Flying shear for rolled steel plates

A technology of flying shears and plates, which is applied in the direction of knives, shearing devices, and shearing equipment used in shearing devices. It can solve problems such as time-consuming cleaning, residues falling into gaps, troublesome replacement of flying shears, etc., to achieve extended Effect of service life and reduction of replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

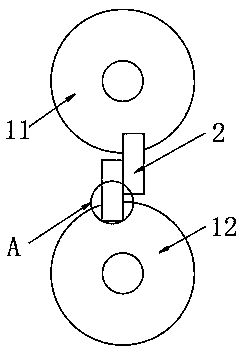

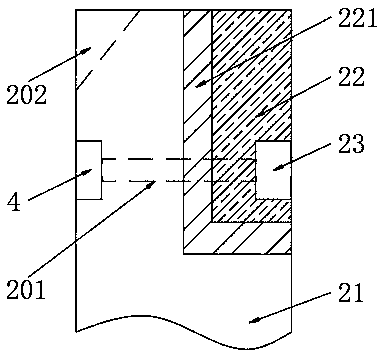

[0027] see Figure 1-5 , the present invention provides the following technical solutions: a flying shear for rolling steel plates, comprising a flying shear rotating roller 1 and a flying shear cutter body 2 installed on the outer wall of the flying shear rotating roller 1, and the flying shear rotating roller 1 includes a first rotating roller 11 and The second rotating roller 12, the first rotating roller 11 and the second rotating roller 12 are equipped with flying scissors body 2, and the two flying scissors bodies 2 are interlaced with each other. and the blade fixed clip 23, the flying scissors carrier 21 is provided with a clip through hole 201, and the blade fixing part 4 is installed in the clip through hole 201, and the flying scissors blade 22 is installed on the flying scissors carrier 21, And the flying scissors blade 22 is equipped with a blade fixing engaging part 23, the flying scissors carrier 21 and the flying scissors blade 22 are fixedly connected by the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com