Heat insulation device and method

A technology for heat insulation devices and test chambers, which is applied to measuring devices, instruments, vibration tests, etc., can solve the problem that the heat or cold of the test chamber cannot be effectively prevented from being transmitted downwards, so as to reduce the temperature difference between inside and outside and surface condensation or condensation. Frost, protection of test equipment, good promotion of the effect of use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

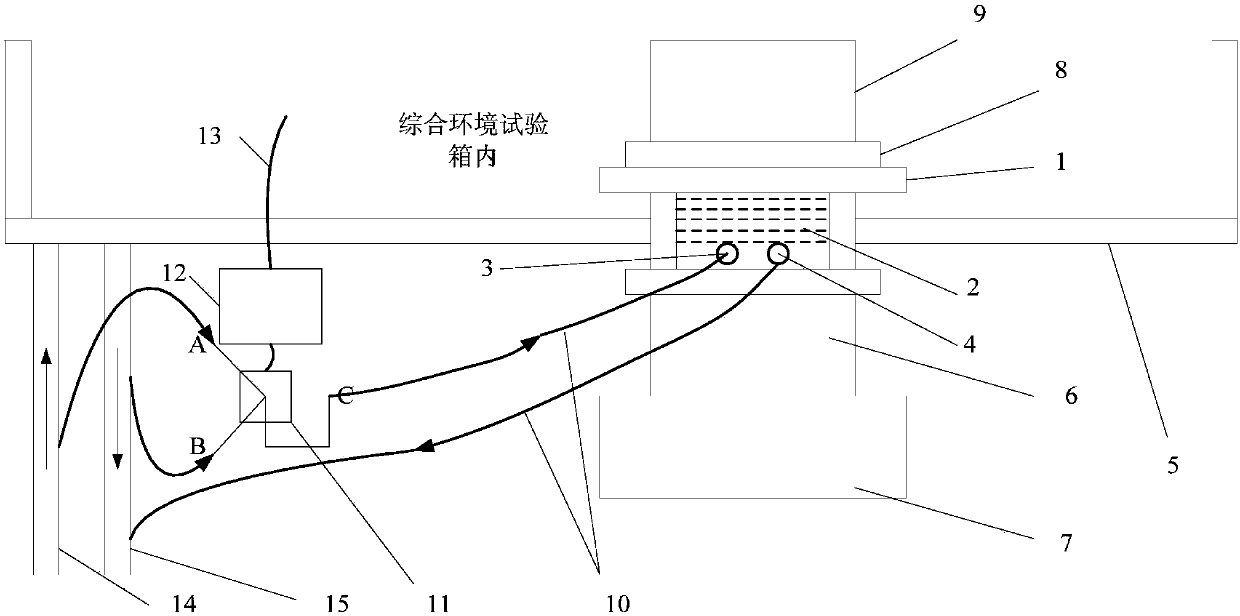

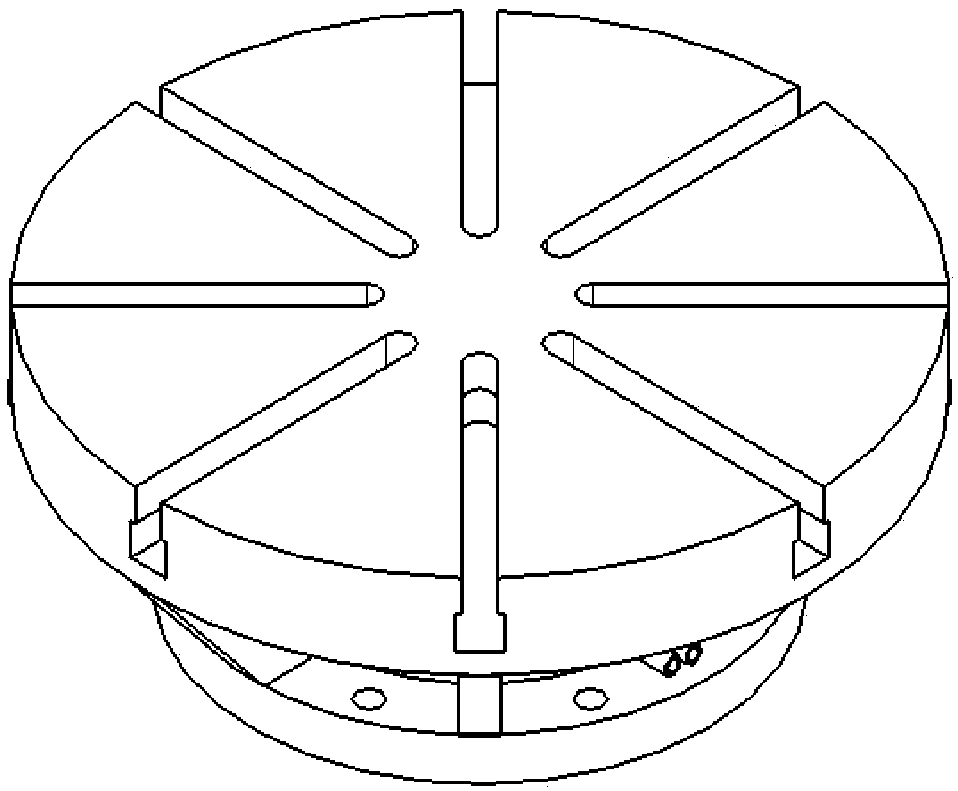

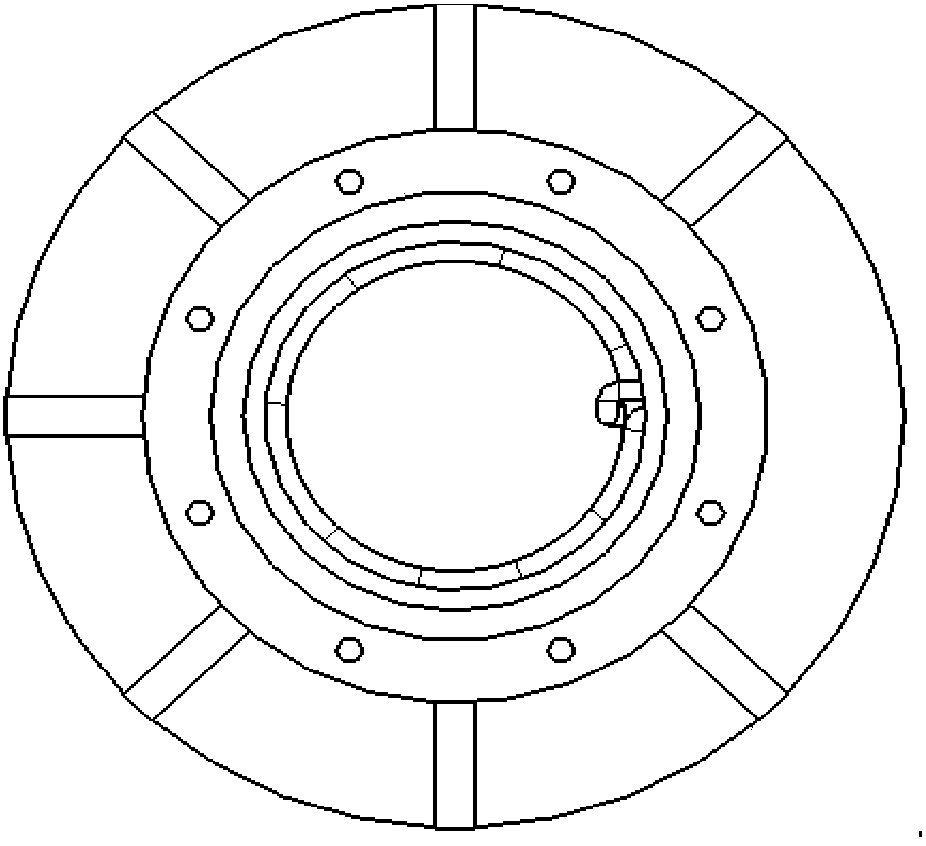

[0034] The present invention as figure 1 As shown, it includes an adapter 1, an embedded water channel 2, a solenoid valve 11, a controller 12, and a temperature sensor 13. The center of the lower end surface of the adapter 1 has a round hole to install the embedded water channel 2, and the embedded water channel inlet and outlet 3, 4 Pass through the side wall of the lower part of the adapter 1, the water inlet 3 of the embedded water channel is connected to the outlet C of the solenoid valve 11 through the hose 10, and the inlets A and B of the solenoid valve 11 are respectively connected to the water supply pipeline 14 and the return pipe of the test chamber Road 15, the embedded water outlet 4 is connected to the return water pipeline 15 of the test chamber through the hose 10, the temperature sensor 13 is installed in the test chamber, the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com