Precise and environmentally-friendly drilling method for multi-angle building wall face

A drilling method and multi-angle technology, applied in the direction of work accessories, manufacturing tools, stone processing tools, etc., can solve the problems of unstable support, poor drilling accuracy, and the inability of workers to directly obtain drilling information, etc., to achieve convenient transportation, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

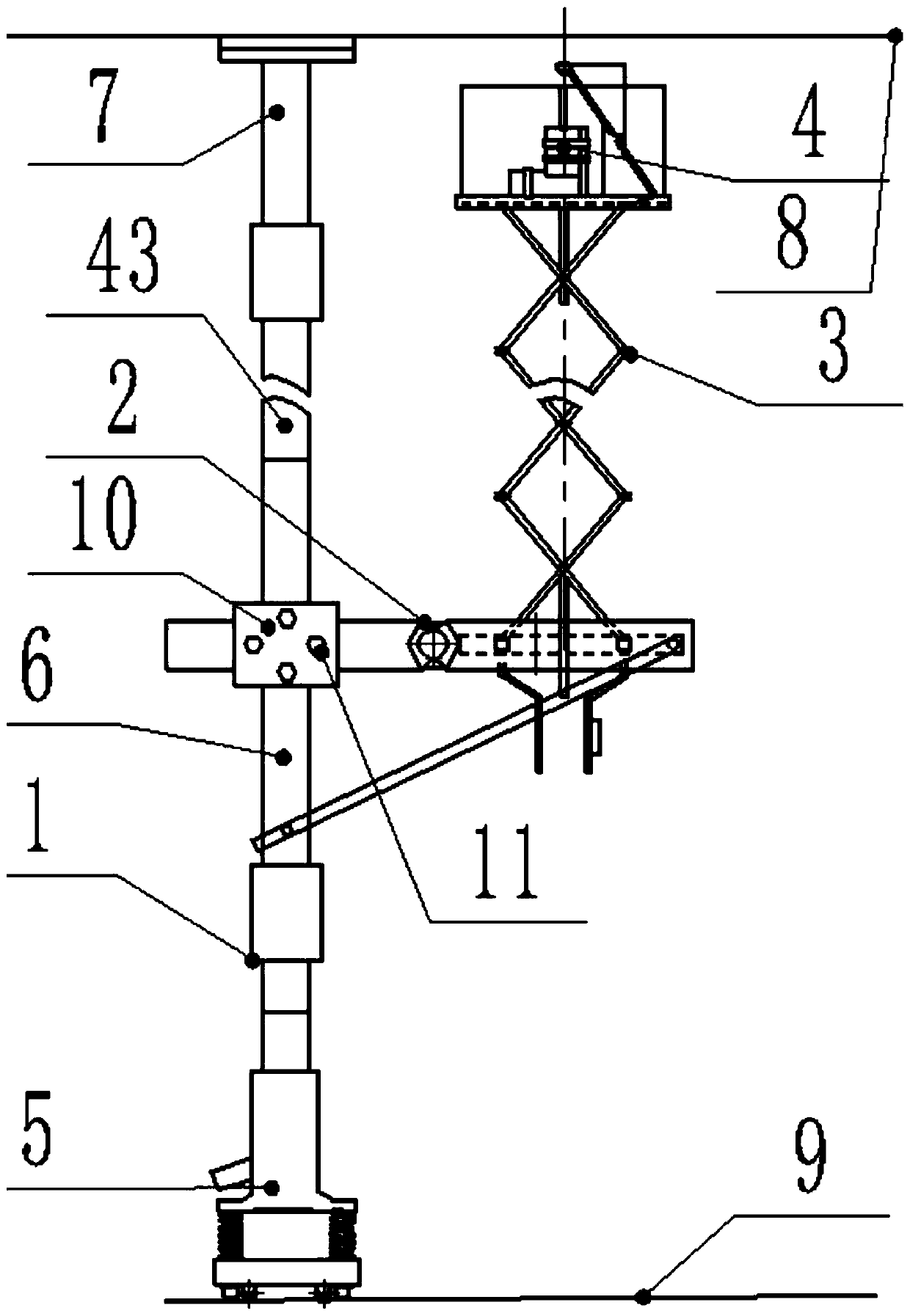

[0043] like Figure 1-6 Shown, a kind of drilling method of the present invention realizes the multi-angle wall of accurate environmental protection building, it is characterized in that, comprises steps:

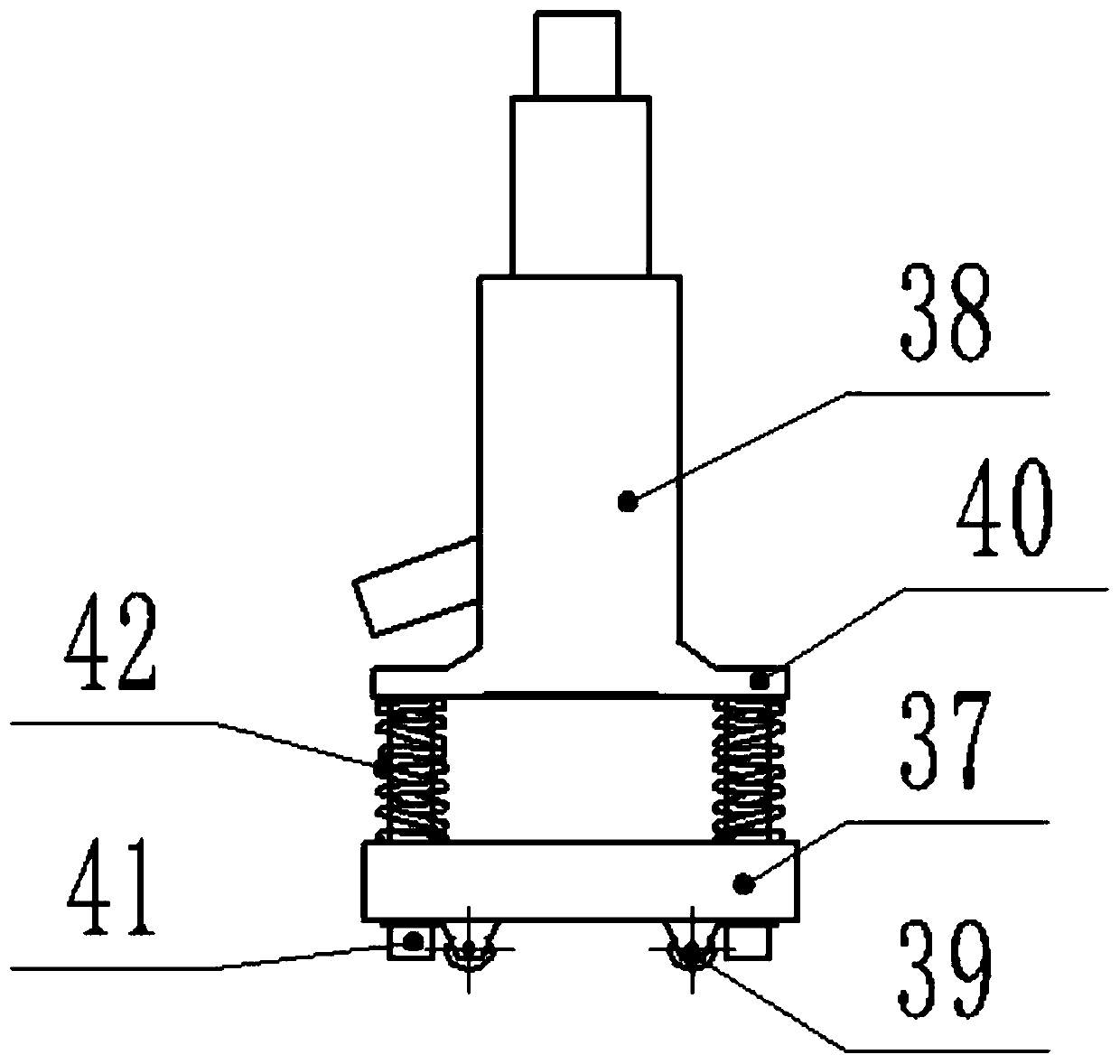

[0044] Step 1. Determine the drilling position on the building wall, and set the telescopic hydraulic support column 1. The telescopic hydraulic support column 1 includes a hydraulic support base 5, a middle support column 6 and a support top seat 7, a hydraulic support base 5, a middle support The column 6 and the support top seat 7 are sequentially connected and assembled from bottom to top, and initially supported between the top wall 8 and the floor 9 of the building;

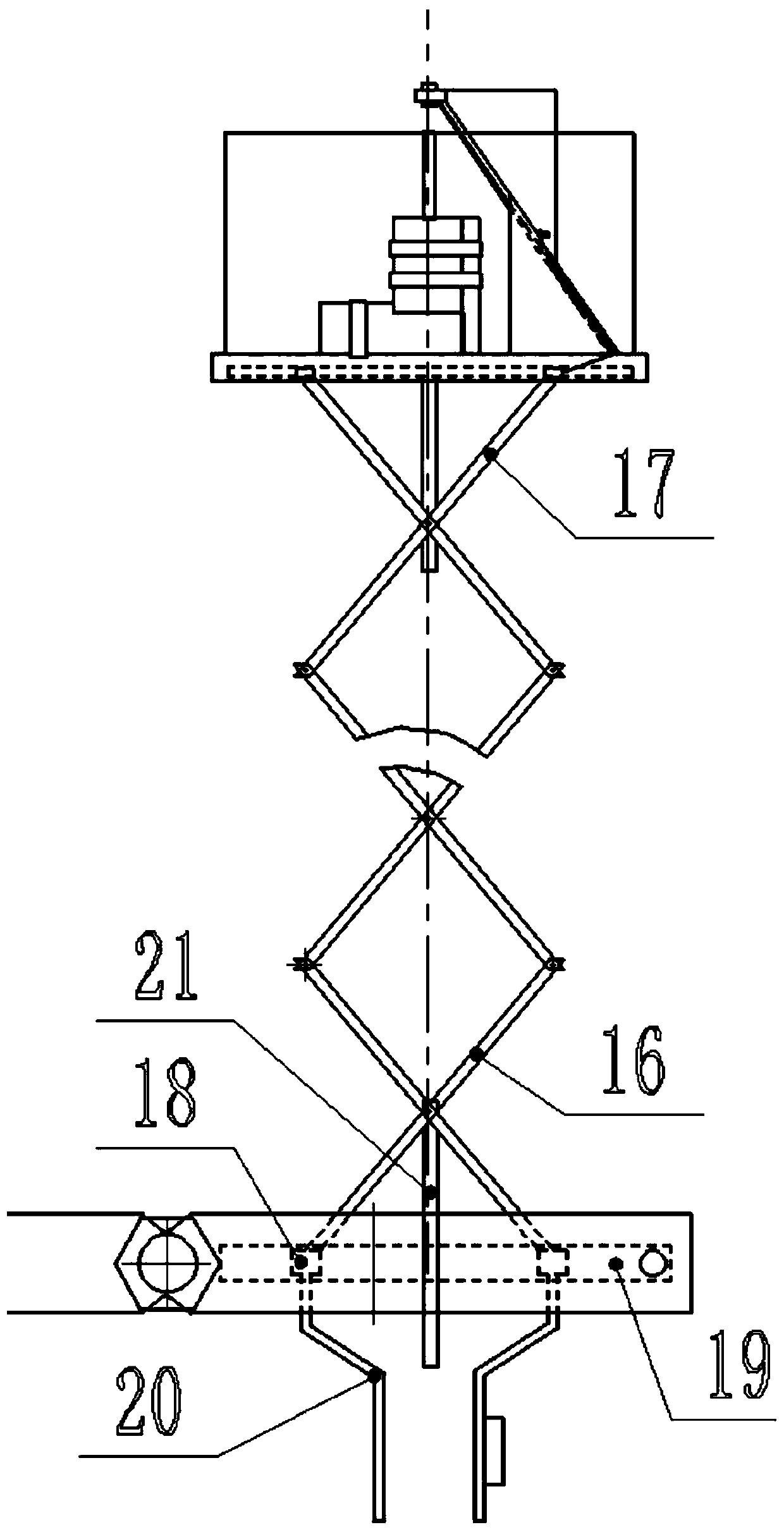

[0045] Step 2. A sliding vertical and horizontal connection block 10 is provided on the middle support column 6, and a longitudinal adjustment hole and a horizontal adjustment hole are provided on the sliding vertical and horizontal connection block 10. The longitudinal adjustment hole of the sliding ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com