Soybean processing pretreatment method

A technology of pretreatment and pretreatment device, which is applied in the field of soybean processing and pretreatment, can solve the problems of difficult processing of soybean iron beans, incomplete screening, uneven swelling of soybeans due to water absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

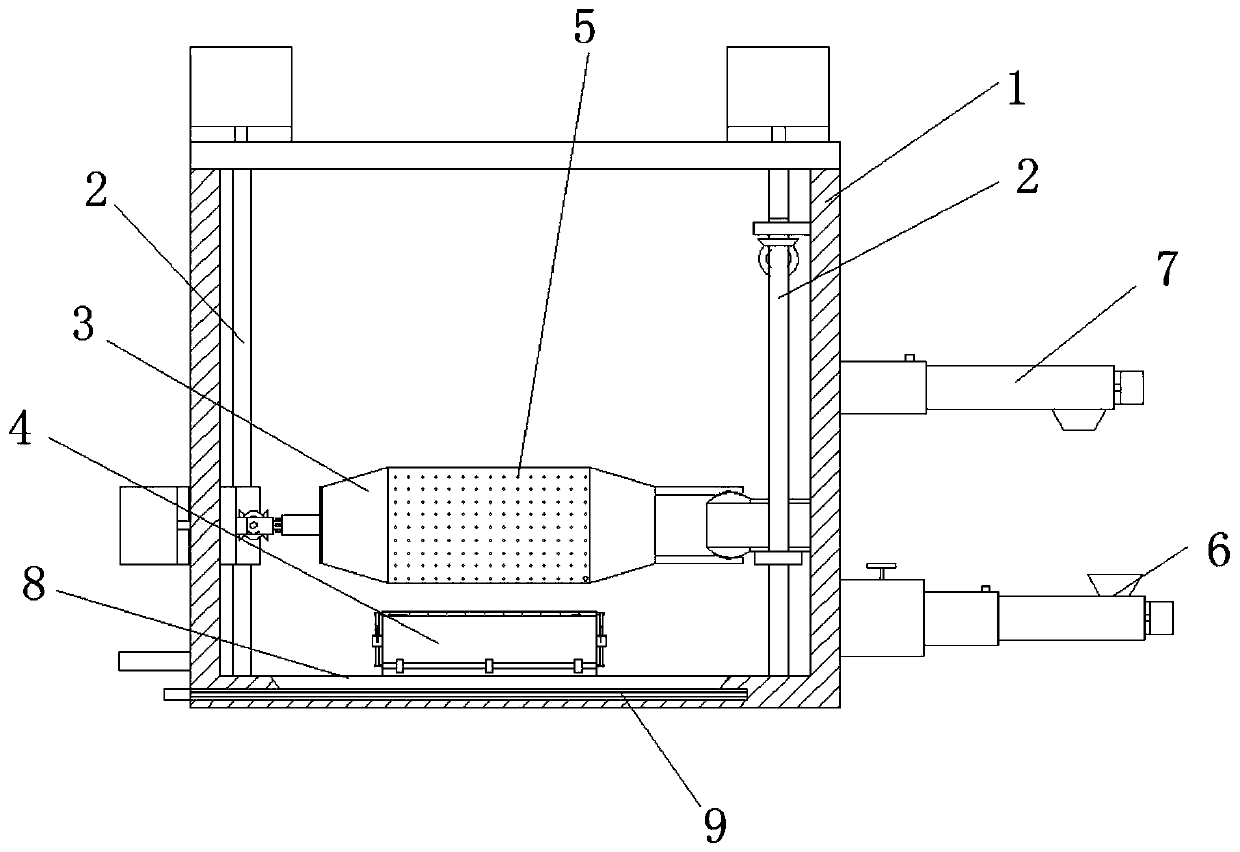

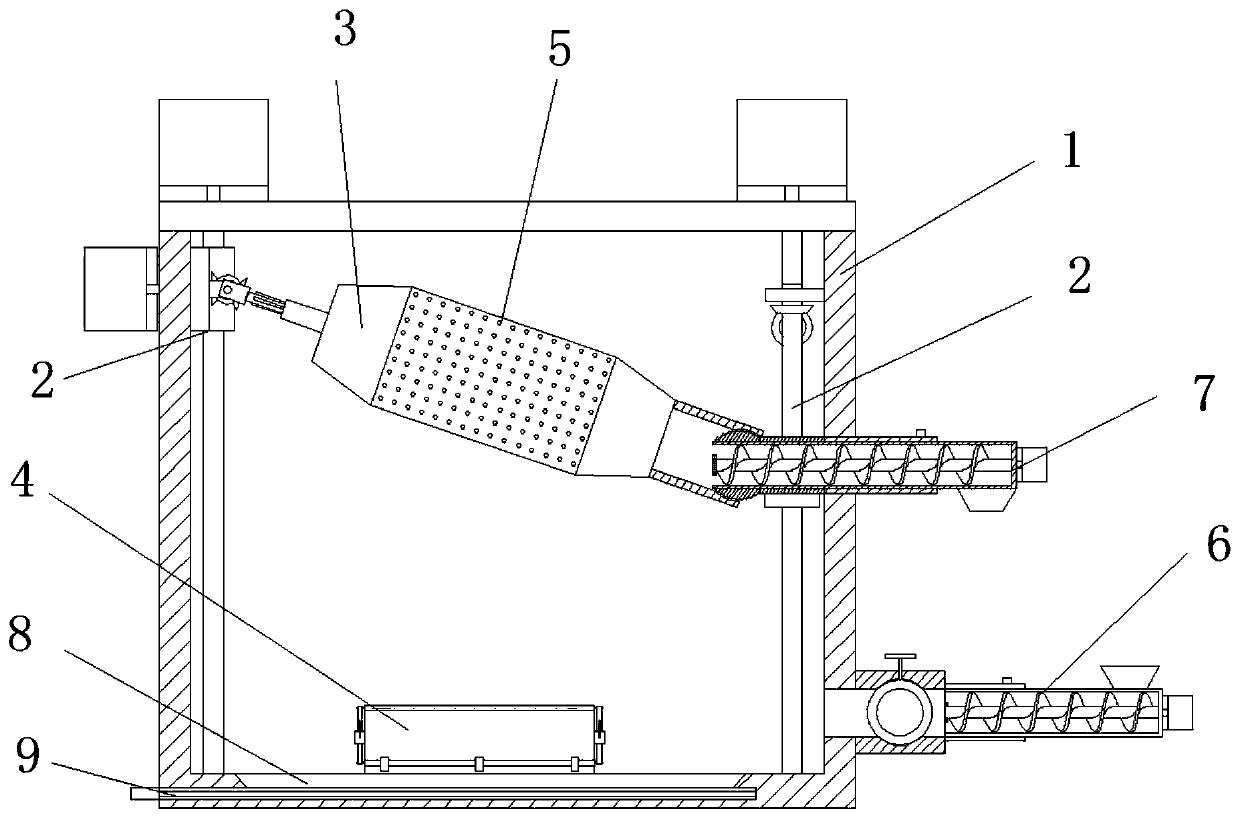

[0053] This embodiment is an embodiment of a soybean processing pretreatment device.

[0054] like figure 1 , 2 , 3, 4, and 5, a soybean processing pretreatment device disclosed in this embodiment includes a sealing box 1, a position adjusting device 2, a material holding device 3, a blocking member 4, a feeding device 6, and a discharging device 7 and sealing plate 9; the sealing box 1 is provided with a positioning device 2, a material holding device 3 and a blocking member 4, the blocking member 4 is arranged at the bottom of the sealing box 1, and the material holding device 3 is located at the bottom of the sealing box 1. Just above the blocking member 4, the two ends of the material holding device 3 are connected to the position adjusting device 2, and the material holding device 3 is provided with a screen hole 5, and the position adjusting device 2 can control the distance between the material holding device 3 and the sealing box 1. The height of the bottom is agains...

specific Embodiment approach 2

[0061] This embodiment is an embodiment of a soybean processing pretreatment device.

[0062] A soybean processing pretreatment method disclosed in the present embodiment comprises the following steps:

[0063] Step a, primary sieving, the soybeans are subjected to a vibrating cleaning sieve and preliminarily sieved. The diameter of the circular sieve hole is Φ4.0-4.5mm, and a wire sieve surface with a length of 4.0-4.5mm on each side of the sieve hole can also be used, Screen out impurities with a particle size larger than the sieve hole;

[0064]Step b, feeding, controlling the position adjustment device 2, adjusting the level of the material holding device 3 and moving downward, moving to abut against the blocking member 4, and at the same time, the feeding and discharging pipes 3-6 are in contact with the feeding device 6, counterclockwise. Rotate the manual rotary rod 6-1-3 by 90°, so that the through hole of the ball valve 6-1-2 corresponds to the inner wall of the firs...

specific Embodiment approach 3

[0072] This embodiment is an embodiment of a position adjusting device. It should be noted that the position adjustment device in this embodiment can be implemented independently, that is, as a part of a soybean processing pretreatment device, or can be used for the soybean processing pretreatment device described in the first embodiment. further limited.

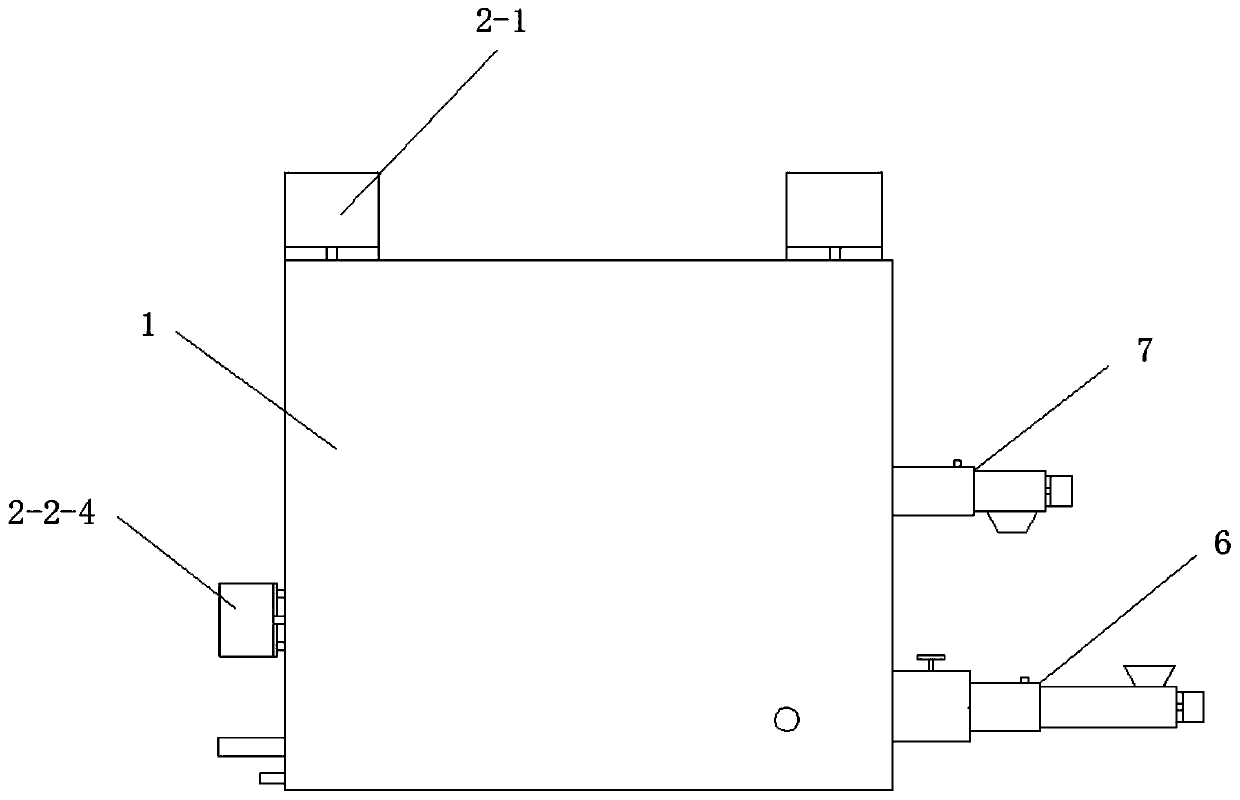

[0073] combine Figure 4-9 As shown in the figure, a position adjusting device for a soybean processing pretreatment device disclosed in this embodiment includes a position adjusting motor 2-1, a first position adjusting member 2-2 and a second position adjusting member 2-3; The motors 2-1 are respectively arranged on the left and right ends of the upper surface of the cover plate of the sealing box 1. The position adjustment motor 2-1 at the left end is connected with the first position adjustment member 2-2, and the position adjustment motor 2-1 at the right end is connected with the second adjustment member. Bit member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com