Device and method for the detection of wear on a sliding contact and brushgear system

A technology of sliding wires and sliding contacts, which is applied in the direction of electric components, electric vehicles, power lines, etc., and can solve the problem of moving parts that can no longer be triggered correctly, pulse triggers and collectors produce mechanical contact, and pulse triggers Affected by corrosion and other problems, to achieve the effect of reliable wear level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

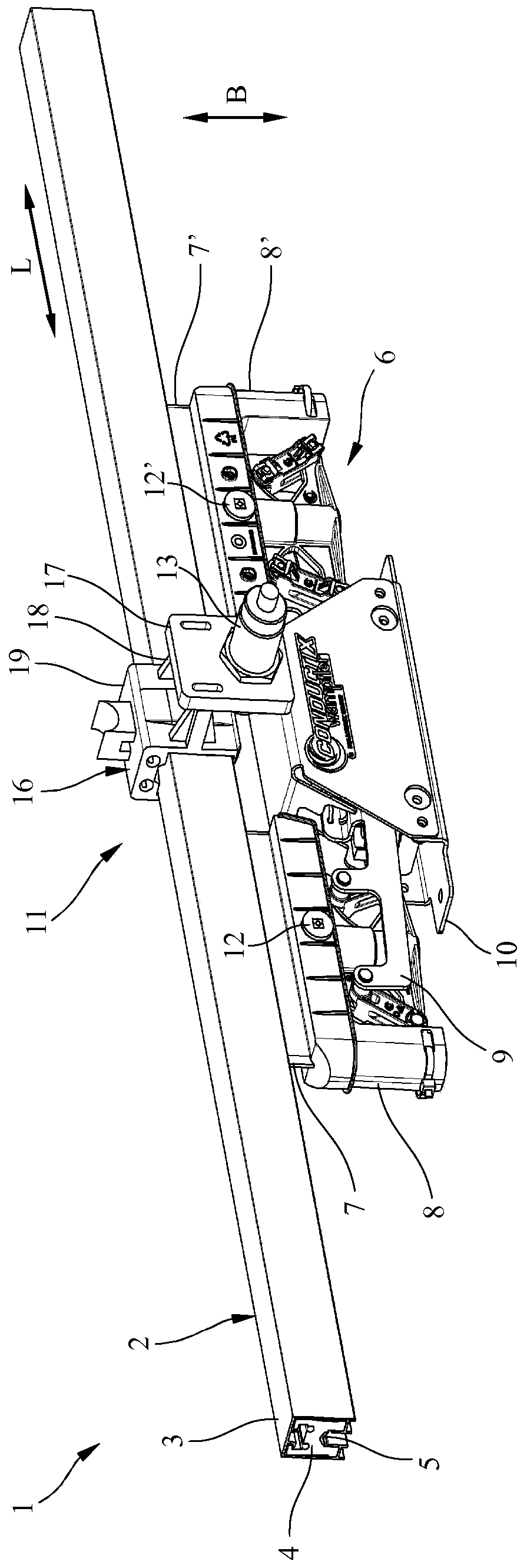

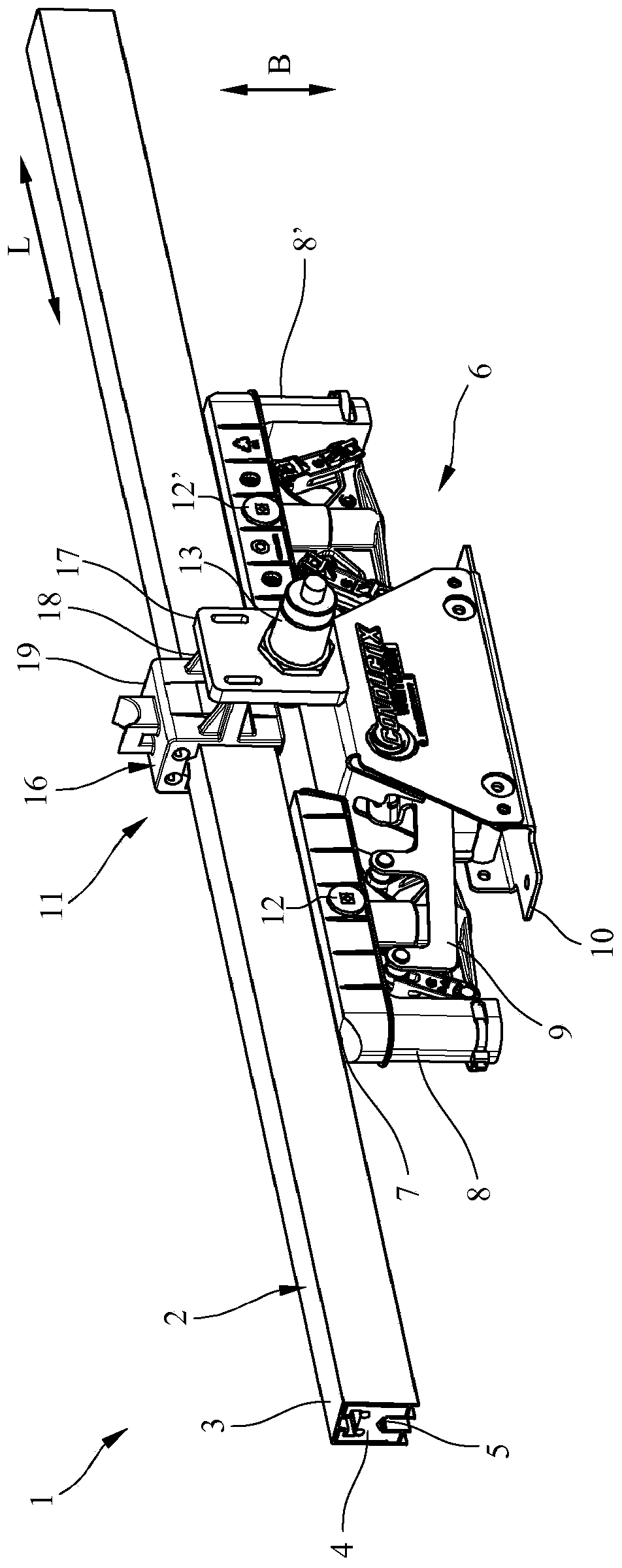

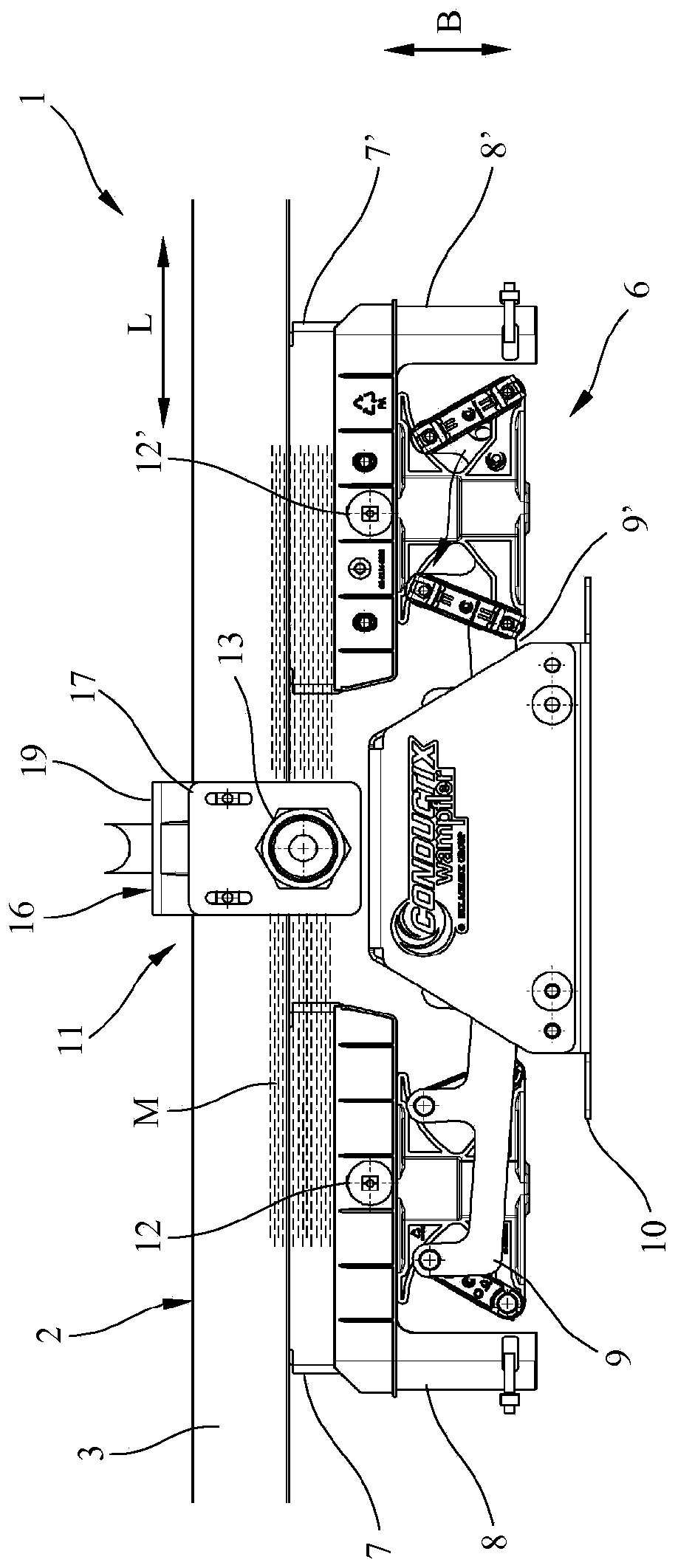

[0029] figure 1 A schematic three-dimensional view of a section of a conductor line system 1 according to the invention is shown, which has a conductor conductor 2 extending in the longitudinal direction L. FIG.

[0030] The conductor conductor 2 has an elongated insulating profile 3 which surrounds an elongated, electrically conductive phase conductor profile 4 with an embedded electrically conductive, elongated sliding contact surface 5 which preferably Made of aluminum or steel.

[0031] Current collectors 6 of electrical consumers, not shown in the figure, can be moved along the conductor lines 2 . In this case, the current collector 6 is used to supply electrical consumers movable along the trolley line and electrical devices mounted thereon with different electric running gears and lifting gears, such as electric overhead conveyors or container cranes.

[0032] The current collector 6 has a sliding contact 7 designed as a carbon brush, which during operation moves agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com