A maintenance and detection method of a radio-frequency power supply

A detection method, a technology of radio frequency power supply, applied in the direction of instruments, digital data certification, etc., can solve the problems of inability to meet customer customization needs, inability to guarantee the quality standard of maintenance products, and poor product compatibility, so as to improve maintenance efficiency and reliability, The effect of reducing the scope of failure and facilitating management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

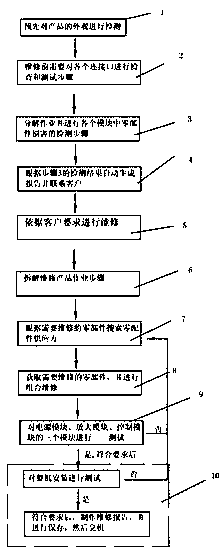

[0038] like figure 1 As shown, the maintenance detection method of a radio frequency power supply provided by this embodiment specifically includes the following steps:

[0039] 1) Check the appearance of the product in advance;

[0040] 2) Inspection and testing steps are required for each connection port before maintenance;

[0041] 3) According to the three modular decomposition operations of power module, amplification module and control module, and carry out the detection steps of component damage in each module;

[0042] 4) Automatically generate reports and contact customers according to the test results in step 3;

[0043] 5) Carry out maintenance according to customer requirements;

[0044] 6) Operation steps for dismantling and repairing products;

[0045] 7) Search spare parts suppliers according to the parts that need to be repaired;

[0046] 8) Obtain the parts that need to be repaired and carry out combined repairs;

[0047] 9) Test the three modules of the...

Embodiment 2

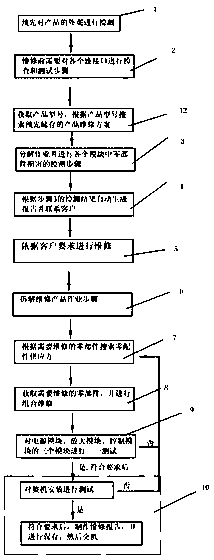

[0050] like figure 2 As shown, in the maintenance detection method of a radio frequency power supply provided by this embodiment, further, step 11 is added to step 2 to obtain the product model, search the pre-stored product maintenance plan according to the product model, and then retrieve the product corresponding to the product model maintenance proposal.

[0051] Further, the product maintenance scheme is a maintenance scheme customized in advance according to all product models.

[0052] Further, the product maintenance plan includes product model, corresponding interface signal requirements, and product QR code.

[0053] Further, the two-dimensional code of the product includes the production date, manufacturer, and maintenance times of the product.

[0054] Further, in step 10, the generated maintenance report is processed with an encryption algorithm, and then sent to the customer.

[0055] Further, the encryption algorithm in step 10 adopts MD5 encryption algorith...

Embodiment 3

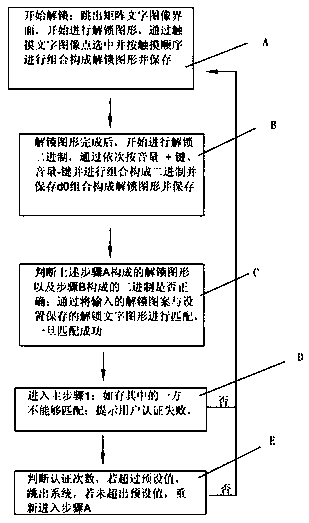

[0057] like image 3 As shown, in the maintenance and detection method of a radio frequency power supply provided by this embodiment, step 12 is added before step 1 to authenticate the user before the maintenance of the product. The specific steps are as follows:

[0058] A) Start unlocking: jump out of the matrix text image interface, start to unlock the graphic, select it by touching the text image and combine it according to the touch sequence to form the unlocking graphic and save it;

[0059] B) After the unlocking graphics are completed, start to unlock the binary, press the volume + key, volume - key and combine them to form a binary and save it;

[0060] C) Judging whether the unlock pattern formed in step A above and the binary pattern formed in step B are correct; by matching the input unlock pattern with the unlock text pattern saved in settings, once the match is successful;

[0061] D) Enter the main step 1; if one of them cannot be matched; the user will be prom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com