Fabricated concrete cooling tower and construction method

A cooling tower and concrete technology, which is applied in building construction, construction, refrigeration plants, etc., can solve problems such as difficult construction and increased labor costs, and achieve the effects of reducing weight, reducing construction difficulty, and reducing the thickness of the upper layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

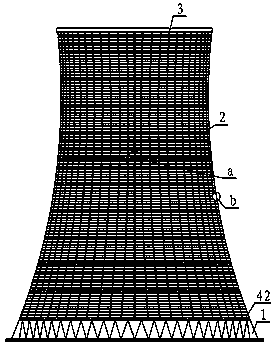

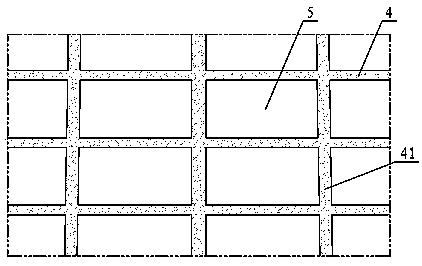

[0043] A concrete cooling tower shell, which consists of: a foundation 1, the upper part of the foundation is connected to the tower wall 2, the upper part of the tower wall is connected to the top hoop 3, the tower wall adopts an assembled structure, and the assembly The stressed member of the formula structure includes a horizontal concrete beam 4 and a hyperbolic concrete column 41 connected with the horizontal concrete beam, and the hyperbolic concrete column is a bottom-up cast-in-place concrete column in the shape of a hyperbolic generatrix A group of prefabricated slabs 5 are sequentially embedded in the stress-bearing members as the height of the cast-in-place concrete column rises, and finally form the cooling tower shell; The horizontal bottom beam 42 is poured, and the hyperbolic concrete column 41 is cast in-situ at the transverse connection position between the prefabricated slabs. The horizontal concrete beam 4 is cast in-situ at the connection position in the he...

Embodiment 2

[0045]In the concrete cooling tower shell described in Embodiment 1, the connection position of the prefabricated slab has an installation assistance mechanism, and the described installation assistance mechanism is equipped with a shear connecting plate 6 and / or a sinker on the edge of the prefabricated slab respectively. The head steel plate 61 is welded or threaded between the shear connecting plates of adjacent prefabricated panels; or the countersunk steel plates of the prefabricated panels on both sides are connected through the shear connecting plates;

[0046] Alternatively, countersunk steel plates or shear connecting pipes are respectively installed on the edge of the prefabricated slab, and the countersunk steel plate of the prefabricated slab on one side is connected to the shear connecting pipe of the prefabricated slab on the other side.

Embodiment 3

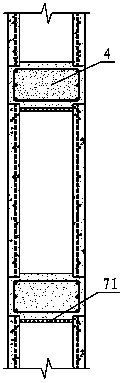

[0048] In the concrete cooling tower shell described in embodiment 1 or 2, there is a pouring channel 7 in the described prefabricated slab, and the horizontal distance between the described pouring channels in the vertical position is 200-800mm; the described pouring channel The upper part has a pouring cover plate 71, and the pouring cover plate is 30-80mm away from the edge of the arc-shaped prefabricated plate. The channel height is 25-75mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com