Spiral plate end surface welding device

A welding device and spiral plate technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to meet the needs of spiral welding track welding, easy occurrence of internal injuries at splices, discontinuous welding process, etc. Welding quality, avoiding mechanical wear, the effect of fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

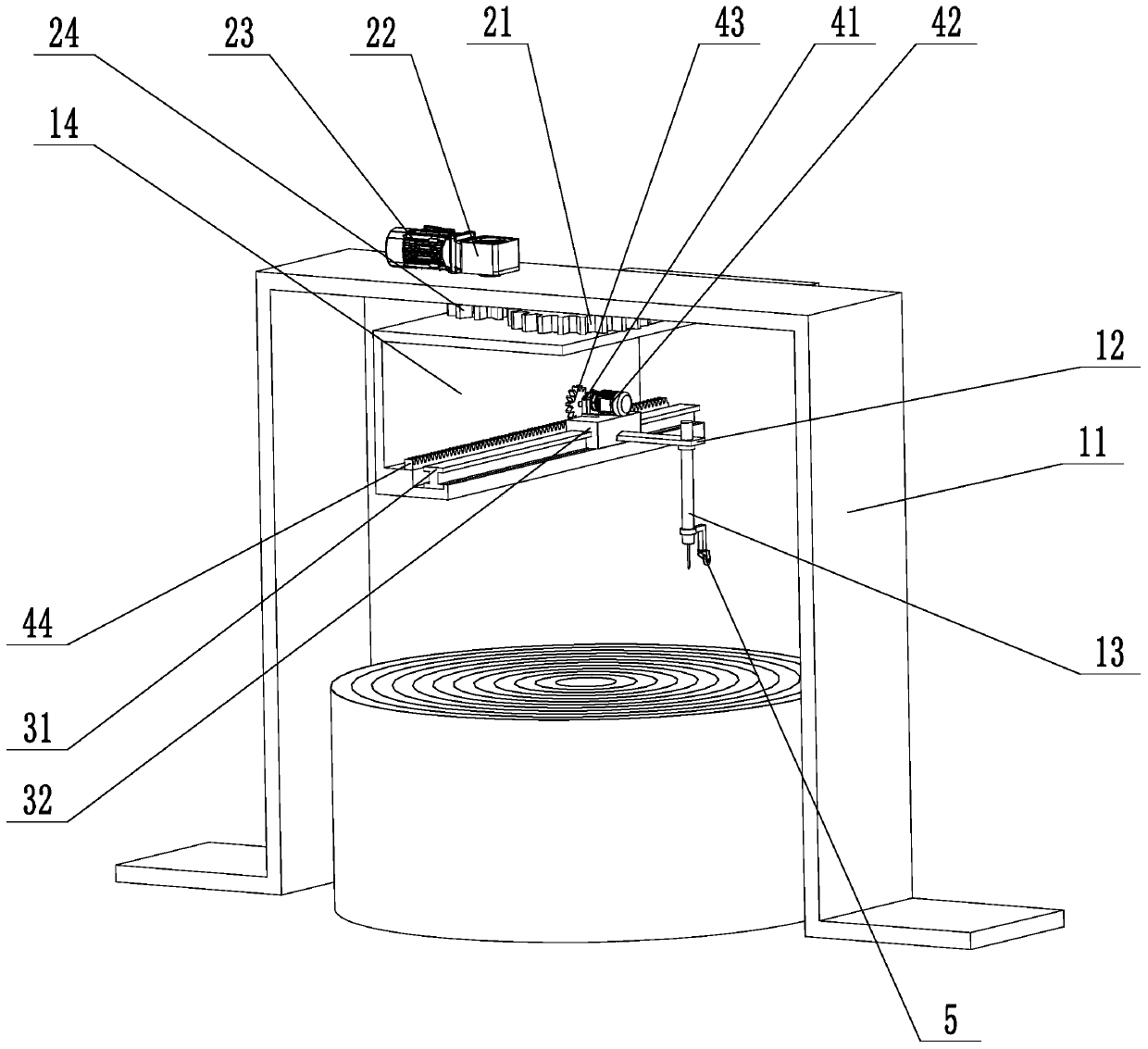

[0049] refer to figure 1 and Figure 5 ( Figure 5 The horizontal linear module section in the figure 1 The horizontal linear module part in the structure is the same), which is a spiral plate end face welding device disclosed by the present invention, the main body of which is the gantry 11, and the rest of the parts are directly or indirectly installed on the gantry.

[0050] The slewing support 21 is bolted on the gantry 11 , the turntable 14 is bolted on the slewing support 21 , and the turntable 14 is also bolted on the slewing support 21 . The rotary driving device is composed of a rotary reducer 22, a rotary servo motor 23 and a rotary gear 24, wherein the rotary reducer 22 is bolted to the gantry 11, the rotary servo motor 23 is installed on the income end of the rotary reducer 22, and the rotary gear 24 The key is connected to the output shaft of...

Embodiment 2

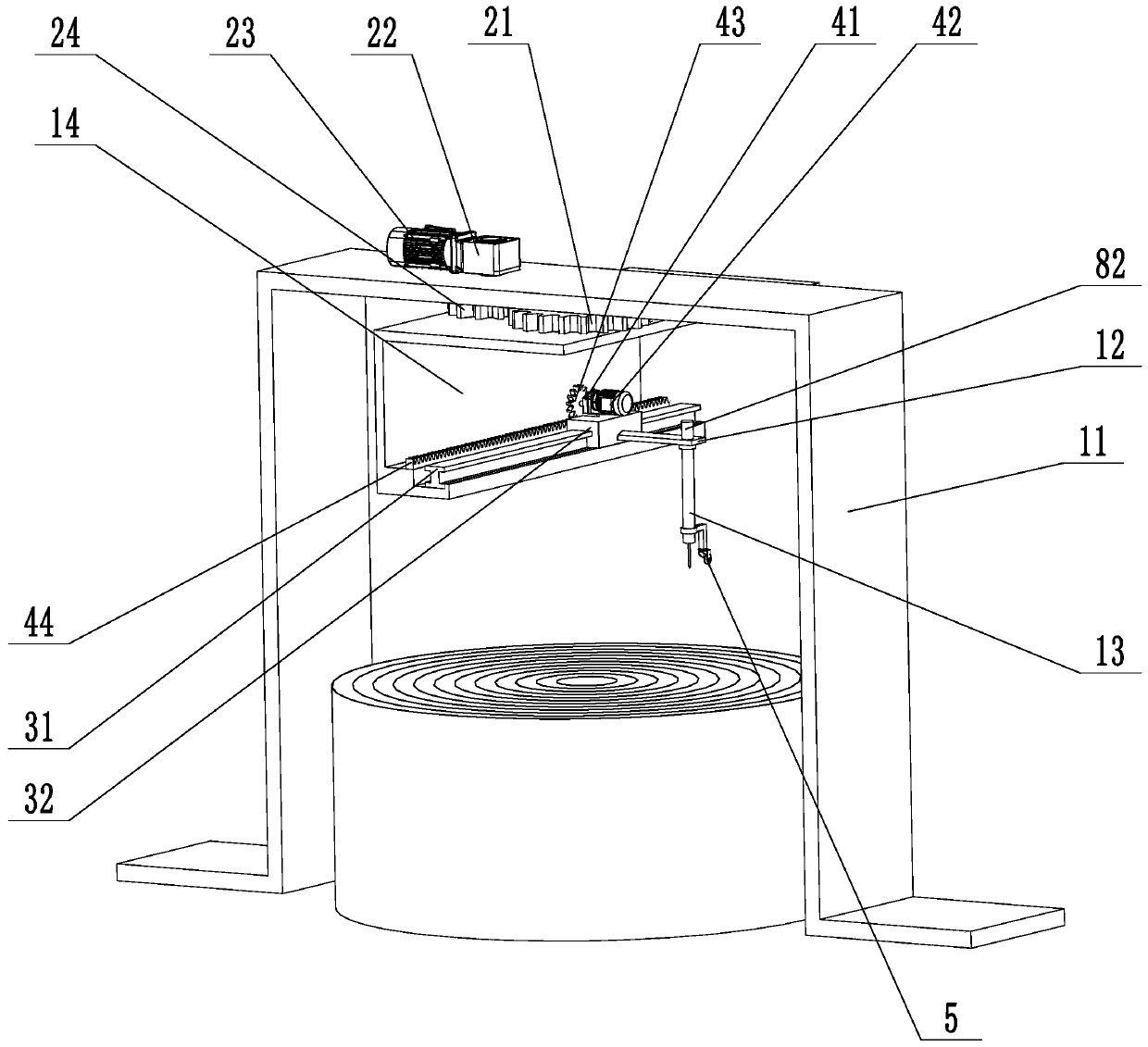

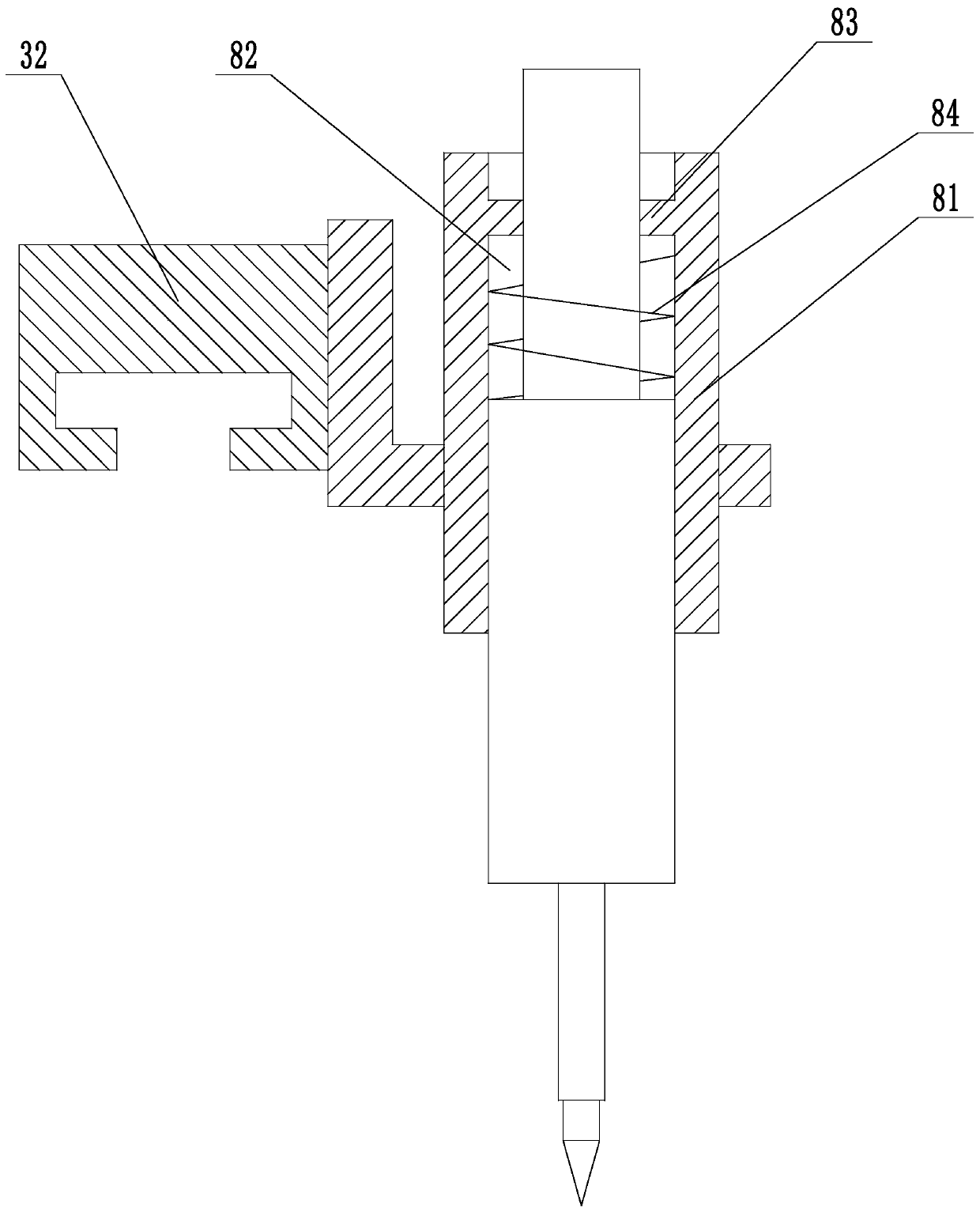

[0066] refer to figure 2 and image 3 In Embodiment 1, the welding torch 13 cannot move in the direction perpendicular to its trajectory, so the distance from the welding seam will be unstable, resulting in fluctuations in the welding height. Therefore, in this embodiment, a fine adjustment device is added between the welding torch 13 and the transverse slider 32 .

[0067] The main part of the fine-tuning device is a guide sleeve 81 fixed on the transverse slider 32, and a hole 82 is arranged on it, and an adjustment spring 84 is placed in the hole 82, and a boss 83 is provided on its inner wall, and the welding torch 13 moves from the bottom to the bottom. and inserted into the hole 82 . The two ends of the adjustment spring 84 respectively bear on the boss 83 and the welding torch 13, and the welding torch 13 slides in the hole 82 after being stressed, and the adjustment spring 84 is elongated or shortened thereupon.

[0068] The working principle of the fine-tuning dev...

Embodiment 3

[0071] refer to Figure 4 and Figure 5 , the welding torch 13 in embodiment 2 can only fluctuate within a small range. When the specification of the spiral plate heat exchanger to be welded changes, an additional corresponding lifting device needs to be added, which will bring additional operating steps. Therefore, this In the embodiment, a longitudinal distance adjustment part is added, and the longitudinal distance adjustment part can adjust the distance between the welding torch 13 and the spiral plate.

[0072] The longitudinal distance adjustment part is composed of a vertical operating table 61, a longitudinal linear module and a longitudinal driving device. Wherein the vertical operating platform 61 is fixed on the horizontal slide block 32 and can move linearly along the horizontal guide rail 31 under the drive of the horizontal slide block 32 .

[0073] The longitudinal linear module is composed of a longitudinal guide rail 62 and a longitudinal slider 63, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com