Monocrystalline silicon high-throughput microneedle structure

A single crystal silicon, high-throughput technology, applied in the direction of drug devices, other medical devices, etc., can solve the problems of inability to complete the injection of liquid medicine, easy to break on the skin, human body intrusion damage, etc., to achieve good consistency and processing costs. The effect of low, high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

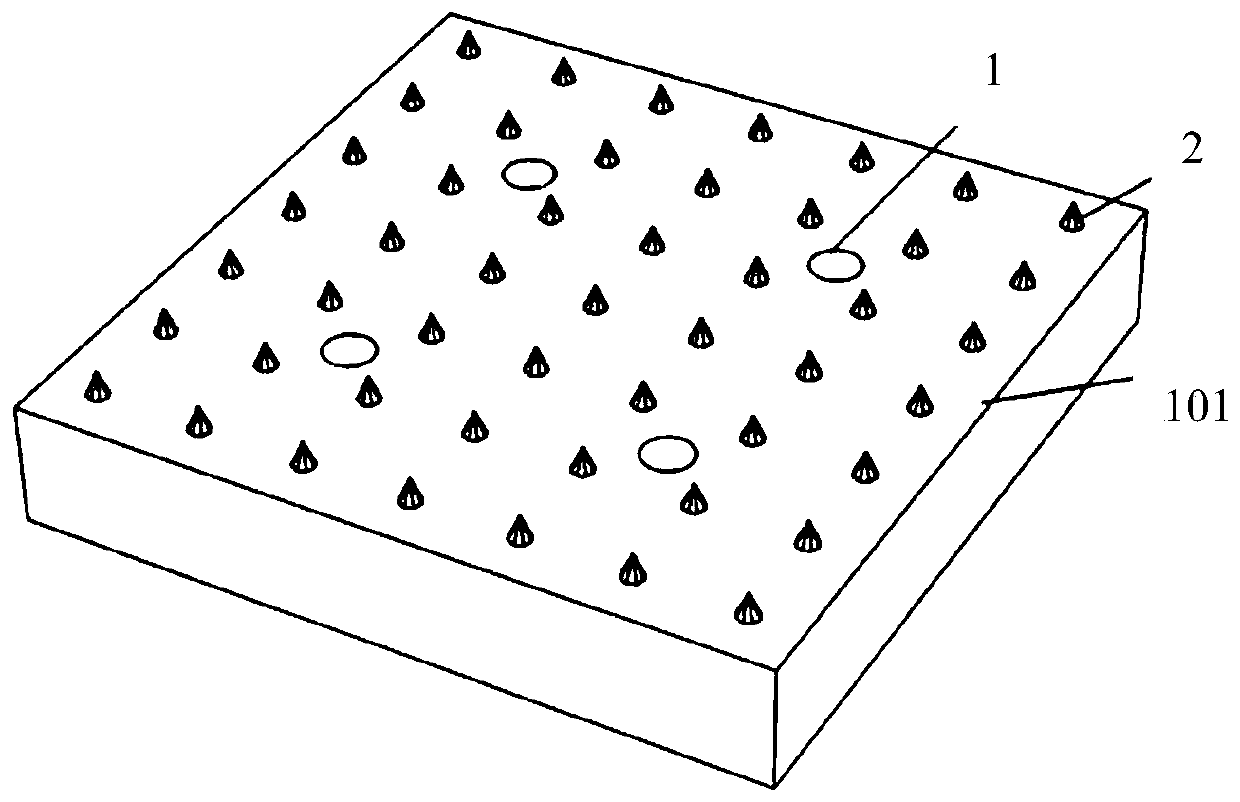

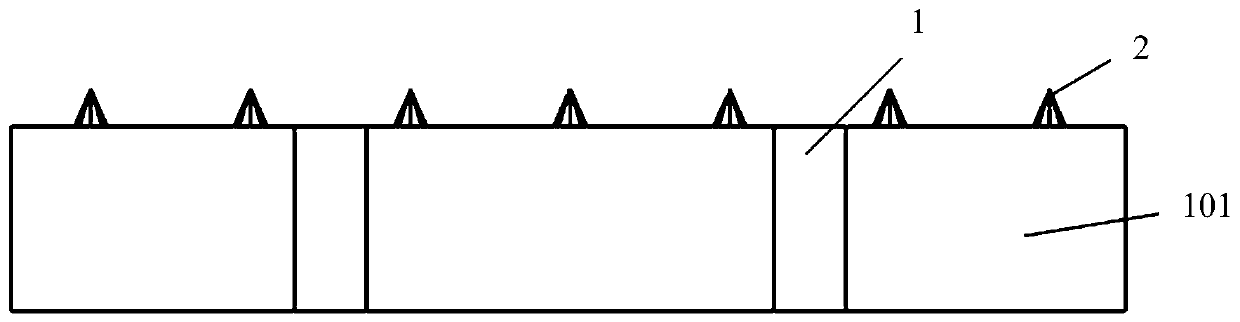

[0050] In this embodiment, the fabrication of monocrystalline silicon high-throughput microneedles with a height of 100-150 μm and a pore diameter of 200-250 μm is taken as an example. Such as figure 1 and figure 2 As shown, a single crystal silicon high-throughput microneedle structure includes a single crystal silicon microneedle array 2, a plurality of flux holes 1 and (100) silicon chips 101, and the single crystal silicon microneedle array 2 and the flux hole 1 are arranged on the (100) silicon wafer 101, the position of the flux hole 1 and the single crystal silicon microneedle array 2 complementarily interfere, and the flux hole 1 The shape is circular, the microneedles in the microneedle array 2 are solid needles 106, the axis of the solid needles 106 is perpendicular to the surface of the (100) silicon wafer 101, and the solid needles 106 are conical shape. The single crystal silicon microneedle array 2 is a square microneedle array.

[0051] In this embodiment, ...

Embodiment 2

[0065] Compared with Example 1, the monocrystalline silicon microneedle array 2 in this embodiment is a honeycomb microneedle array, and a flux is set in a single honeycomb in the honeycomb microneedle array. hole 1. At this time, there are more solid needles 106 near the flux hole 1, and the flux hole 1 can be set larger than that of the embodiment 1, so that the permeability of the medicinal solution is higher.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com