Method for measuring uniaxial tension large-strain-range hardening curve of metal round bar specimen

A technology of uniaxial stretching and hardening curves, which is applied in measuring devices, mechanical measuring devices, mechanical diameter measurement, etc., can solve the problems of large error, large amount of calculation, cumbersome measurement, etc., to save measurement time and cost and to Measuring the effect of instrumentation on demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

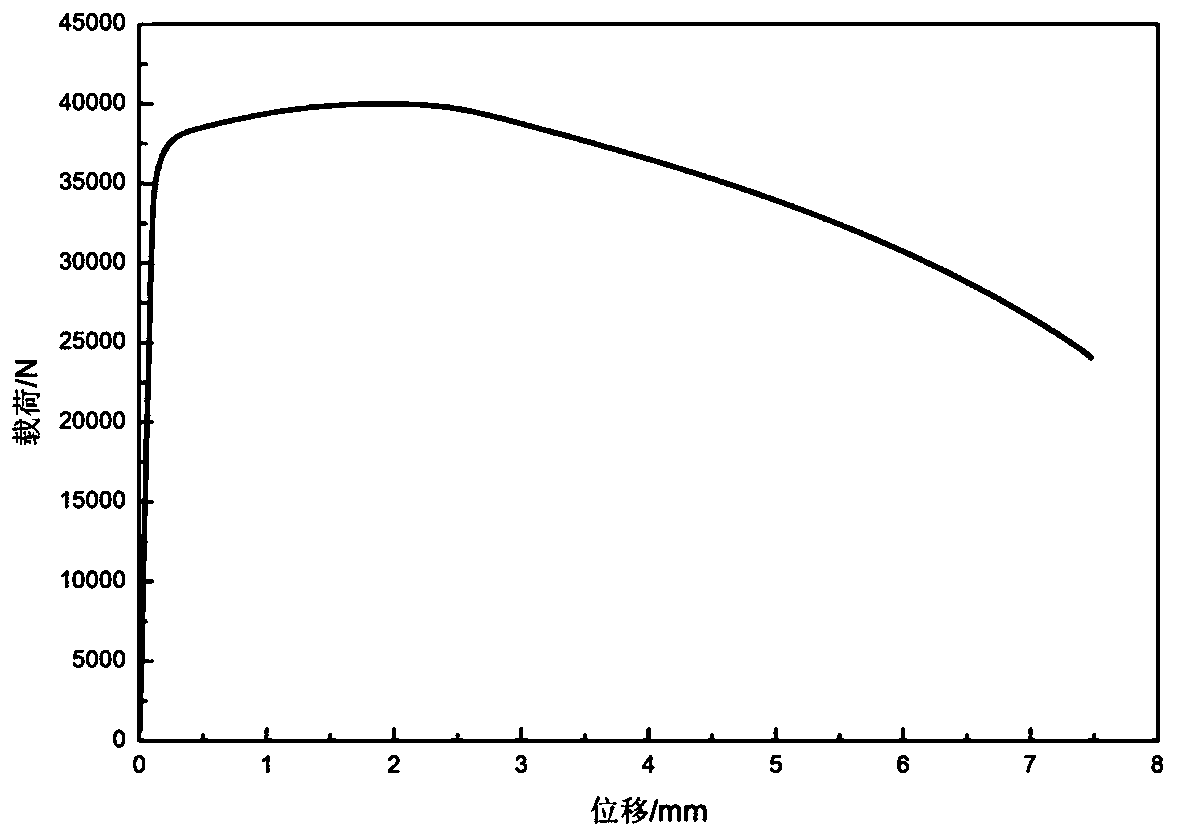

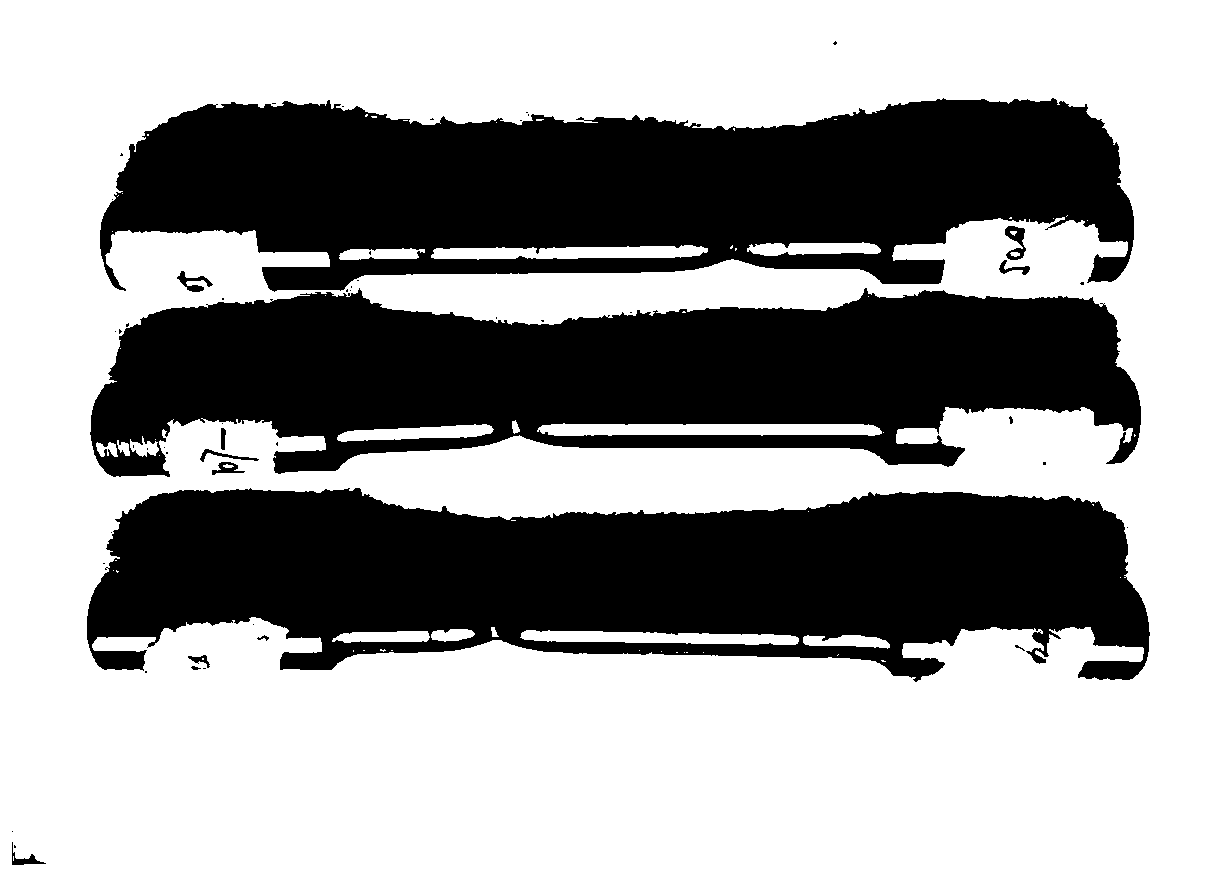

[0043] (1) The present invention carries out the uniaxial tensile test taking the low carbon steel round bar sample as an example. The initial cross-sectional diameter of the round bar sample is 10mm, the gauge length section is 50mm, and the tensile speed is 3mm / min. and the electronic extensometer to measure and record the load and displacement at each moment when the gauge length section of the sample is stretched until it breaks, forming a figure 1 The load-displacement (P-ΔL) curve shown. Tensile fracture specimens such as figure 2 as shown in image 3 As shown, the vernier caliper is used to measure the end face radius of the tensile specimen a f . In addition, optical measurement technology was used to record the geometric profile information of the sample neck in the tensile test, such as Figure 4As shown, the Bridgman method can be used to directly measure the hardening curve in a large strain range for comparison with the method of the present invention. ;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com