An automatic capping device for blood collection tubes

A blood collection tube and automatic technology, applied in the field of medical equipment, can solve the problems of operators' biological hazards, high labor intensity, environmental and biological pollution, etc., and achieve the effects of novel structure design, high work efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described below in conjunction with specific embodiments.

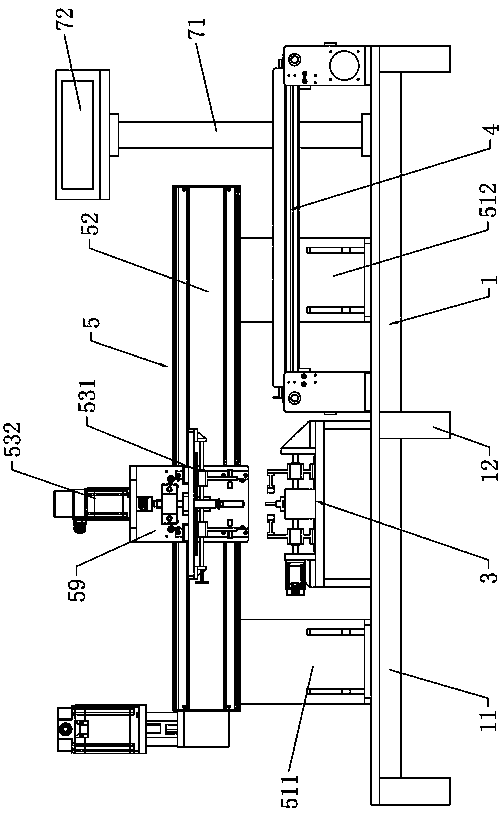

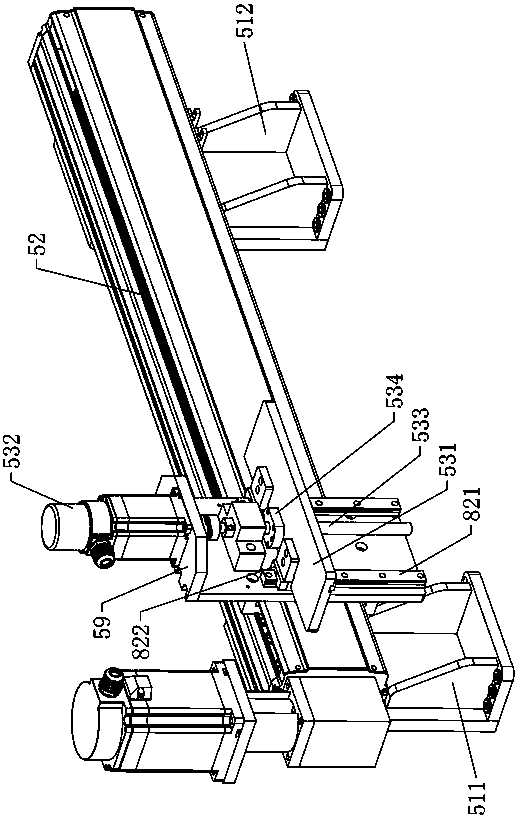

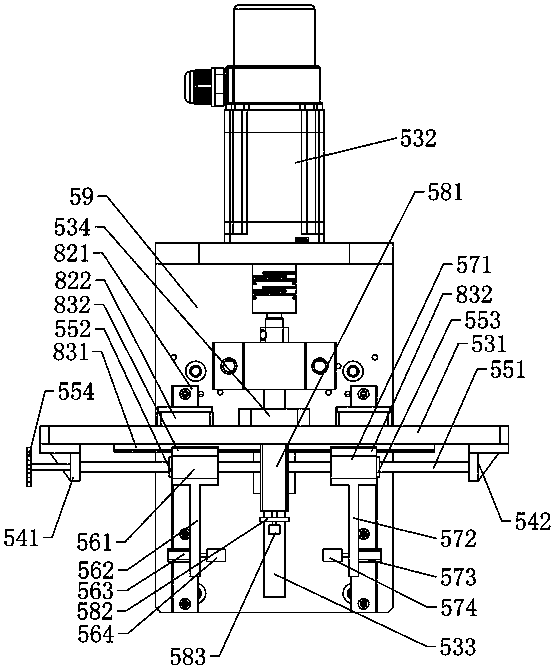

[0066] Such as Figure 1 to Figure 6 As shown, an automatic capping device for blood collection tubes includes a support frame 1. The support frame 1 includes a fixed support plate 11 arranged horizontally and horizontally. The lower end side of the fixed support plate 11 is equipped with uniform The fixed legs 12 distributed at intervals and extending vertically respectively, the upper ends of each fixed leg 12 are respectively screw-mounted on the lower surface of the fixed support plate 11; Tube cap automatic loading assembly 2, blood collection tube placing and clamping assembly 3, blood collection tube automatic conveying assembly 4, the upper end side of blood collection tube placing and clamping assembly 3 is equipped with an automatic transfer capping assembly 5.

[0067] Wherein, the pipe cap automatic feeding assembly 2 includes a feeding installation frame 21 screwed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com