Water faucet lubricating device for well drilling

A faucet and drilling technology, applied in the direction of engine lubrication, lubricating parts, engine components, etc., can solve the problems of complex structure, high labor intensity and high difficulty of the faucet, achieve significant economic and social benefits, reduce labor intensity, use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

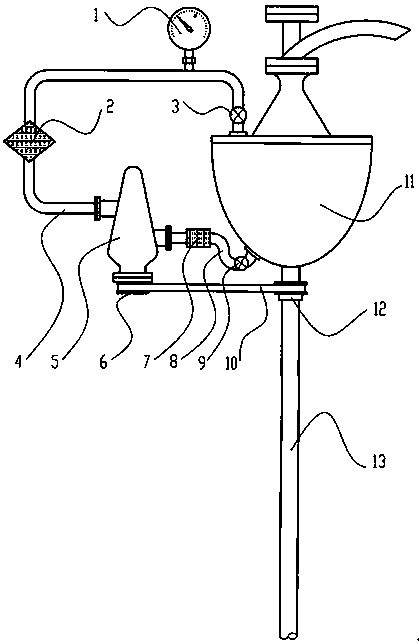

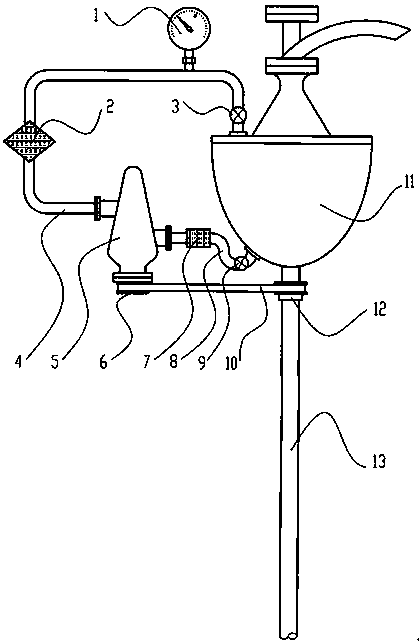

[0010] Attached below figure 1 Examples of the present invention will be described.

[0011] Depend on figure 1 It can be seen that the embodiment of the present invention includes a pressure gauge 1, an oil injection filter 2, an oil inlet valve 3, an oil injection pipe 4, an oil injection pump 5, a driven pulley 6, an oil return filter 7, an oil discharge pipe 8, and an oil discharge valve 9. Belt 10, faucet 11, driving pulley 12, rotating pipe 13, rotating pipe 13 passes through the middle of the water faucet 11, the rotating pipe 13 rotates during drilling, the faucet 11 does not rotate, and the upper end of the faucet 11 has an oil inlet. The oil port communicates with the inside of the faucet 11. There is an oil outlet at the bottom of the faucet 11. The lubricating oil added to the oil inlet can flow from the oil outlet. The inlet end of the oil injection pump 5 and one end of the oil discharge pipe 8 The other end of the oil discharge pipe 8 is connected to the oil o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com