High-speed glue-free tail sealing device and working method thereof

A working method and glue sealing technology, which is applied in transportation and packaging, winding strips, thin material handling, etc., can solve problems that affect processing efficiency, consume a lot of time, and consume a large amount of glue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

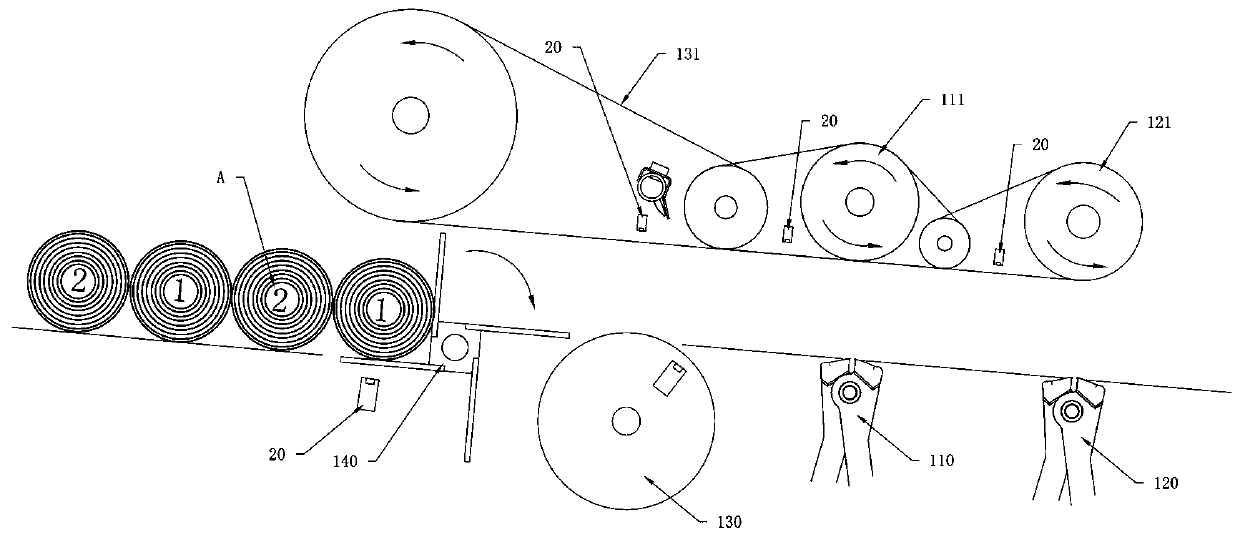

[0024] See attached figure 1 to attach Figure 7 As shown, in this embodiment, a high-speed glue-free tail-sealing device, the tail-sealing device sequentially includes a cross turning plate 140, a tail-seeking orientation mechanism 130, a first tail-sealing unit 110 and In the second tail-sealing unit 120 , the cross-turning plate 140 is used to turn over several rolls A one by one and transport them to the tail-seeking orienting mechanism 130 .

[0025] In this technical field, the tail-seeking orienting mechanism 130 belongs to common knowledge. You can refer to the tail-seeking orienting mechanism 130 disclosed in the publication number CN1137259C and CN104755400A. Those skilled in the art can choose a suitable tail-seeking orientation according to actual needs Agency 130. And the tail-seeking orientation mechanism 130 of the present embodiment includes directional rollers, directional film base belt 131, air blowing pipe and paper tail electric eye, wherein, directional...

Embodiment 2

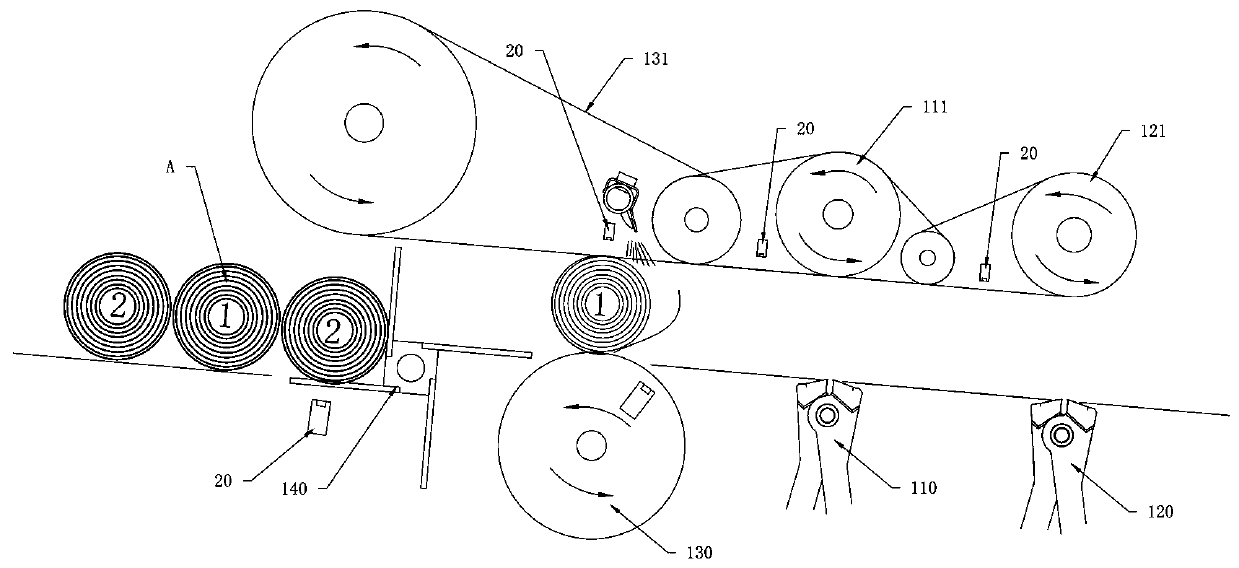

[0040] Refer to attached Figure 8 to attach Figure 13 As shown, in this embodiment, the difference compared with Embodiment 1 is that a transition section 150 is provided between the tail-seeking and orientation mechanism 130 and the first tail-sealing unit 110, wherein the transition section 150 is used for buffering At least one reel A processed by the tail-seeking orienting mechanism 130 stays, that is, during the process of rolling the previous reel group to the sealing unit or performing pressing and sealing, the reel A of the next reel group After A is adjusted in place by the tail-seeking orienting mechanism 130 one by one, it can be rolled to the transition section 150 by the tail-seeking orienting mechanism 130 for buffering and staying.

[0041] See attached Figure 13 As shown, in order to facilitate the understanding of those skilled in the art, a single reel A is buffered and stayed in the transition section 150, but for actual production conditions, two or mo...

Embodiment 3

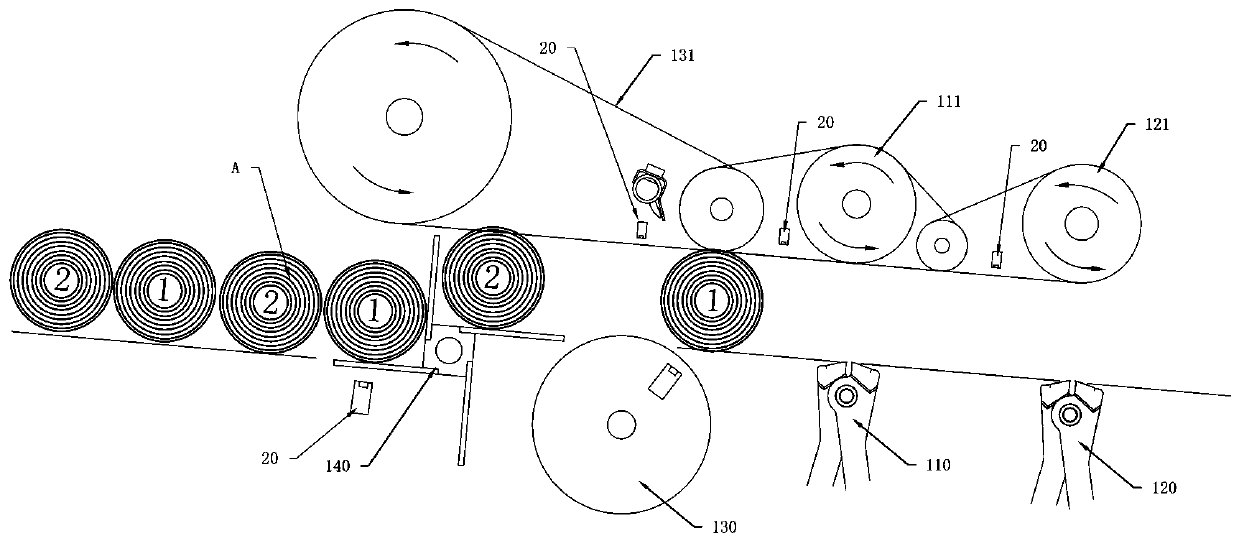

[0045] See attached Figure 15 As shown, in this embodiment, the difference compared with the above embodiment is that this embodiment includes three or more end-sealing units. For ease of understanding, this embodiment describes the three units, The rest of the schemes using more than three are derivative schemes of this embodiment, and no additional details are given here.

[0046] In this embodiment, it is defined that three sealing units are arranged front and back in sequence, which are respectively the first sealing unit 110, the second sealing unit 120 and the third sealing unit 160, and the upper order of each sealing unit is configured The corresponding extruding devices are respectively the first extruding device 111 , the second extruding device 121 and the third extruding device 161 . To this end, by grouping several reels A in groups of three, that is, every three reels A that are continuously fed in are regarded as a group of reels, and by sequentially sending t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com