Wheat warehouse management machine

A technology for managing machines and wheat, applied to agricultural machinery and tools, fruit hanging devices, climate change adaptation, etc., can solve the problems of time-consuming and labor-intensive manual shoveling, falling into grain piles, and low efficiency, so as to improve safety and prevent Mildew, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

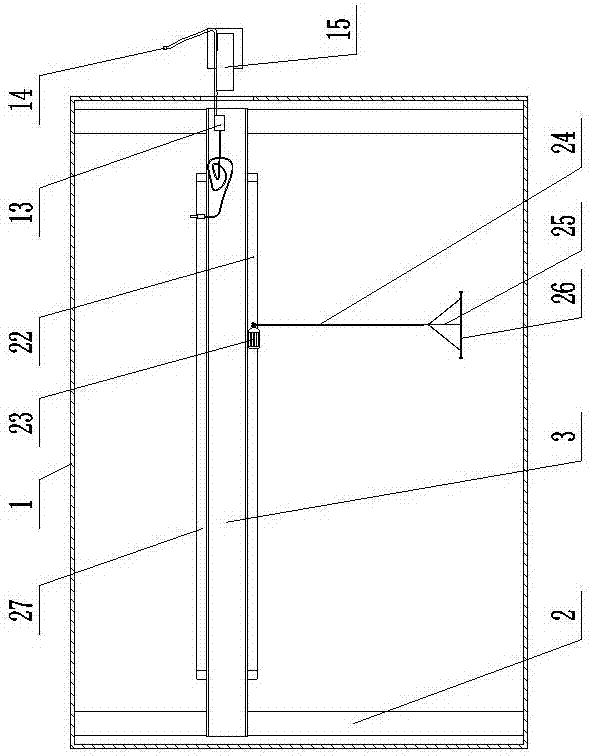

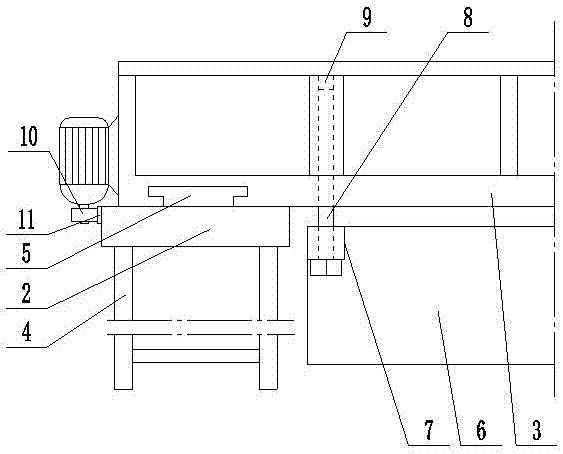

[0033] Such as Figure 1-2 As shown, the wheat storage bin management machine of the present invention includes rails 2 arranged on two opposite sides of the storage bin 1 and a walkway 3 movable between the two rails 2, two opposite sides of the storage bin 1 The sides are respectively buried and fixed with a high-foot long bar frame 4 and each high-foot long bar frame 4 is provided with a T-shaped track 5, and the bottom surface of the end of the walkway 3 is mounted on the T-shaped track 5 with activities, and the walkway 3 passes through the T-shaped track 5. The deceleration reciprocating mechanism reciprocates on the high-foot long bar frame 4.

[0034] A scraper 6 is fixedly installed under the walkway 3 through a height adjustment mechanism;

[0035] The height adjustment mechanism includes a long nut 7 fixedly arranged on both sides of the upper end of the scraper 6 and a long screw 8 whose lower part is fixed in the long nut 7. 6 fixed and height adjustment.

[00...

Embodiment 2

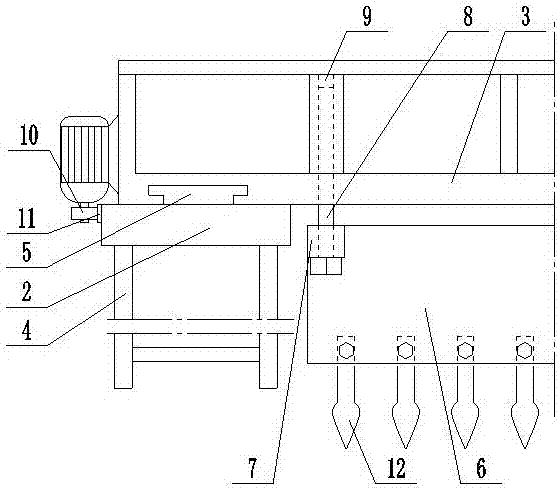

[0047] Such as Figure 3-4 As shown, on the basis of the first embodiment, the lower part of the scraper 6 is fixed with a plurality of plow teeth 12 by bolts, and the lower ends of the plow teeth 12 are bent to one side.

[0048] In this embodiment, on the basis of the first embodiment, through the movement of the aisle 3, the plow teeth 12 under the scraper 6 can be inserted into the grain and move horizontally, so as to realize the work of plane turning in the daily management of the granary.

Embodiment 3

[0050] Such as Figure 5 As shown, on the basis of Embodiment 2, a lifting car 15 is arranged outside the window of the storage bin 1;

[0051] Described elevating car 15 comprises the vehicle frame 16 that bottom is provided with wheel, escalator 17 and lifting column 18, and one end of described escalator 17 is hinged on vehicle frame 16, and vehicle frame 16 bottom surface middle parts are provided with slide rail 19, and lifting column 18 The bottom end of the cylinder body is fixed on the vehicle frame 16, and the end of the piston rod of the lifting column 18 is movably clamped inside the slide rail 19;

[0052] One side of the lift car 15 is provided with a water receiving pipe 20, the lower end of the water receiving pipe 20 communicates with the fire hydrant 14 through a water pipe and its upper end is connected with the water inlet of the fire gun equipment group 13 on the walkway 3 through a water pipe Pass.

[0053] In this embodiment, on the basis of Embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com