Fuel cell cooling system adopting organic working medium

A fuel cell and cooling system technology, which is applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of unfavorable fast start-up and long time required for the system, achieve less system weight and increase net output The effect of power and rapid temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

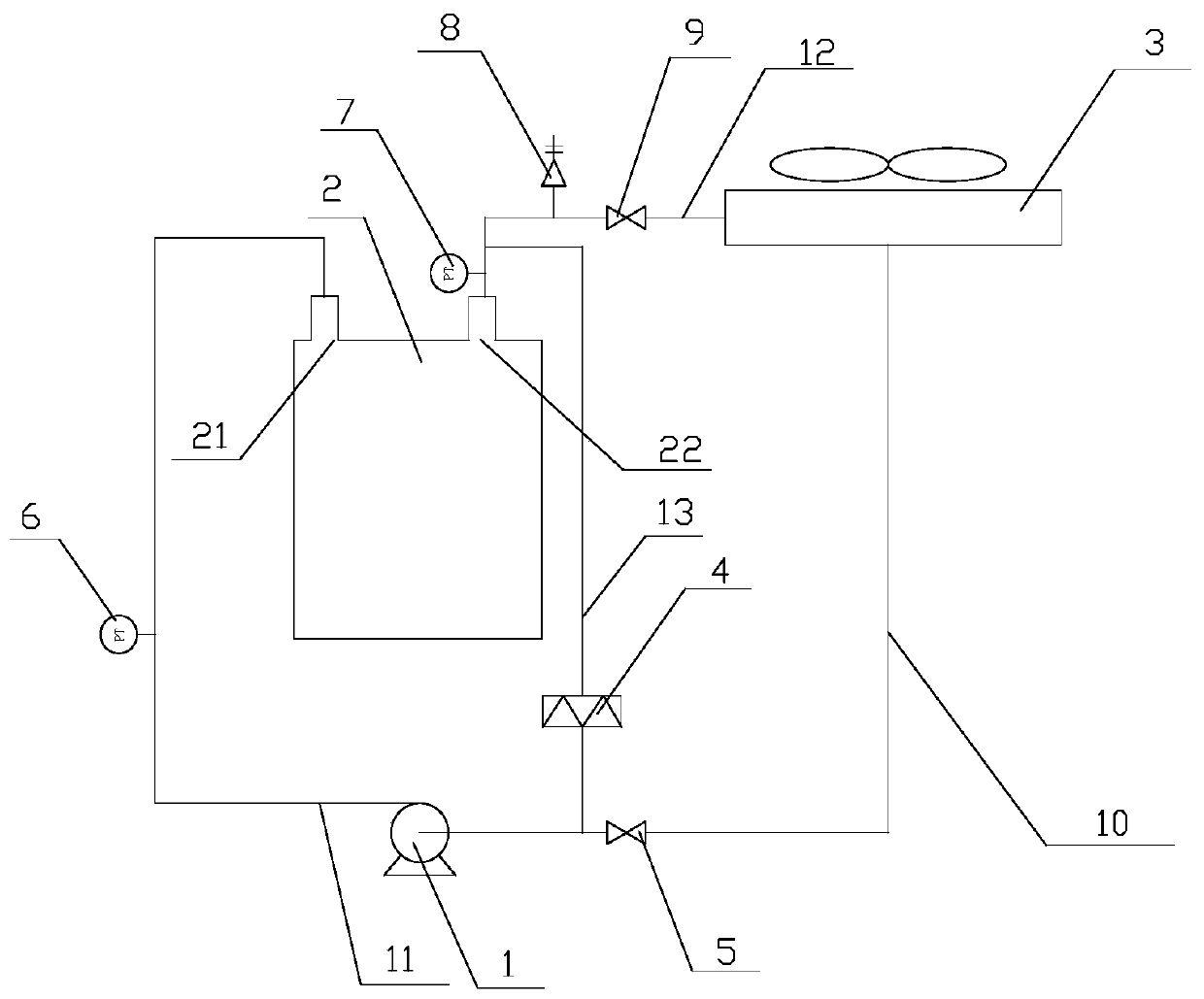

[0017] Please refer to figure 1 , Embodiment 1 of the present invention provides a fuel cell cooling system using an organic working medium, including a circulation pump 1, a fuel cell stack 2, a condenser 3, a PTC heater 4, and a data receiving device (not shown in the figure) and the control device, the circulation pump 1 is used to provide flow power and pressure for the fuel cell cooling system; the condenser 3 can use forced air cooling to condense the gaseous coolant flowing into it into a liquid coolant, and the condenser 3 can be each A kind of air-cooled or liquid-cooled heat exchange equipment; PTC heater 4 has constant temperature heating characteristics, the principle is that after the PTC heating plate is powered on, the self-heating temperature will increase the resistance value and enter the transition zone, and the surface temperature of the PTC heating plate will remain constant. , the temperature is only related to the Curie temperature of the PTC heating pla...

Embodiment 2

[0023] The only difference between the second embodiment of the present invention and the first embodiment is that an exhaust hole is provided on the fuel cell stack 2 at a position opposite to the water outlet 22 , the exhaust hole is communicated with the outlet of the condenser 3 , and the water outlet 22 Connected to one end of the PTC heater 4, the gaseous coolant flowing out of the fuel cell stack 2 flows into the condenser 3 through the exhaust hole to be condensed, and the liquid coolant flowing out of the fuel cell stack 2 flows out from the water outlet 22, Under the action of the circulating pump 1 , it returns to the fuel cell stack 2 .

[0024] The fuel cell cooling system provided by the present invention can automatically control the fuel cell stack 2 to react at a suitable temperature, so as to prolong the service life of the fuel cell stack 2; the present invention uses the phase change heat of the organic working medium to replace the traditional water display...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com