Light control alignment polyimide liquid crystal alignment membrane as well as preparation method and application thereof

A polyimide, light-controlled orientation technology, used in optics, nonlinear optics, instruments, etc., to achieve the effect of uniform orientation of liquid crystal cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

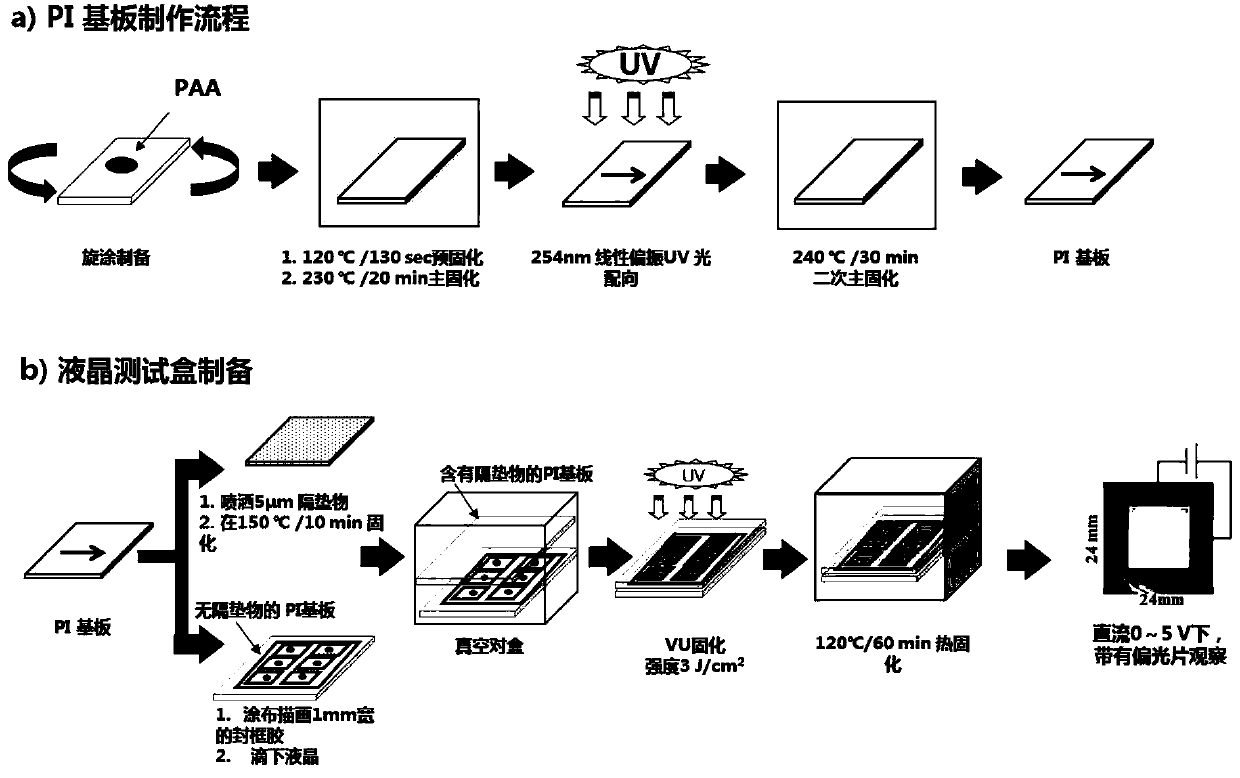

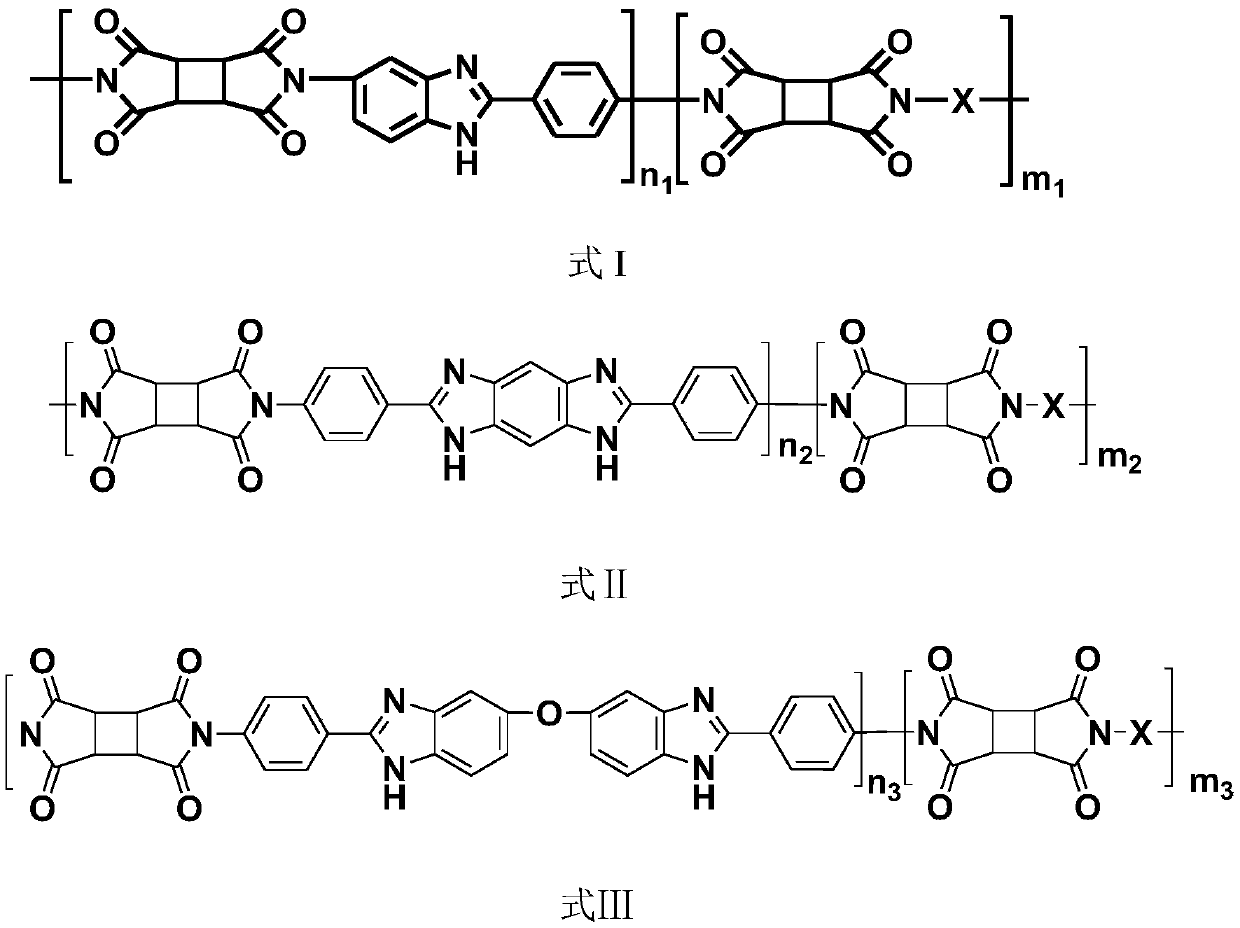

[0064] Add 197.1g N-methylpyrrolidone to a 1000mL three-necked flask equipped with a nitrogen inlet, water separator and thermometer, then add 11.365g (50mmol) 4APBI (2,3,5-APBI) and 12.916g (50mmol) 1 , 3-bis(4-aminophenoxy)propane (BAPE), stirred and dissolved to form a homogeneous solution; 19.32g (98.5mmol) CBDA and 50g N-methylpyrrolidone solvent were added to the above solution, and the reaction was stirred (25°C ) 4h to obtain a viscous PAA-1 polyamic acid solution with a solid content of 15wt%. Take 150g of the above solution, add 150g of NMP, 75g of BC and various additives (2,3,4-trihydroxybenzophenone as a crosslinking agent, hexamethylsilane as a surface adhesion promoter), stir for 15min, and adjust the viscosity to 56 mPa·s, press-filter to obtain a photo-alignment polyimide liquid crystal alignment liquid with a solid content of 6%, and store it in a -15°C refrigerator. Such as figure 1 As shown in a), take about 3ml of the solution, drop it on the glass subst...

Embodiment 2

[0072] Add 156.7g N-methylpyrrolidone in a 1000mL three-neck flask equipped with a nitrogen inlet, water separator and thermometer, then add 11.365g (50mmol) 4APBI and stir to dissolve to form a homogeneous solution; add 19.32g (98.5 mmol) CBDA and 50g N-methylpyrrolidone solvent, stirred and reacted (25°C) for 12h, then added 14.615g (50mmol) 1,3-bis(4-aminophenoxy)benzene (1,3, 4APB), 50g of N-methylpyrrolidone solvent, stirred and reacted (25°C) for 12h to obtain a viscous PAA-2 polyamic acid solution with a solid content of 15wt%. Take 150g of the above solution, add 150g of NMP, 75g of BC and various additives (2,3,4-trihydroxybenzophenone as a crosslinking agent, hexamethylsilane as a surface adhesion promoter), stir for 15min, and adjust the viscosity to 54 mPa·s, press-filter to obtain a photo-alignment polyimide liquid crystal alignment liquid with a solid content of 6%, and store it in a -15°C refrigerator. Such as figure 1 As shown in a), take about 3ml of the sol...

Embodiment 3

[0080] Add 229.1g N-methylpyrrolidone in a 1000mL three-neck flask equipped with nitrogen inlet, water separator and thermometer, then add 17.017g (50mmol) diamine compound (R 1 connected to the para-position, R 2 connected to the para-position) and 12.916g (50mmol) 1,3-bis(4-aminophenoxy)propane (BAPE), stirring and dissolving to form a homogeneous solution; add 19.32g (98.5mmol) CBDA and 50g N-methylpyrrolidone solvent, stirred and reacted (25° C.) for 4 hours to obtain a viscous PAA-1 polyamic acid solution with a solid content of 15 wt%. Take 150g of the above solution, add 150g of NMP, 75g of BC and various additives (2,3,4-trihydroxybenzophenone as a crosslinking agent, hexamethylsilane as a surface adhesion promoter), stir for 15min, and adjust the viscosity to 58 mPas, press-filter to obtain a photo-alignment polyimide liquid crystal alignment liquid with a solid content of 6%, and store it in a -15°C refrigerator. Such as figure 1 As shown in a), take about 3ml of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

| Pretilt | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com