Fastening type sand box cover

A sand box cover and snap-on technology, which is applied in the field of rail transit vehicles, can solve the problems of large operating space of the sand box cover, failure to release the pressure of the sand box cover, and excessive pressure of the sand box, so as to achieve small space occupation and convenient operation , pressure sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

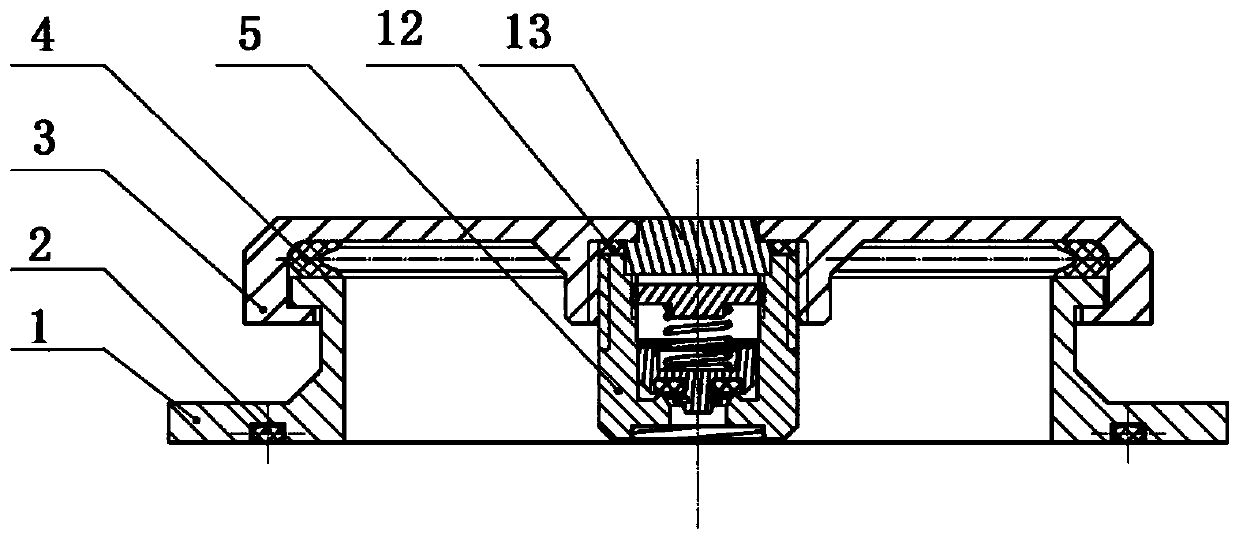

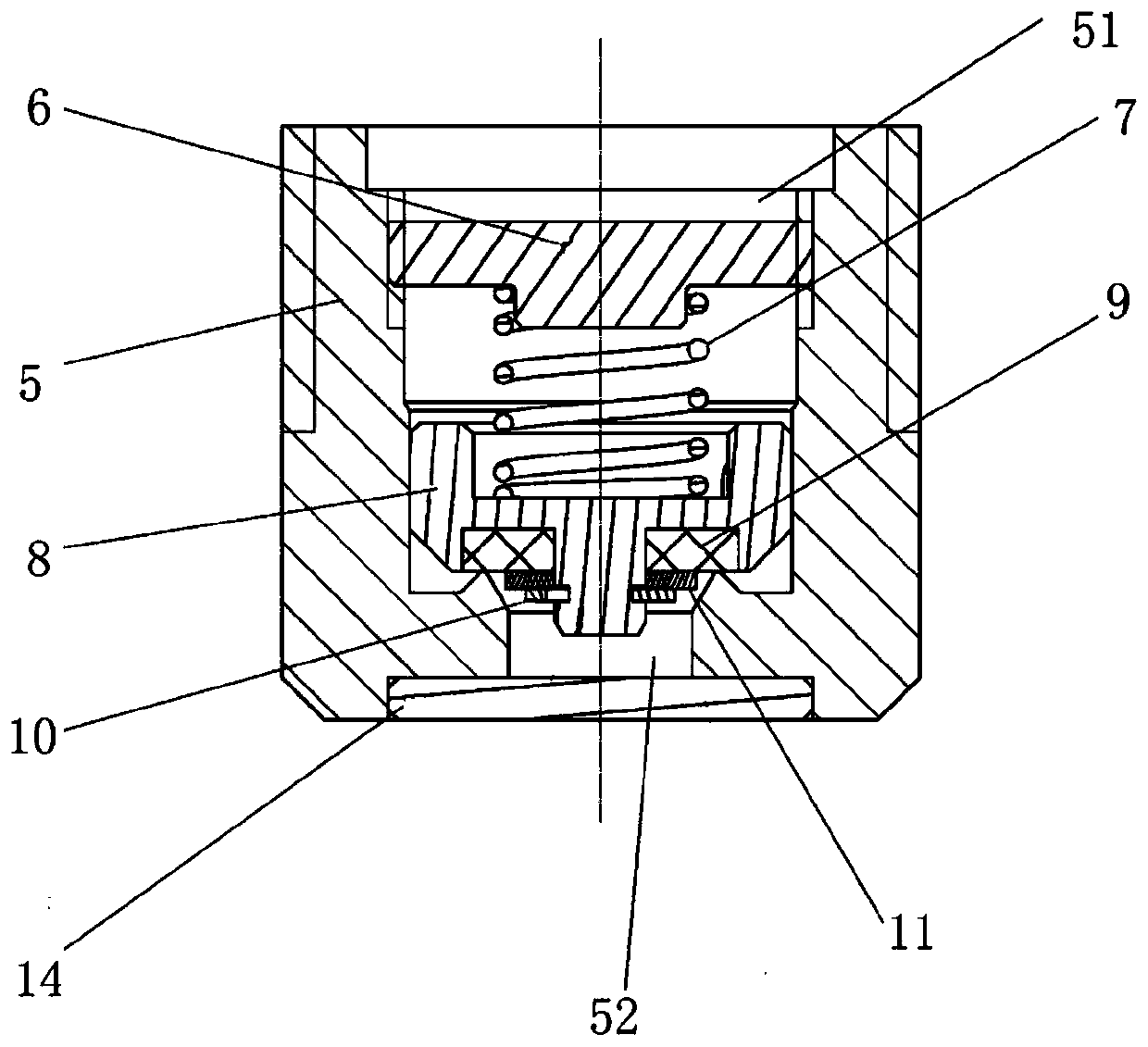

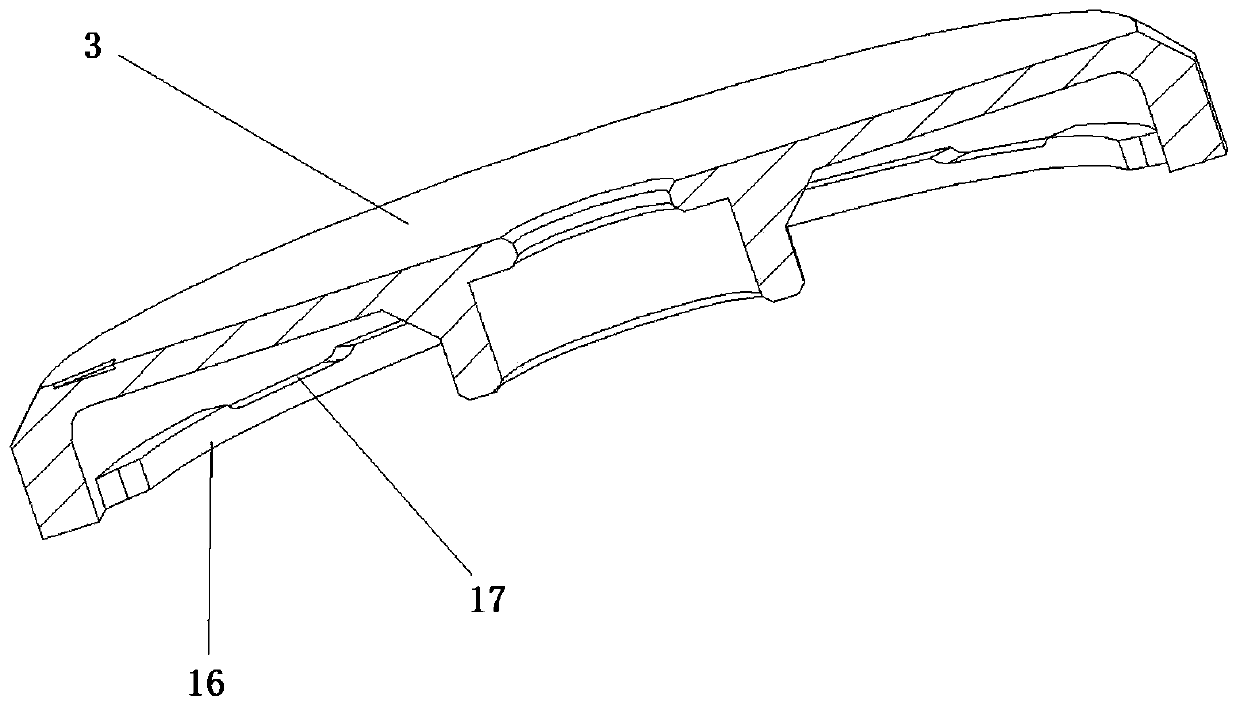

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The structure of a snap-on sand box cover provided by the invention is as follows: Figure 1-2 As shown, including the cover body 3, an overvoltage protection device is installed in the middle of the top of the cover body 3, and the overvoltage protection device is fixedly connected to the cover body 3 through the pressure maintaining mounting seat 5, and an exhaust passage 51 is left inside the pressure maintaining mounting seat 5 , one end of the exhaust channel 51 communicates with the atmosphere and the other end is connected with the pre-exhaust port 52, the exhaust channel 51 is provided with an adjustment piece 6, the adjustment piece 6 is movably connected with one end of the pressure holding seat 8 through the spring 7, and the pressure holding seat 8 The other end is fixedly connected with the first sealing ring 9 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com