Moving formwork and pouring method for pouring tunnel center ditch

A technology for moving the formwork and the center of the tunnel, which is applied in the direction of tunnels, tunnel lining, drainage, etc., can solve the problems of high labor intensity, complicated procedures, and long cycle time, so as to reduce labor intensity, improve pouring efficiency, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

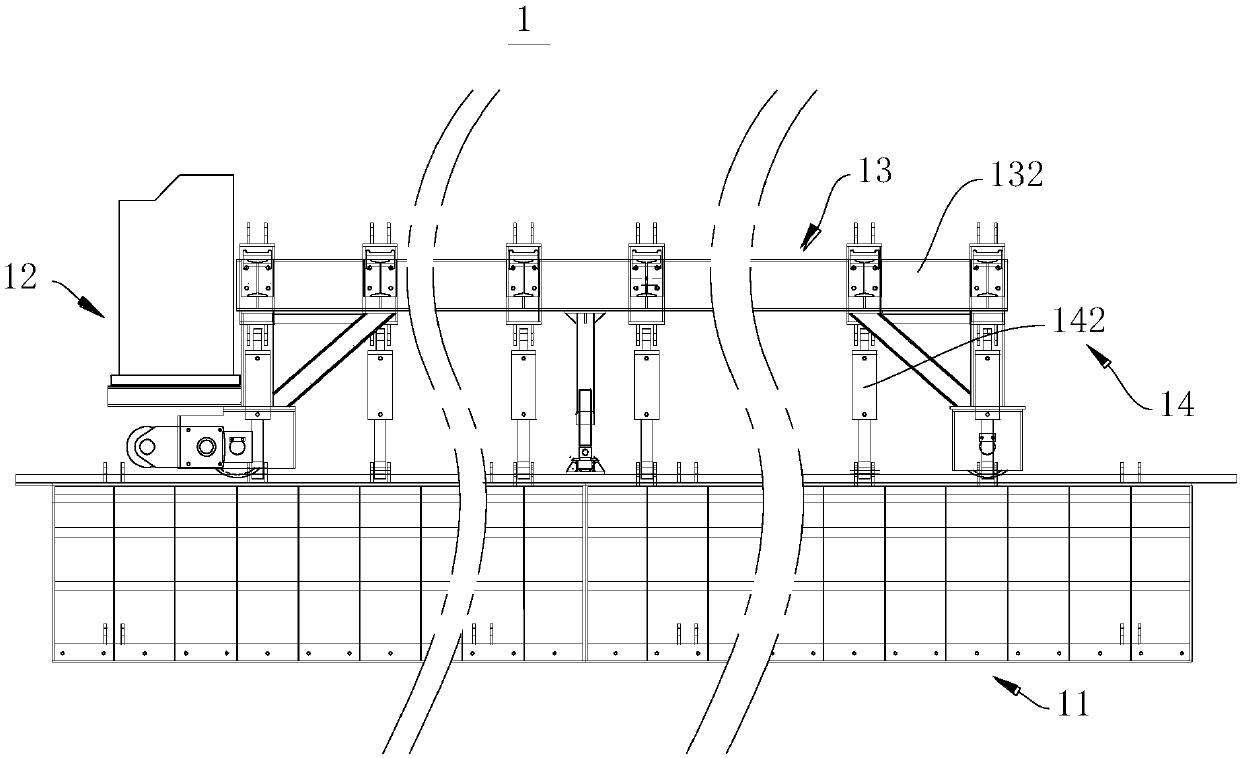

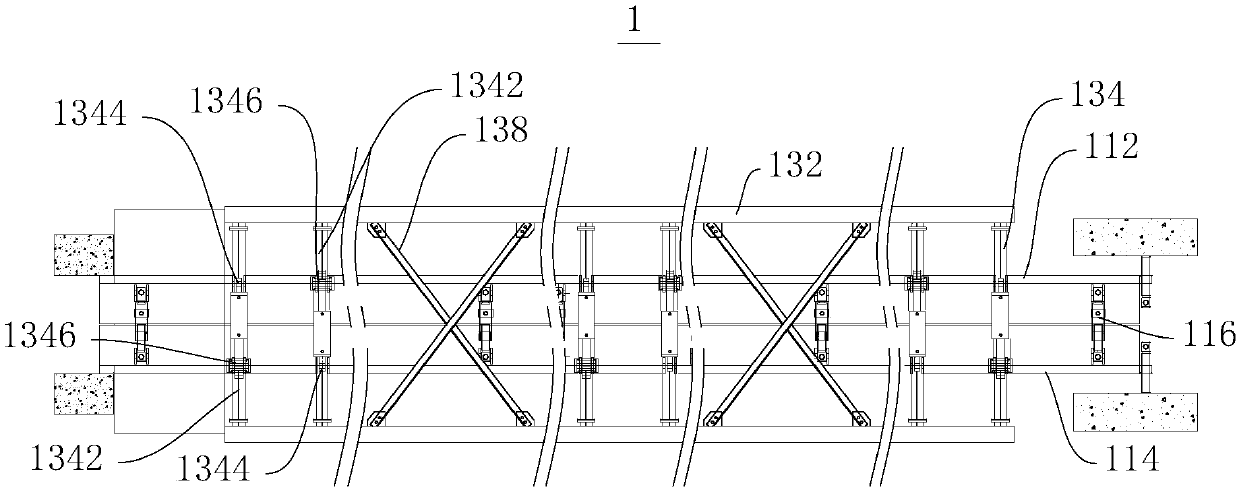

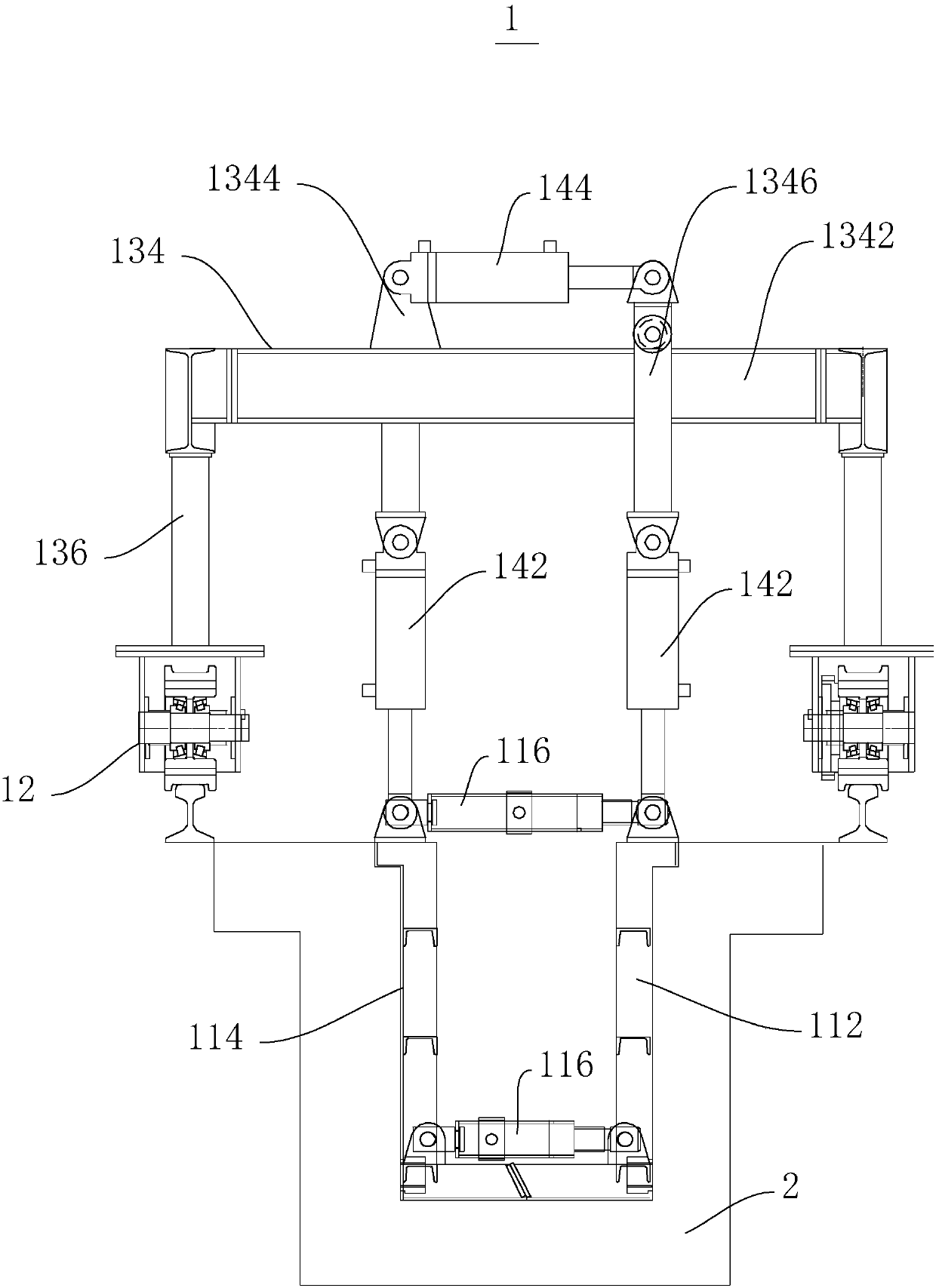

[0041] see Figure 1-Figure 4 , the present invention provides a mobile formwork 1 for pouring the central water ditch of the tunnel. This mobile mold base 1 includes a mold assembly 11 , a traveling assembly 12 , a bracket assembly 13 and a positioning assembly 14 . The mold assembly 11 is used to cooperate with the formed area to form a space to be poured, the walking space is used to drive the movable mold base 1 to move, the bracket assembly 13 is used to support the mold assembly 11, and the positioning assembly 14 is used to make the mold assembly 11 relative to the bracket assembly. 13 produces relative movement.

[0042] The mold assembly 11 includes a first die plate 112 , a second die plate 114 and a telescopic piece 116 .

[0043] The first template 112 and the second template 114 are disposed opposite to each other, and an area to be poured is formed between the first template 112 , the second template 114 and the formed area. One end of the telescopic element 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com