Longitudinal shear reinforcement and precast slab separated laminated slab composite beam

A technology of shear-resistant steel bars and prefabricated slabs, which is applied to floors, building components, buildings, etc., can solve the problems of inconvenient transportation of prefabricated slabs, inconvenient fixing and positioning of steel bars, and easy collision of beard bars, etc., to achieve reasonable force, simple structure, The effect of shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

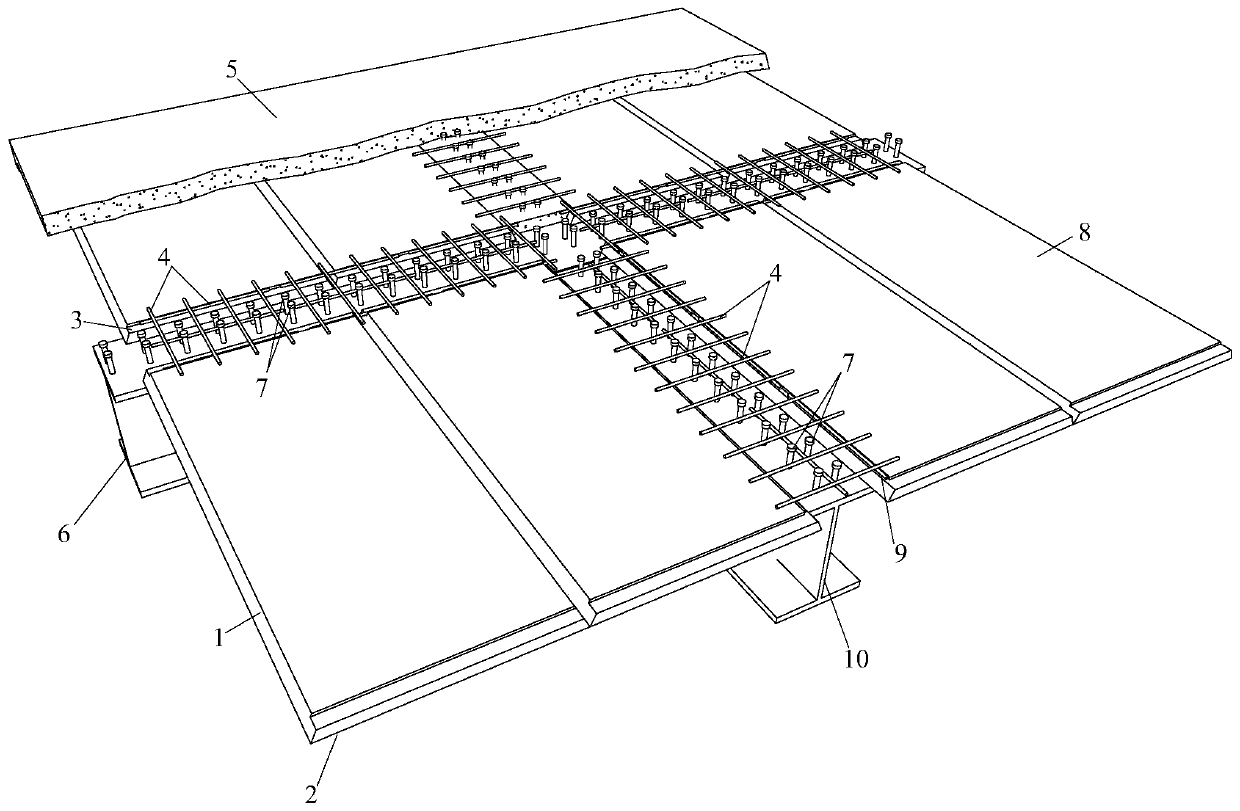

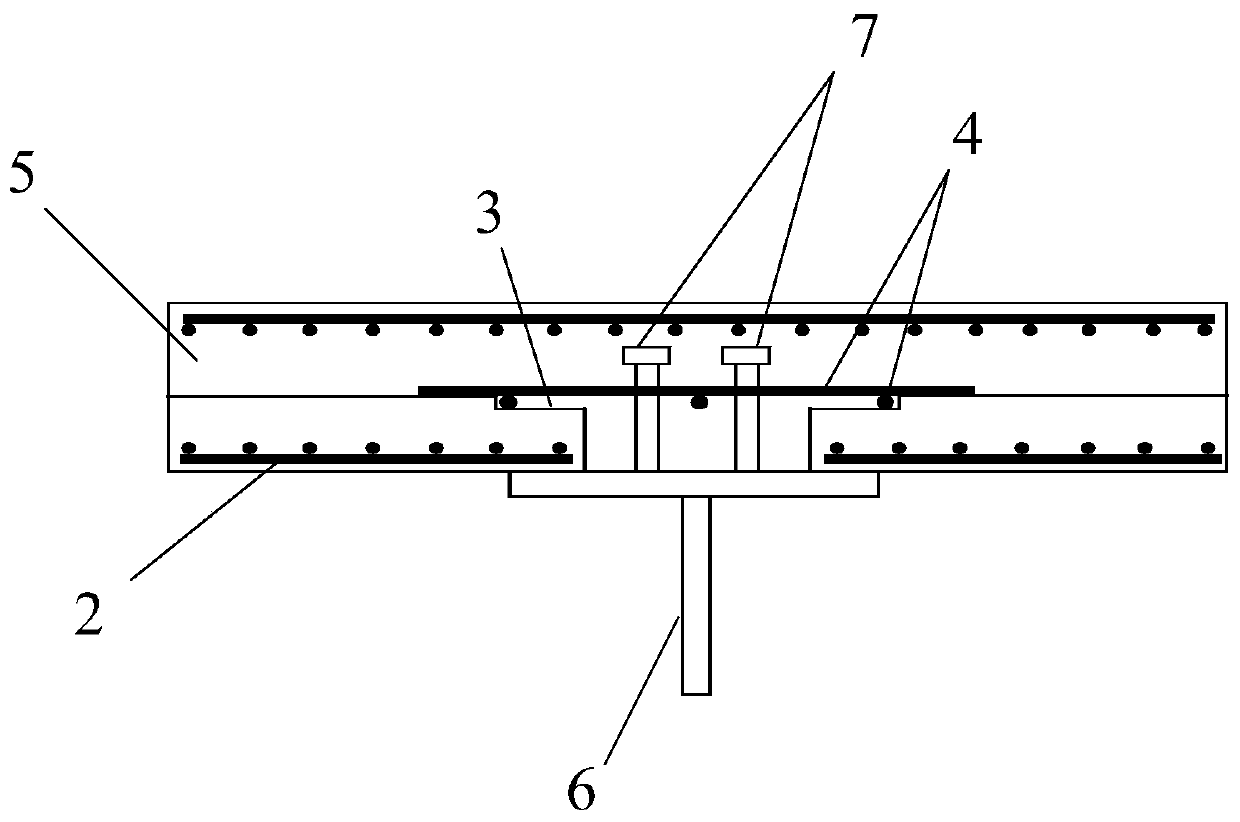

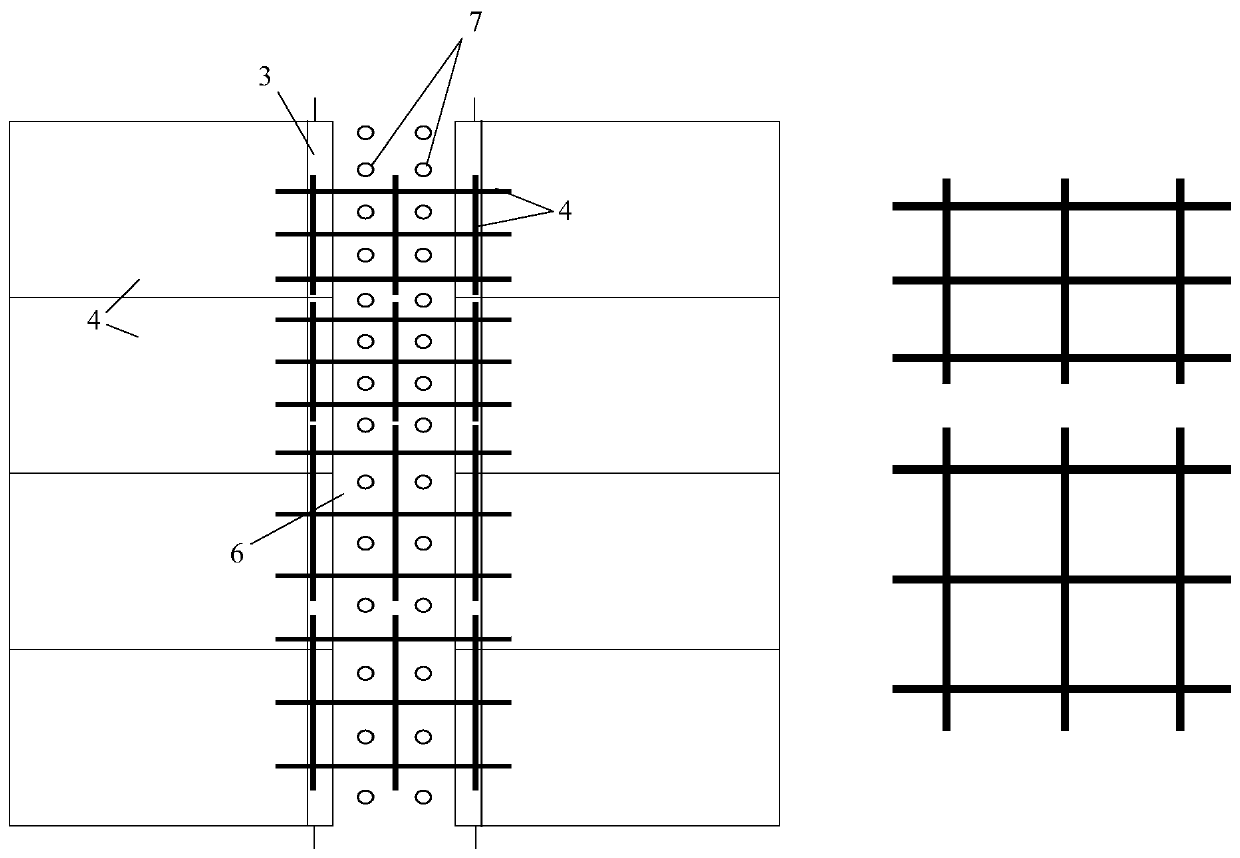

[0034] Below in conjunction with accompanying drawing, structure of the present invention, construction process are described further.

[0035] Such as figure 1As shown, the laminated slab composite beam separated from the longitudinal shear reinforcement and the prefabricated slab of the present invention comprises a concrete prefabricated slab (1) with an open end platform, an additional reinforcement mesh unit (4) in the platform and a post-cast concrete layer (5) , wherein the two ends of the prefabricated slab (1) cancel the beard bars, and the longitudinal steel bars (2) in the slab are flush with the plate ends of the prefabricated slab (1). When the factory is making prefabricated slab components, a stepped platform (3) is pre-opened at the end of the slab, and the end of the platform-opened concrete prefabricated slab (1) rests on the upper flange of the steel beam (6). When the prefabricated panel is installed, it will not conflict with the studs (7) on the upper fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com