Full-automatic baking line and operating method thereof

A baking method and fully automatic technology, applied in baking, food science, loading/unloading of ovens, etc., can solve the problems of limited one-time baking volume and inability to meet automated food production, and achieve a large one-time baking volume, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

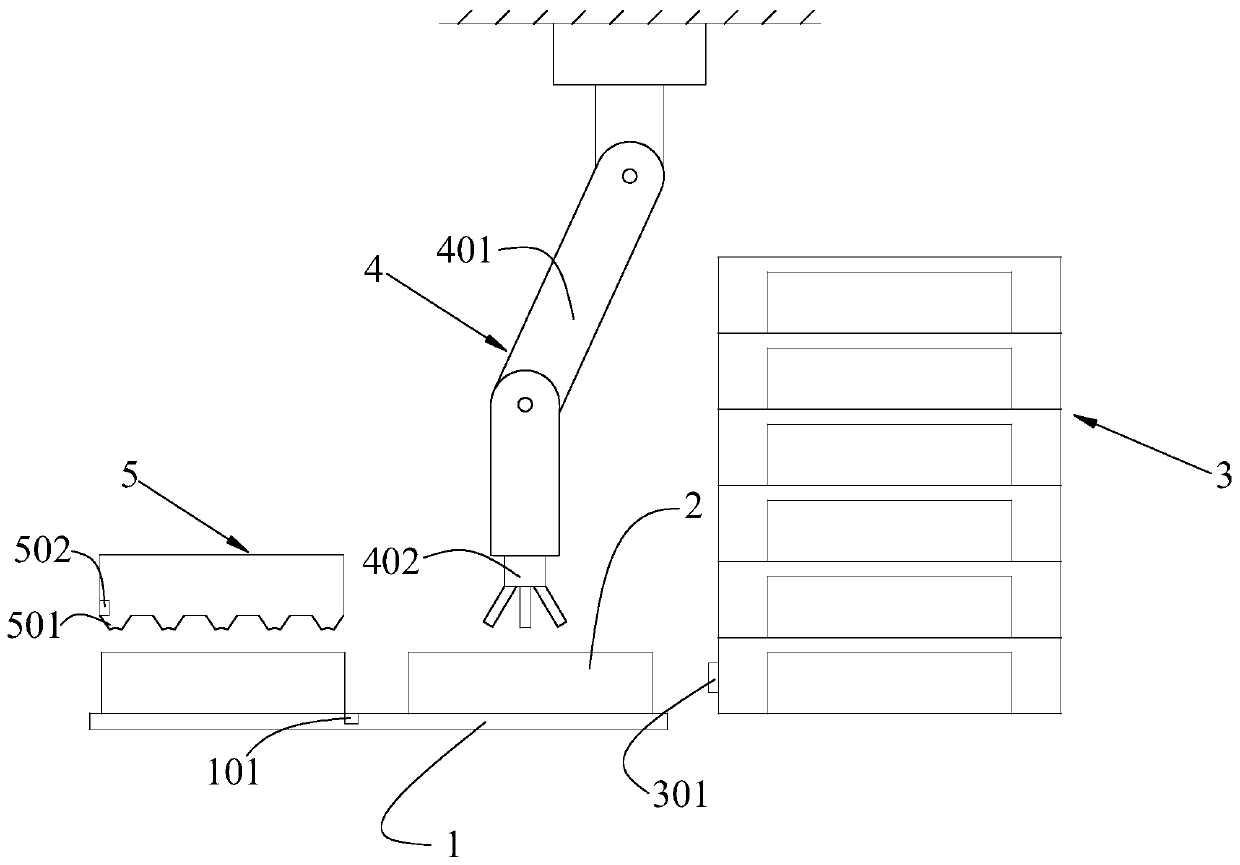

[0038] figure 1 is a schematic diagram of the fully automatic baking production line of the present invention;

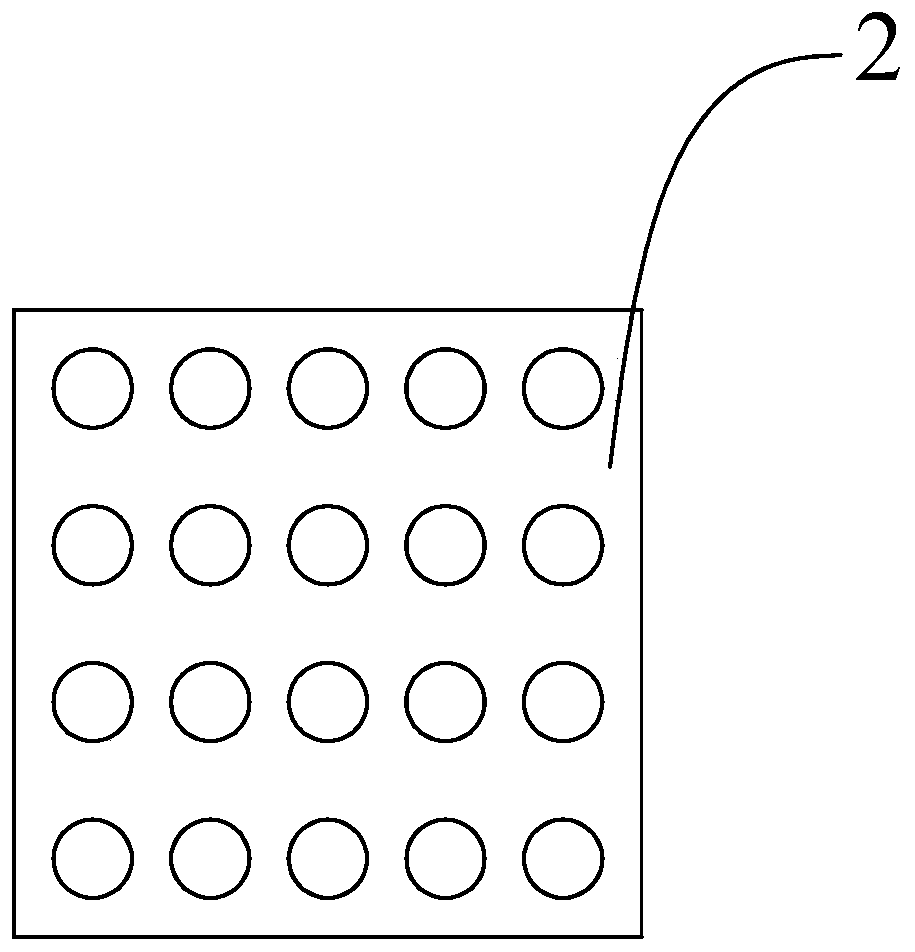

[0039] figure 2 It is a top view of the cake mold in the fully automatic baking production line of the present invention;

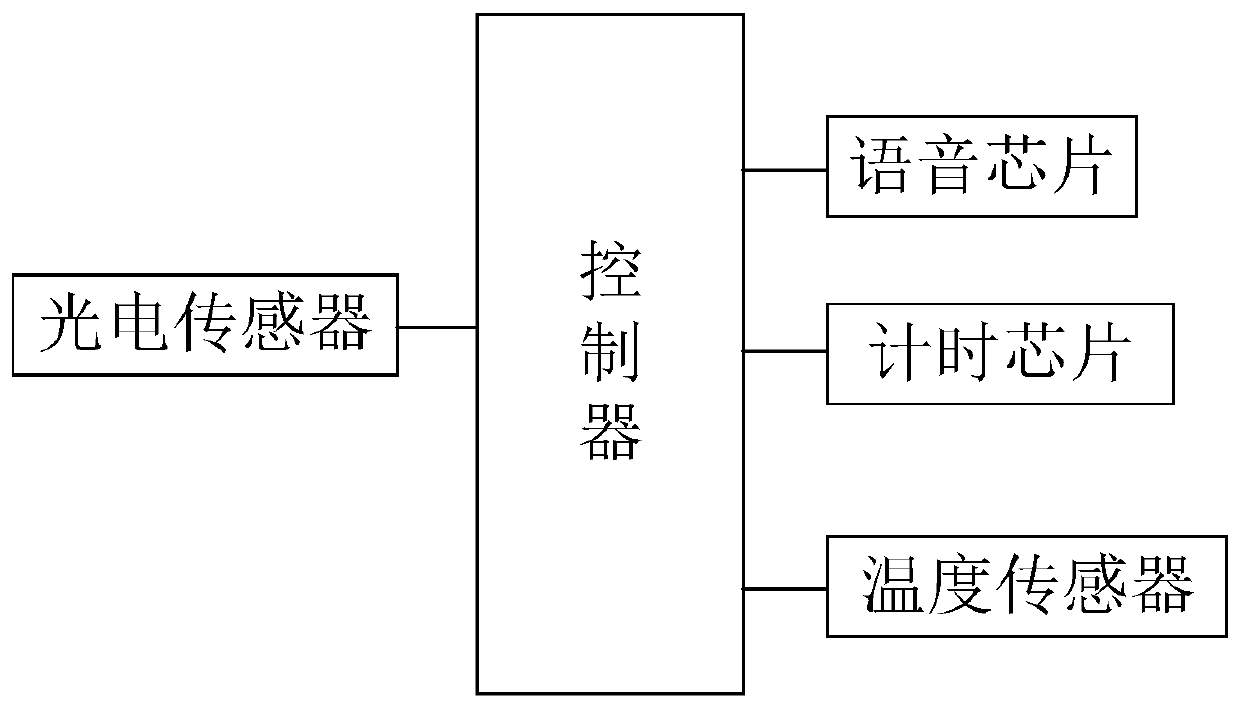

[0040] image 3 It is a functional block diagram of the fully automatic baking production line of the present invention.

[0041] Such as Figures 1 to 3 As shown, the present embodiment provides a fully automatic baking production line, including: a controller, an oven 3, a conveyor belt 1 positioned at the inlet of the oven 3, and a manipulator 4 suspended; wherein the conveyor belt 1 and the manipulator 4 are controlled by the controller. Control; the position of the oven 3 corresponding to the conveyor belt 1 is provided with a first photoelectric sensor 301, and the first photoelectric sensor 301 is electrically connected to the controller; a number of cake molds 2 filled with cake liquid are transported sequentially through the conve...

Embodiment 2

[0052] On the basis of Embodiment 1, this embodiment provides an automatic baking method, including: the manipulator 4 grabs the cake mold 2 and puts it into the oven 3 for baking.

[0053]In this embodiment, the automatic baking method includes: a controller, an oven 3, a conveyor belt 1 located at the inlet of the oven 3, and a manipulator 4 suspended; wherein the conveyor belt 1 and the manipulator 4 are both controlled by the controller; The position of the oven 3 corresponding to the conveyor belt 1 is provided with a first photoelectric sensor 301, and the first photoelectric sensor 301 is electrically connected to the controller; several cake molds 2 filled with cake liquid are transported sequentially through the conveyor belt 1, and the first photoelectric sensor 301 is triggered when it is close to the oven 3. sensor 301, the controller controls the conveyor belt 1 to stop conveying, and at the same time controls the manipulator 4 to grab the cake mold 2 and put it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com