Complex part numerical control technology optimization and adjustment method facing technology reuse

A technology for complex parts and process optimization, applied in the field of CNC process optimization and adjustment, can solve problems such as low efficiency, and achieve the effect of improving the utilization of tool processing capabilities, enhancing practicability, and high-efficiency CNC process solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

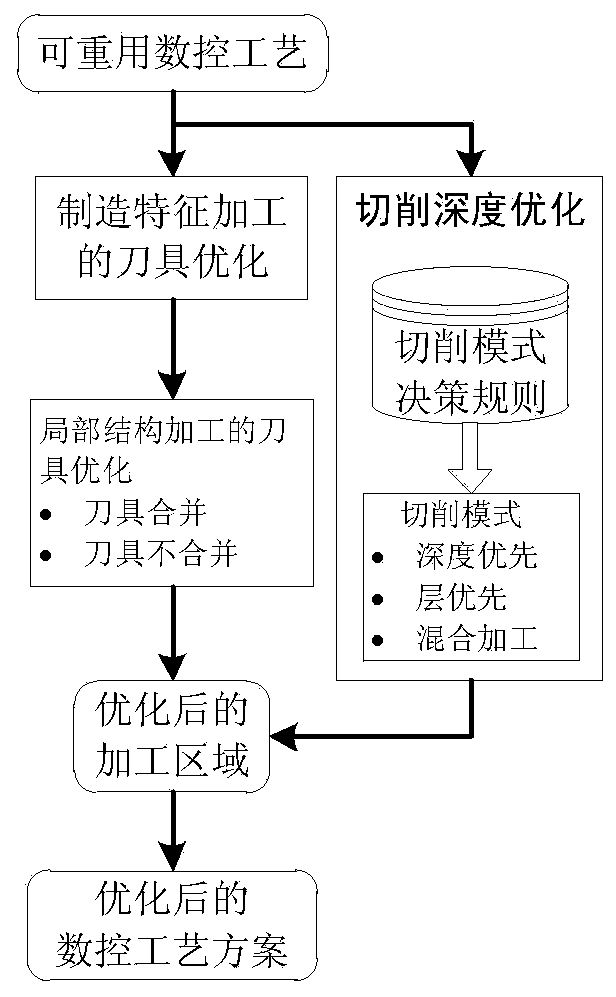

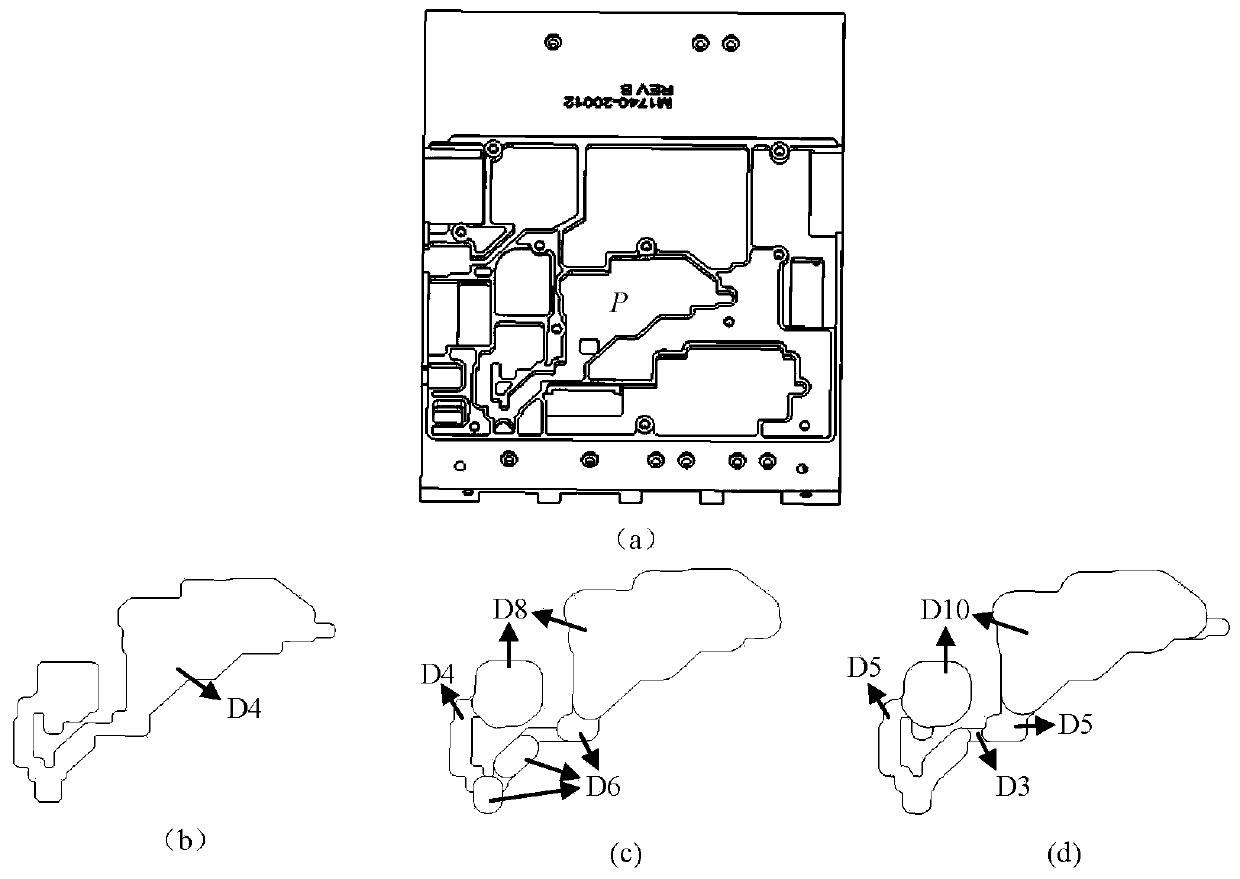

[0051] refer to Figure 1-6 . The specific steps of the method for optimizing and adjusting the numerical control process of complex parts oriented to process reuse in the present invention are as follows:

[0052] 1. Tool optimization adjustment for manufacturing feature processing.

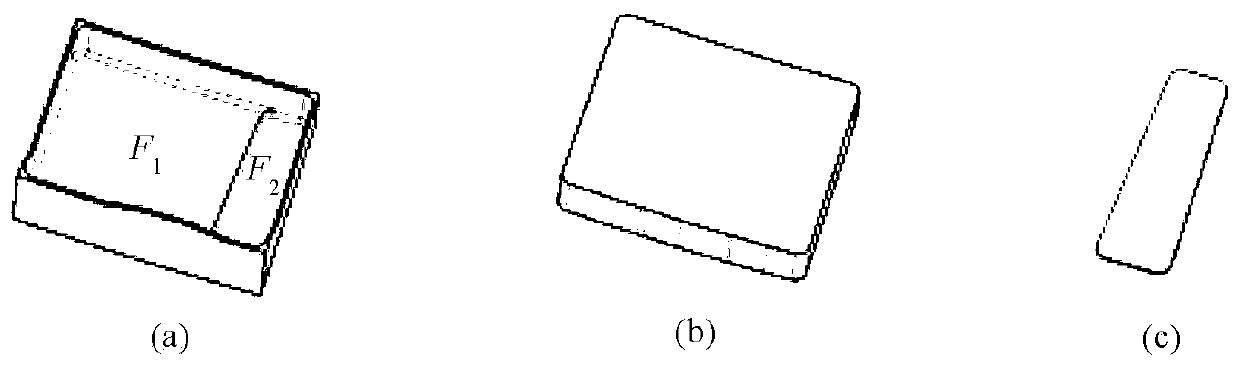

[0053] Step 1) Divide the entire manufacturing feature into multiple processing areas according to the machining capability of the tool and the geometric characteristics of the manufacturing feature. For each processing area divided by complex features, it contains multiple sub-processing areas, and corresponds to certain geometric characteristics and processing strategies. At the same time, a processing operation is correspondingly generated in the CAM system, so the complex feature F is expressed as

[0054]

[0055] MR=T∪M S ∪D G

[0056] Among them, O is the number of divided processing areas, MR k is the kth processing area. MR is the processing area, T is the processing tool, M ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com