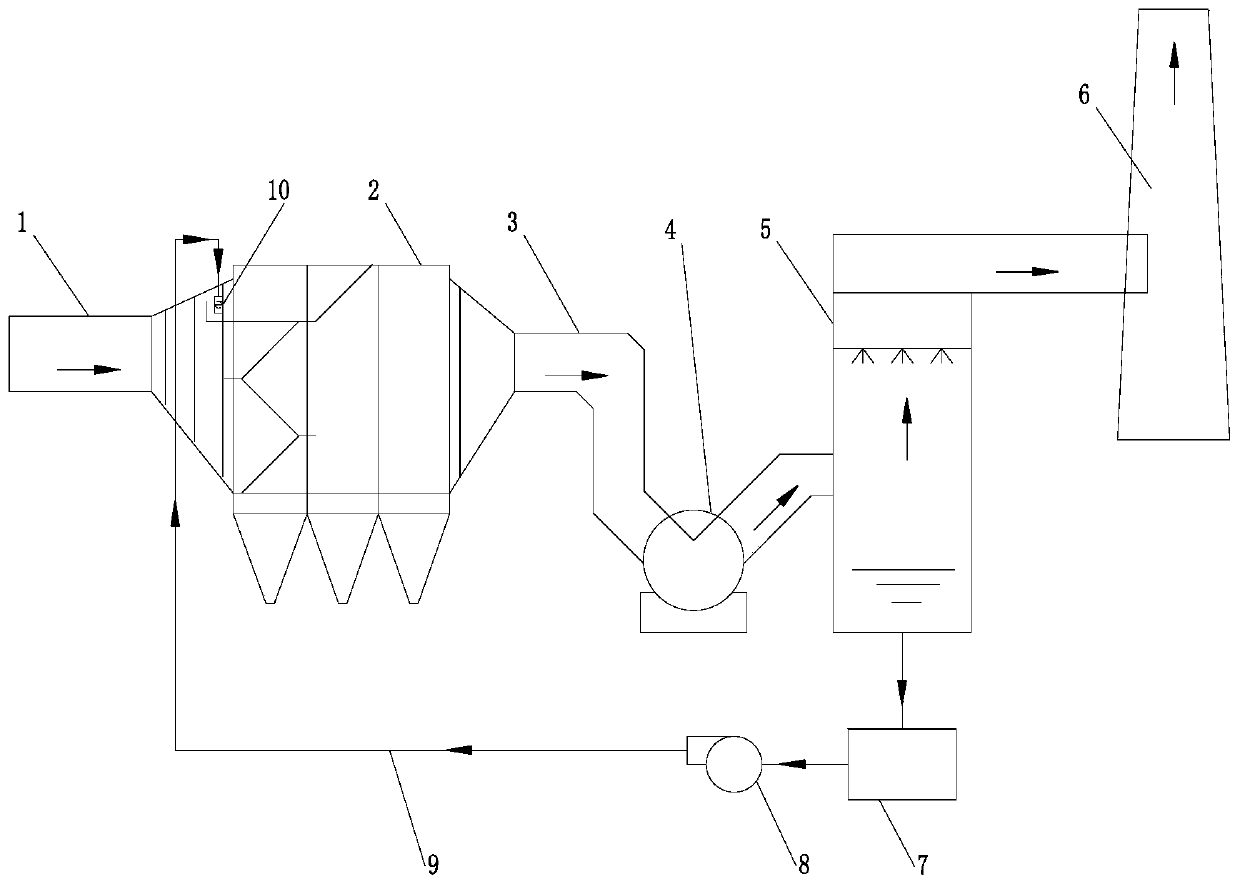

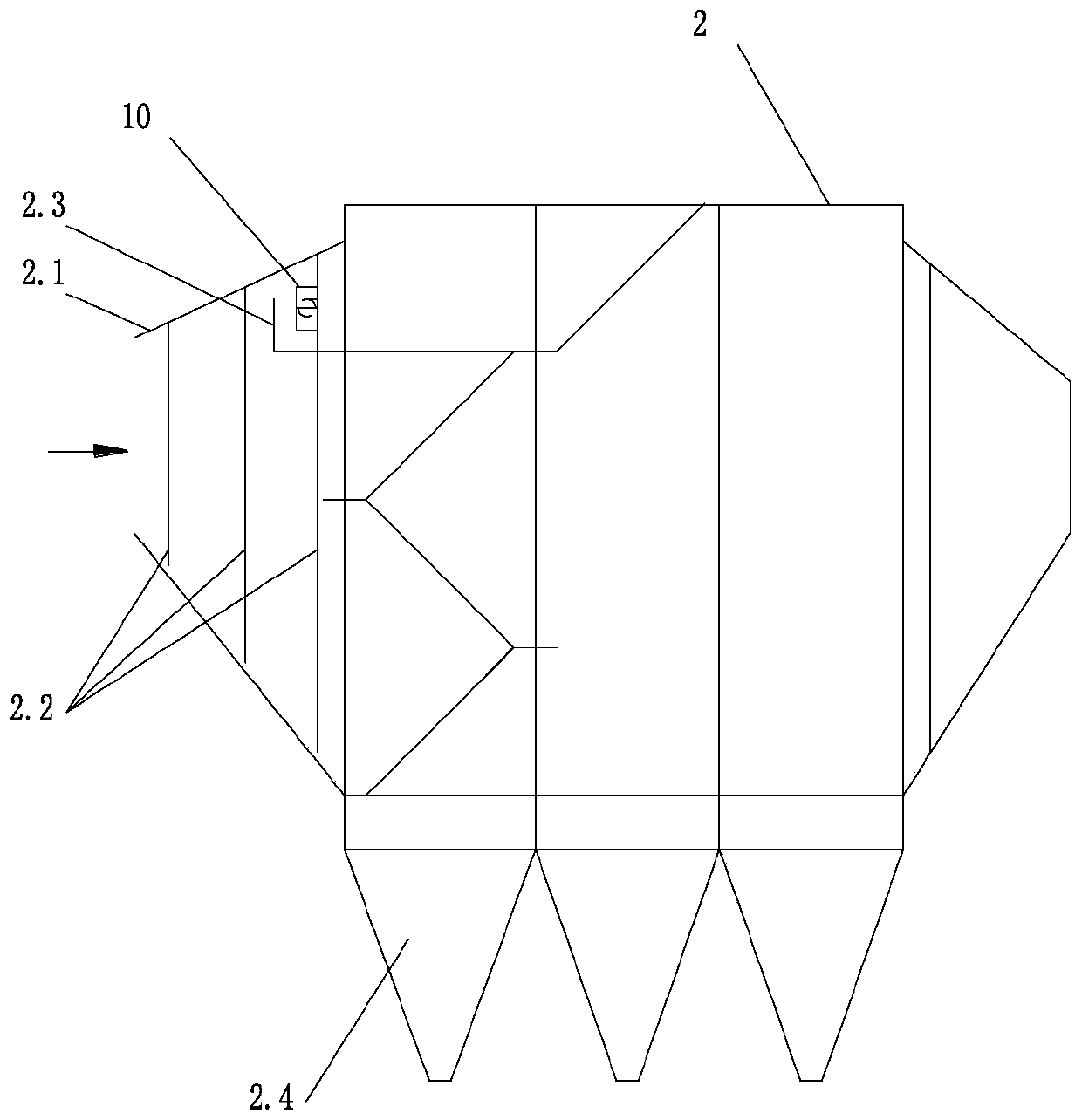

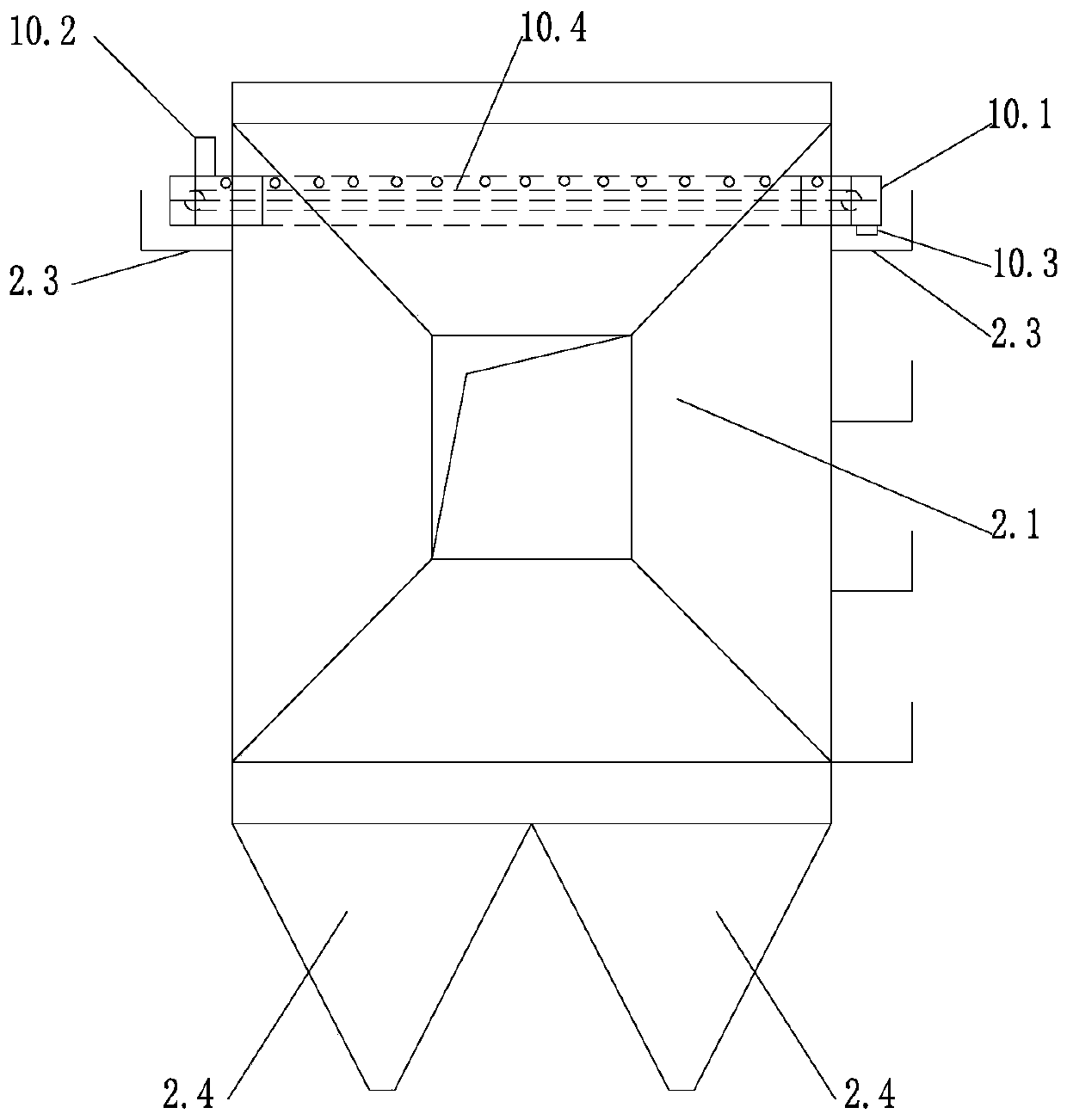

[0027] Embodiment one: if Figure 1-4 The shown a kind of high-temperature flue gas evaporative desulfurization wastewater treatment system comprises the original flue 1 connected in sequence, the electrostatic precipitator 2, the flue 3 after dust removal, the induced draft fan 4, the desulfurization tower 5 and the chimney 6, and the desulfurization tower 5 The bottom is connected with waste water tank 7. Wherein, the electrostatic precipitator 2 includes an inlet horn 2.1, an airflow distribution plate 2.2, an external maintenance platform 2.3 and an ash hopper 2.4, and an evaporation device 10 is horizontally arranged in the inlet horn 2.1.

[0028] The evaporating device 10 comprises a shell 10.1 with an open top. The two ends of the shell 10.1 along its length direction are respectively provided with a feed port 10.2 and a discharge port 10.3. There is a conveying device 10.4 for conveying desulfurization wastewater. Described waste water tank 7 links to each other wit...

Embodiment 2

[0042] Embodiment 2: substantially the same as Embodiment 1, the difference is that the level of the conveyor belt 10.4.1 at the end of the feed port 10.2 is higher than the level of the conveyor belt 10.4.1 at the end of the discharge port 10.3. After the desulfurization wastewater enters the upper surface of the conveyor belt 10.4.1, it can automatically slide down from the end of the conveyor belt 10.4.1 located at the feed port 10.2 to the end of the conveyor belt 10.4.1 located at the discharge port 10.3 under the action of gravity, thereby reducing Conveyor belt 10.4.1 is located at the leakage of feeding port 10.2 one end.

Embodiment 3

[0043] Embodiment three: substantially the same as embodiment one, the difference is that the level of the middle part of the conveyor belt 10.4.1 is lower than the level of both ends. After the desulfurization wastewater is on the upper surface of the conveyor belt 10.4.1, it moves to the middle of the conveyor belt 10.4.1 and then deposits in the depression, so as to increase the contact time with the high-temperature flue gas and evaporate more fully.

[0044] Compared with the prior art, the present invention has the advantages of:

[0045] 1. The flue gas temperature at the inlet of the electrostatic precipitator in coal-fired power plants is generally 120-160°C, which is significantly higher than the boiling point of water under normal conditions. Moreover, compared with the flue gas volume of the unit, the amount of waste water produced by desulfurization is small, and the water can be completely evaporated after being sent into the flue gas.

[0046] 2. During the eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com