An Operational Risk Modeling Method for Polymorphic Manufacturing System Based on Operational Data Fusion

A manufacturing system and operation risk technology, applied in the field of multi-state manufacturing system operation risk modeling, can solve the problem that intermediate indicators are not fully utilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

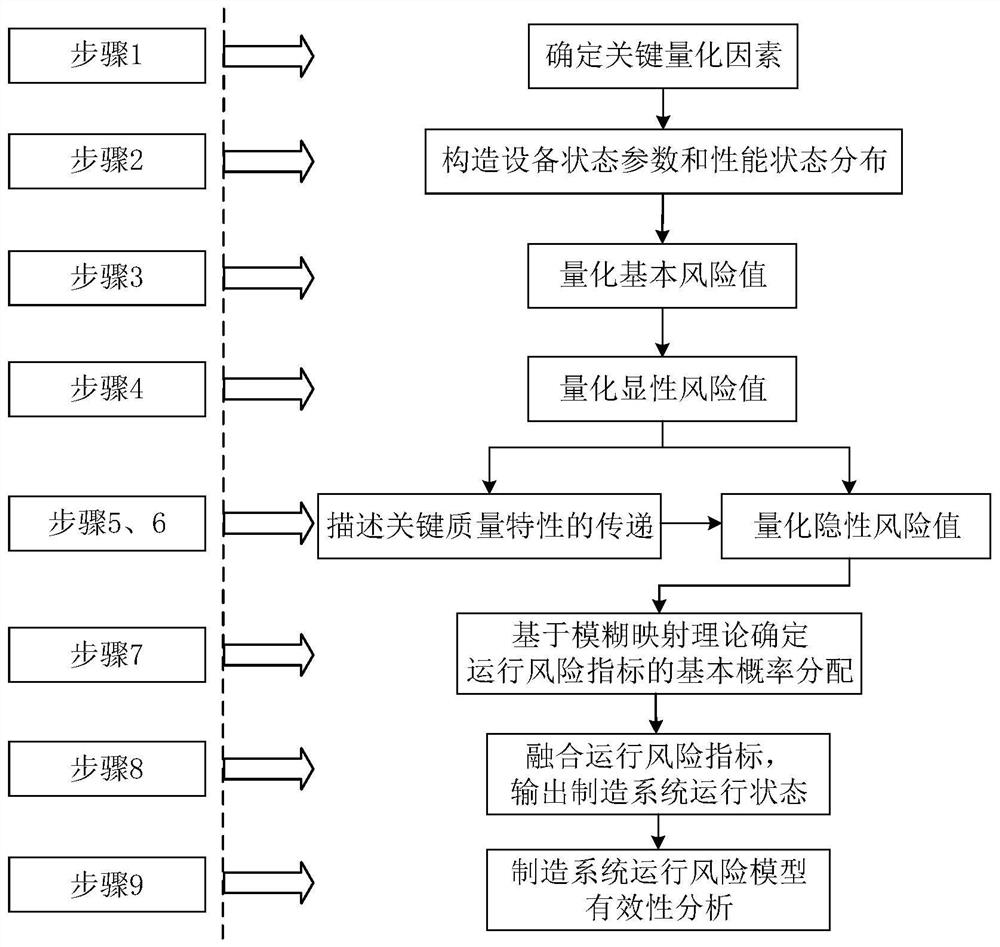

[0059] The present invention is a multi-state manufacturing system operation risk modeling method based on operation data fusion, see figure 1 As shown, the steps are as follows:

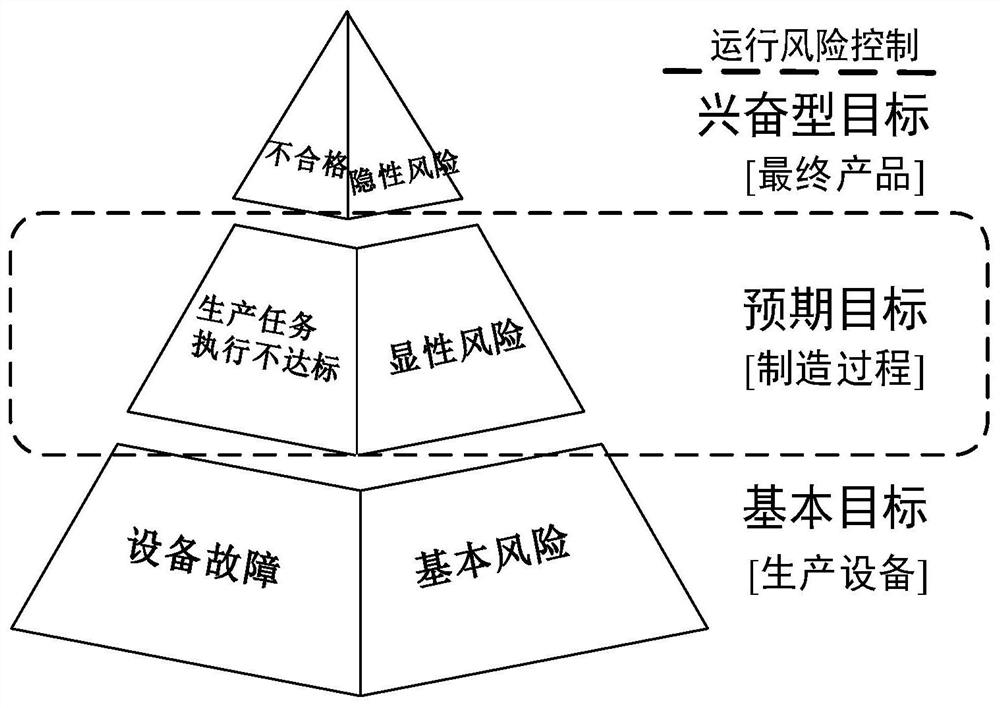

[0060] Step 1 Collect key information on the cylinder head plate manufacturing process of a certain type of eight-cylinder engine, and determine five main processing processes. For the modeling process based on operational risks, see figure 1 , carry out relevant data screening, classification and storage, and analyze its operational risk level, see figure 2 , used in subsequent modeling steps.

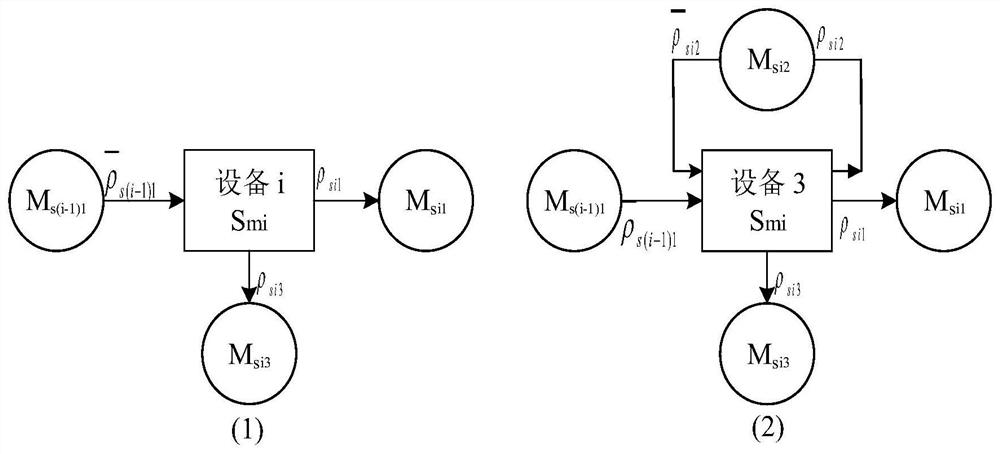

[0061] The simplified manufacturing system model in step 2 consists of two types of equipment, see image 3 (1) and image 3 As shown in (2), the device 3 has a rework process, and compared with other devices, there is one more parameter M s32 . Input parameters The sum o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com