Preparation method of metalloporphyrin/carbon nano-tube paper flexible gas sensor

A carbon nanotube paper and gas sensor technology, applied in the direction of material resistance, etc., can solve the problem of low sensitivity, achieve the effect of improving sensitivity, simple and novel preparation method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Take an appropriate amount of tetrakis (4-sulfonate) phenyl porphyrin (tpps 4 ) And cobalt acetate are dissolved in methanol, then heated to 70°C, after reacting for 10 hours, cooled to room temperature. Suction filtration, wash the filter cake with anhydrous methanol, collect the filtrate, use recrystallization and other methods for purification, and dry to obtain cobalt tetra (4-sulfonate) phenyl porphyrin (Co-tpps4).

[0038] (2) Take 0.3g of carbon nanotubes (CNTs) and 0.01g of Co-tpps 4 Ultrasonic dispersion in 30ml ionized water to obtain Co-tpps 4 / CNTs dispersion: Add 2g of paper fiber into 70ml of deionized water, and use high-speed shear to disperse for 12h to obtain a uniform pulp. Co-tpps 4 / CNTs dispersion is mixed with paper pulp, after high-speed shearing and mixing, vacuum filtration, the resulting filter cake is rolled at a pressure of 60MPa and a temperature of 80°C for 6h to obtain Co-tpps 4 / CNTs paper flexible gas sensor.

[0039] Co-tpps that will b...

Embodiment 2

[0042] (1) Take an appropriate amount of tetrakis (4-sulfonate phenyl) porphyrin (tpps 4 ) And zinc acetate dissolved in methanol, then heated to 85°C, reacted for 5 hours, and then cooled to room temperature. Suction filtration, wash the filter cake with anhydrous methanol, collect the filtrate, use recrystallization and other methods to purify, and dry to obtain zinc tetrakis (4-sodium sulfonate phenyl) porphyrin (Zn-tpps 4 ).

[0043] (2) Take 0.15g carbon nanotubes (CNTs) and 0.01g Zn-tpps 4 Ultrasonic dispersion in 40ml ionized water to obtain Zn-tpps 4 / CNTs dispersion: Add 1g of paper fiber to 60ml of deionized water and disperse for 6h by high-speed shearing to obtain a uniform pulp. Zn-tpps 4 / CNTs dispersion is mixed with paper pulp, after high-speed shearing and mixing, vacuum filtration, the resulting filter cake is rolled at 40MPa pressure and 60℃ temperature for 12h, then Zn-tpps is obtained 4 / CNTs paper flexible gas sensor.

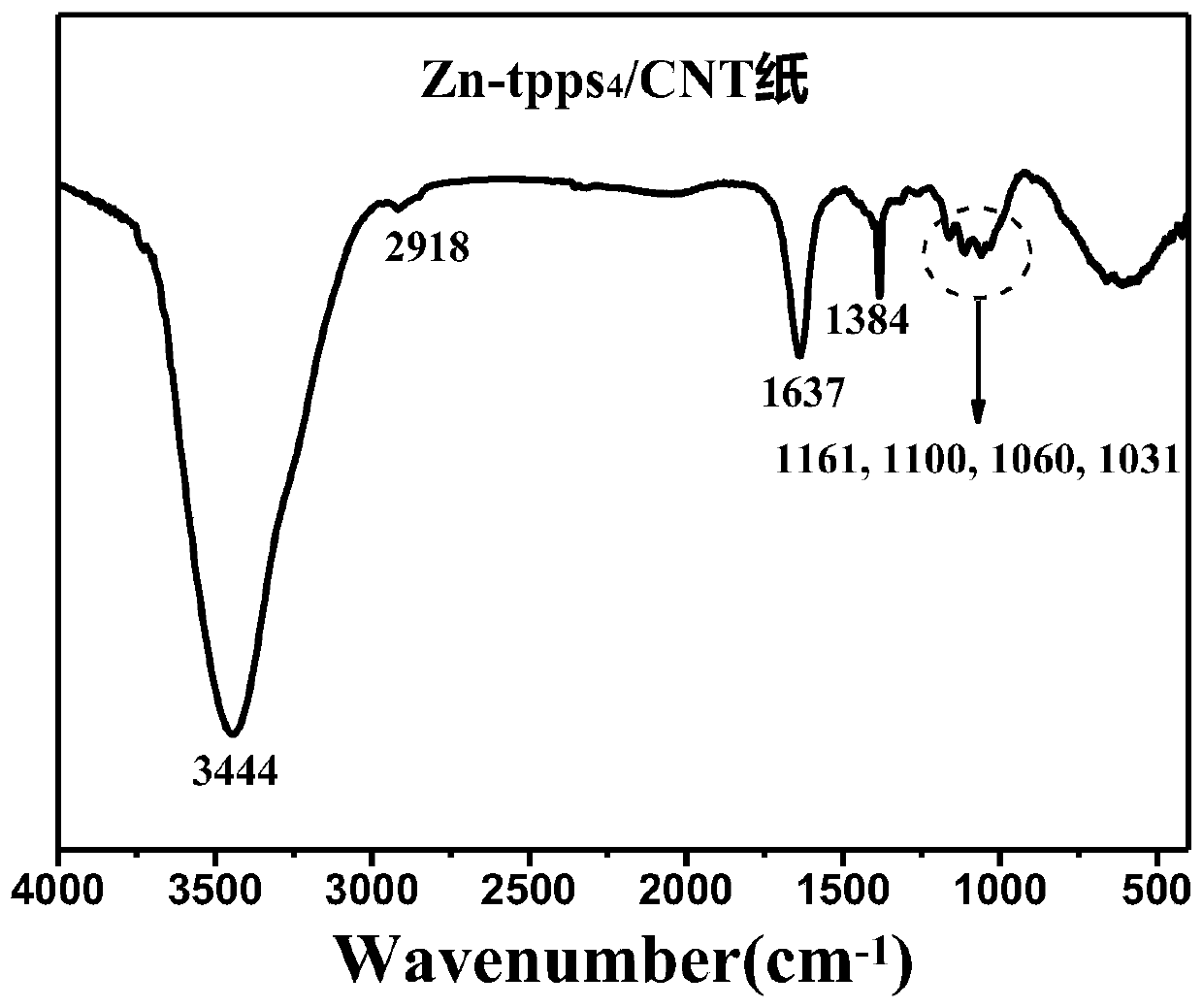

[0044] The prepared Zn-tpps 4 / CNT paper...

Embodiment 3

[0047] (1) Take an appropriate amount of tetrakis (4-sulfonate phenyl) porphyrin (tpps 4 ) And ferric acetate are dissolved in methanol, then heated to 100°C, after reaction for 2h, cooled to room temperature. Suction filtration, washing the filter cake with anhydrous methanol, collecting the filtrate, purifying by means of recrystallization, etc., and drying to obtain iron tetrakis (4-sodium sulfonate phenyl) porphyrin (Fe-tpps4).

[0048] (2) Take 0.05g carbon nanotubes (CNTs) and 0.01g Fe-tpps 4 Ultrasonic dispersion in 50ml ionized water to obtain Fe-tpps 4 / CNTs dispersion: Add 0.5g of paper fiber to 50ml of deionized water, and use high-speed shear to disperse for 2h to obtain a uniform pulp. Fe-tpps 4 / CNTs dispersion is mixed with paper pulp, high-speed shearing and mixing are uniform, vacuum filtration, and the resulting filter cake is pressed and rolled at a pressure of 20MPa and a temperature of 40°C for 24h to obtain Fe-tpps 4 / CNTs paper flexible gas sensor.

[0049] F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com