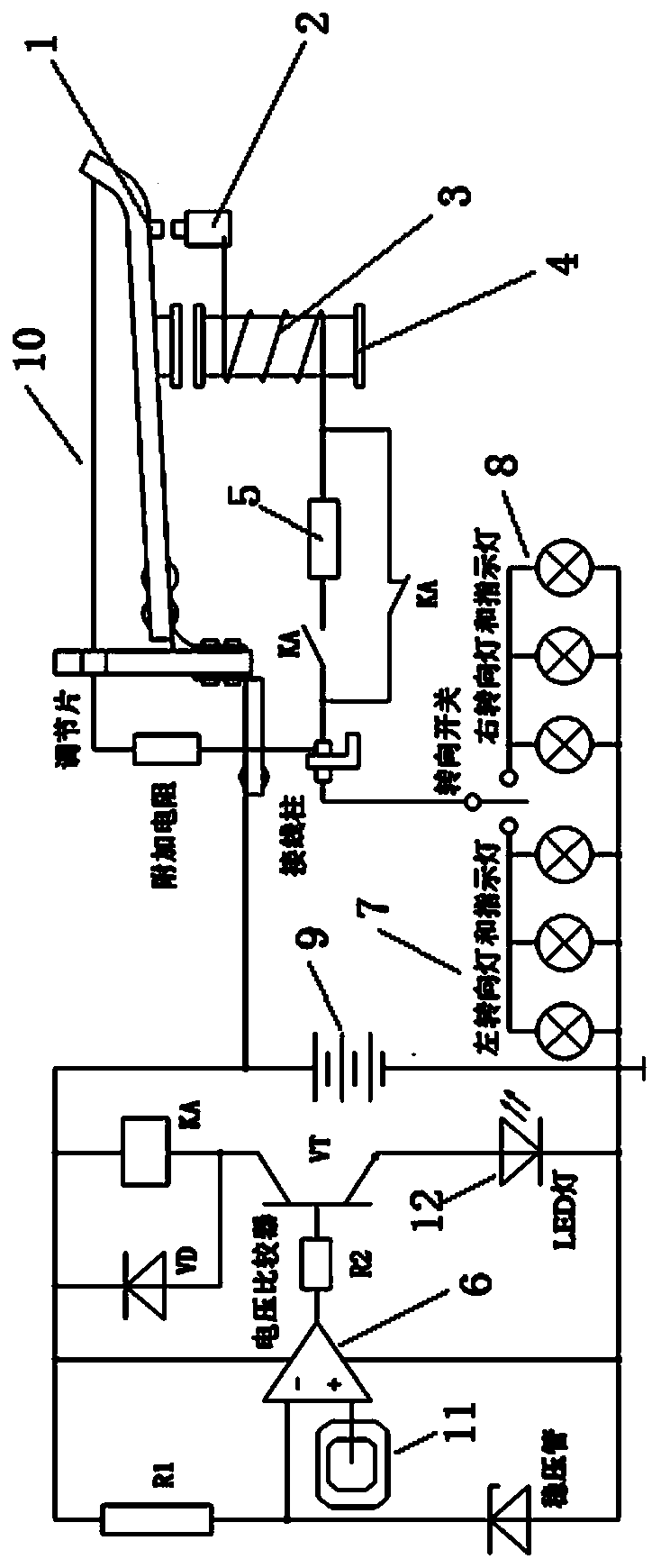

Dual-gear-automatic-switching heating-wire flasher circuit

An automatic switching, heating wire technology, applied in optical signals, signal devices, transportation and packaging, etc., can solve problems such as affecting the function of vehicle lights, changing the flashing frequency of heating wire flashers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] When the vehicle is running and encounters rain, the output voltage of the rain sensor increases with the increase of rainfall received by the detection end of the rain sensor located on the outer surface of the vehicle body. When the first input end of the voltage comparator and the second When the voltage difference at the input terminal is greater than the threshold value, the voltage comparator outputs a high level to turn on the triode VT to energize the main relay KA, so that the normally open contact is closed and the normally closed contact is disconnected, so that the frequency high-speed gear circuit The accelerating resistor is connected in series with the electromagnet coil to reduce the electromagnet current to reduce the suction force of the electromagnet and reduce the cooling time of the heating wire required for the heating wire to pull the moving contact away from the fixed contact, so as to speed up the switching frequency of the strobe switch , so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com