Luminous floor tile

A technology of floor tiles and light-transmitting resin, which is applied to semiconductor devices of light-emitting elements, light sources, lighting and heating equipment, etc., can solve the problems of short circuit, floor tile module replacement, slow installation progress, etc., to achieve uniform heat dissipation and alleviate impact force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

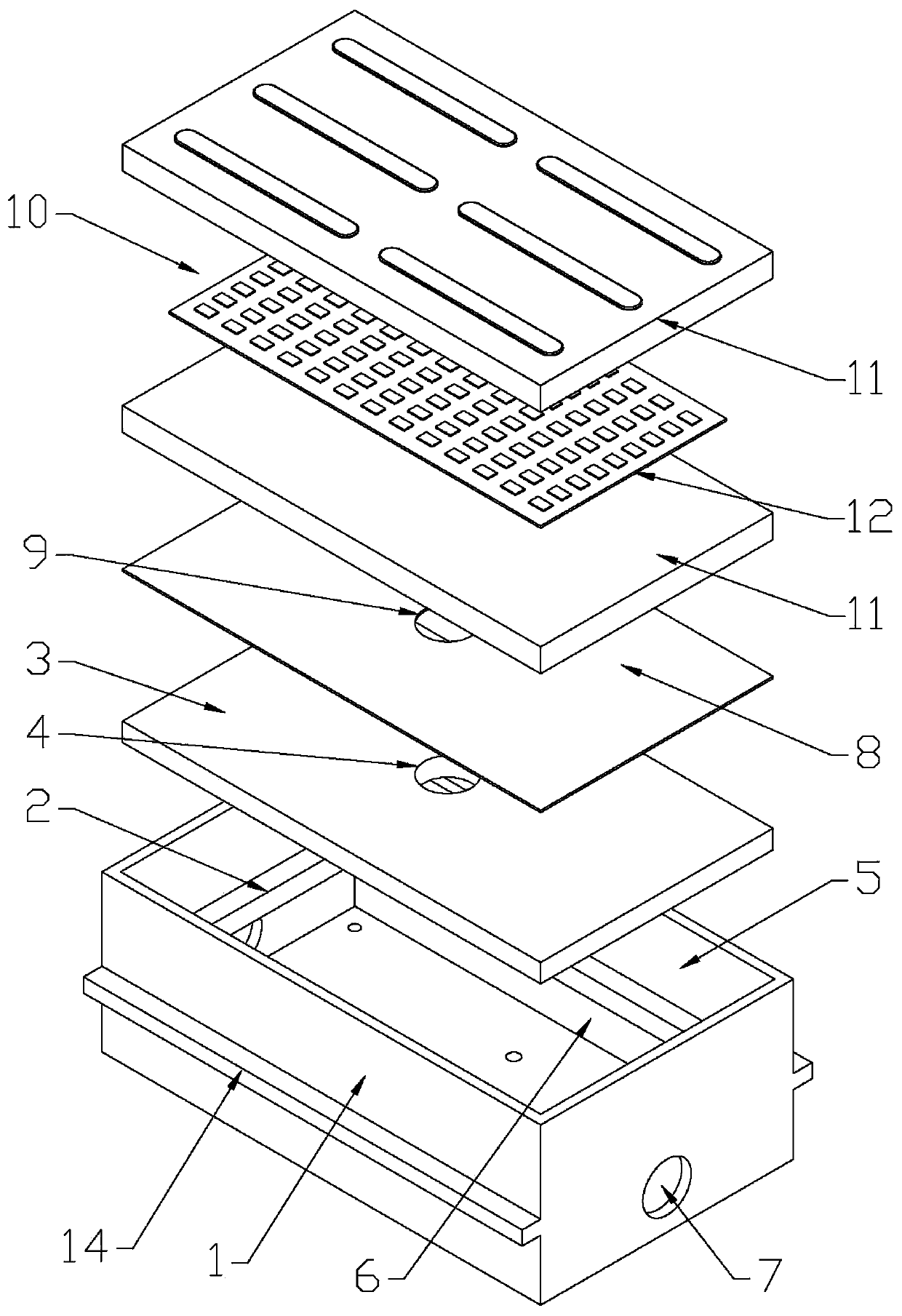

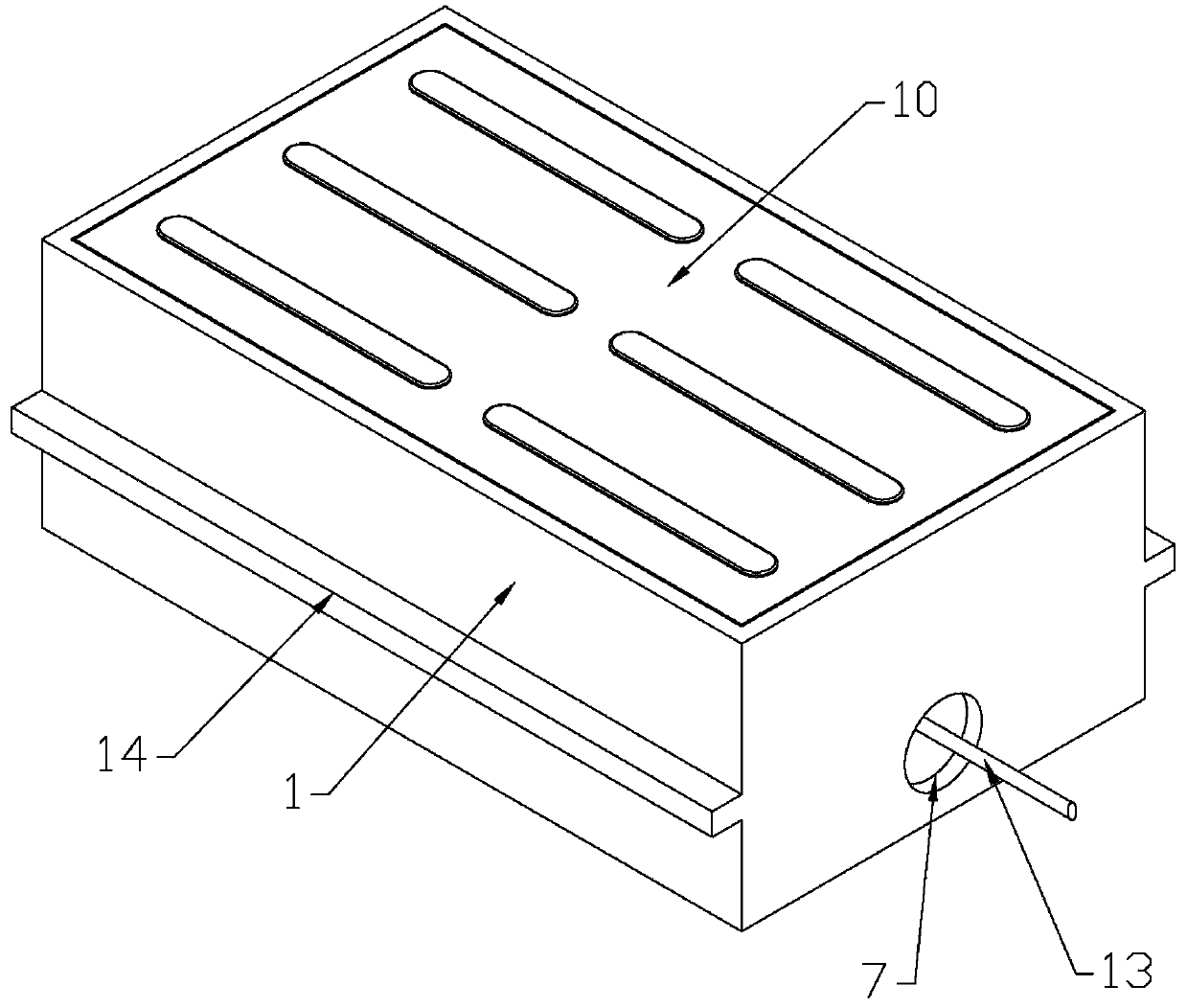

[0034] Such as Figure 1-2, as shown in 6-9: a kind of luminous floor tiles, including a mounting seat 1 and a floor tile module 10, the floor tile module 10 is composed of a light-transmitting resin block 11 and an LED light-emitting plate 12 packaged in the light-transmitting resin block 11, the light-transmitting The resin block 11 is made of resin material. The LED light-emitting board 12 is packaged inside the light-transmitting resin block 11, and the cable 13 of the LED light-emitting board 12 is led out through the light-transmitting resin block 11 downwards. The cable 13 is used for connecting External power supply and external intelligent controller; the mounting base 1 is a hollow body made of pressure-resistant material, and the inner cavity wall of the mounting base 1 is provided with a support boss 2 for supporting the pressure bearing plate 3. The plate 3 is provided with a pressure plate wire hole 4 for the cable 13 to pass through, and the pressure plate 3 div...

Embodiment 2

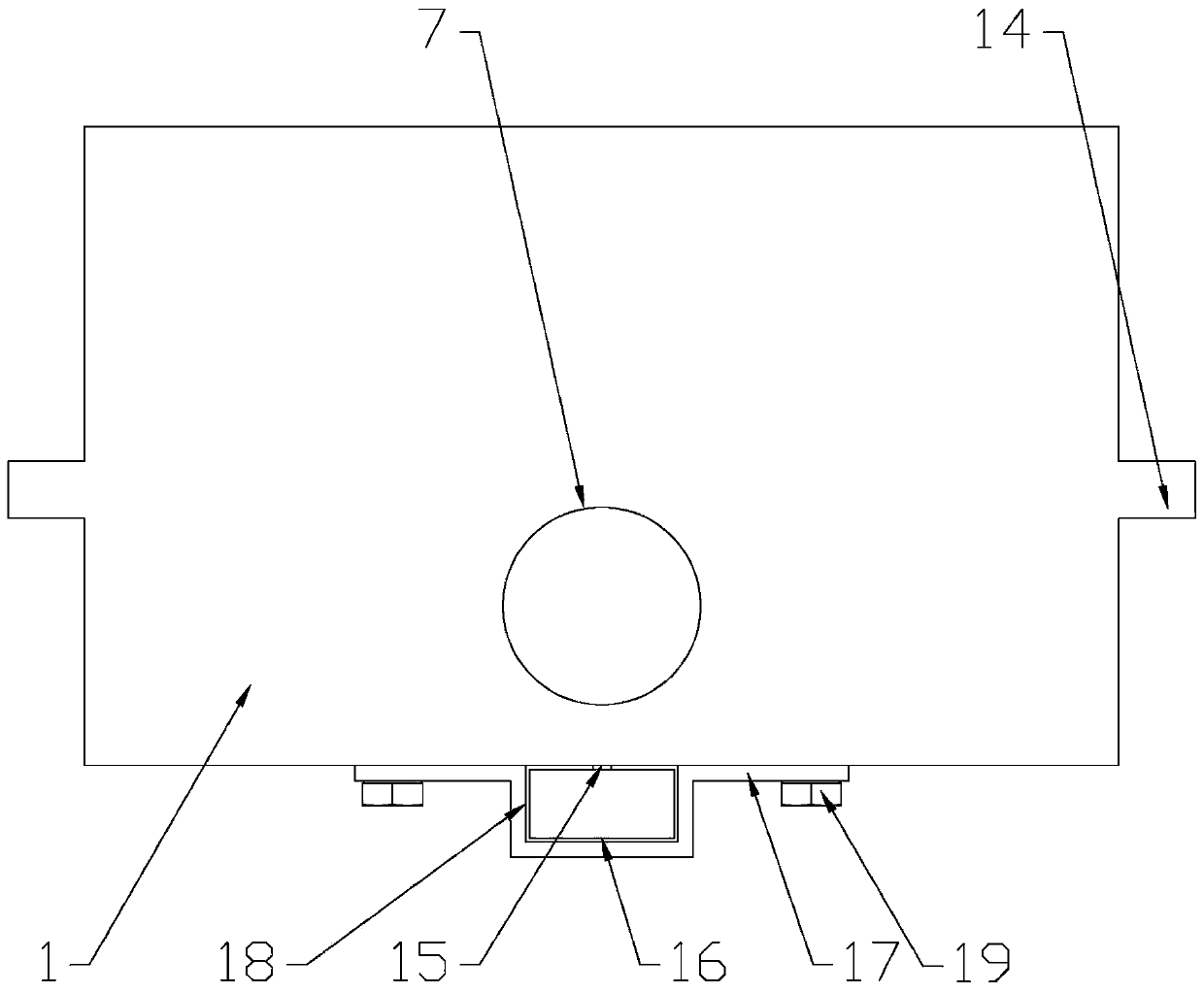

[0039] Such as image 3 , 5 -9 shows: on the basis of Embodiment 1, a permeable hole 15 is provided on the bottom plate of the mounting seat 1, and a drainage pipe 16 fixed on the mounting seat 1 is provided below the mounting seat 1 corresponding to the water permeable hole 15. The drain pipe 16 is a square steel pipe and the drain pipe 16 is provided with a water inlet corresponding to the permeable hole 2. The water outlet of the above drain pipe 16 is arranged at the seepage well; The bottom and the hoop 17 are fixed on the bottom of the mounting base 1 by hoop bolts 19 , the above hoop 17 is provided with a groove 18 for accommodating the drain pipe 16 and the upper edge of the groove 18 is flush with the bottom surface of the mounting base 1 .

[0040] Such as Figure 5-6 , 8-9: when multiple mounting bases 1 are arranged continuously, the drain pipe 16 can connect the multiple mounting bases 1 in series. Moreover, the serial connection of a plurality of mounting base...

Embodiment 3

[0043] Such as Figure 4-9 As shown: on the basis of Embodiment 1, angle steels 20 capable of fixing each mounting seat 1 are respectively provided at the outer walls on both sides of the bottom of each mounting seat 1, so that each mounting seat 1 can be positioned on the same straight line and set location. The angle steel 20 is arranged along the length direction of the installation base 1 and the angle steel 20 is fixed on the bottom plate of the installation base 1 by angle steel bolts 21 . The L-shaped angle steels 20 are parallel and symmetrically arranged on both sides of the mounting base 1 and partially wrap the long side walls and the bottom plate of the mounting base 1 . Furthermore, the serial connection of a plurality of mounting bases 1 can improve the stability of the floor tile module after the embedding, and prevent adverse situations such as deviation of the mounting bases 1 from occurring. The number of multiple mounting seats 1 arranged in the same direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com