Full-automatic steel rail accurate grinding machine

A fine grinding machine, fully automatic technology, applied in the direction of grinding machine parts, grinding machines, grinding/polishing equipment, etc., can solve the problems of heavy grinding workload, high labor intensity, long grinding and maintenance time, etc., and achieve high grinding speed Fast, easy on-site portability, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

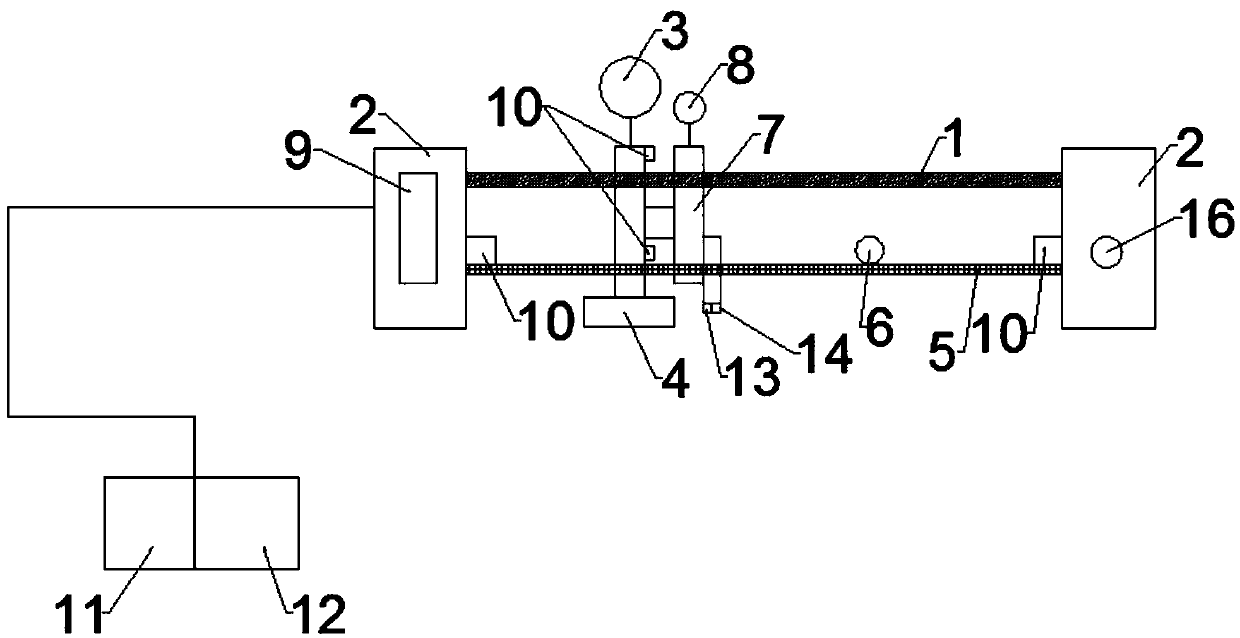

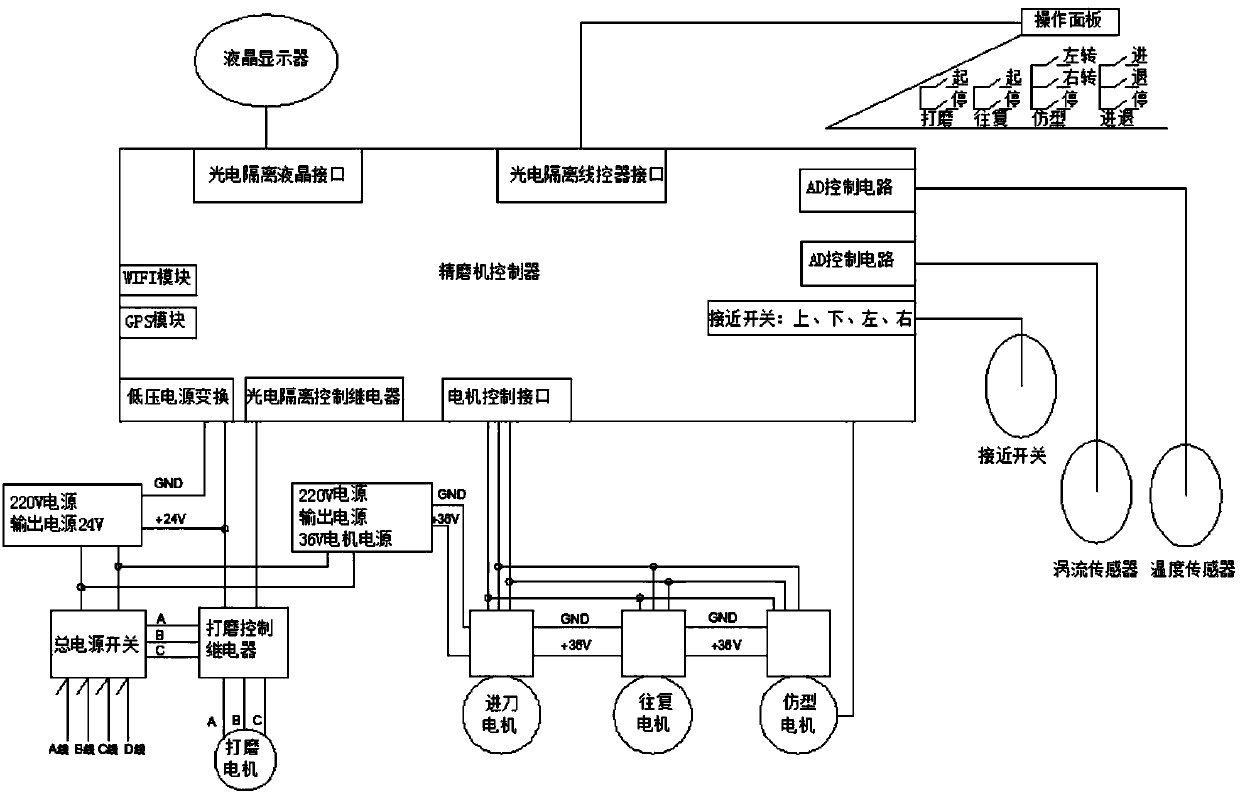

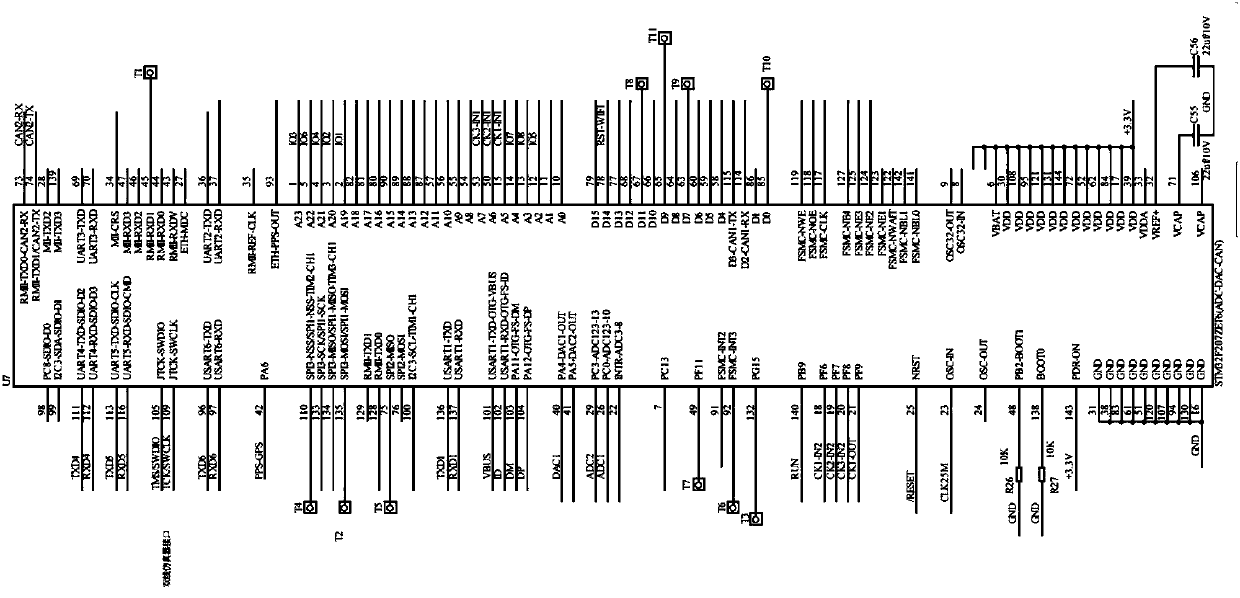

[0048] like Figure 1-10As shown, a fully automatic rail fine grinding machine includes a fixed frame and a grinding device arranged on the fixed frame, and is characterized in that the fixed frame includes a fixed horizontal frame 1 and fixed vertical frames arranged at both ends of the fixed horizontal frame 1 2. The grinding device includes a grinding motor 3 slidably connected to the fixed horizontal frame 1. The rotating shaft of the grinding motor 3 is connected with a grinding wheel 4. A moving belt 5 that drives the grinding wheel 4 to move left and right is arranged between the two fixed vertical frames 2. The moving belt 5 moves left and right through the reciprocating motor 6, and the grinding wheel 4 is also connected with the feed motor 8 that controls the grinding wheel 4 to move up and down through the deceleration mobile transmission device 7. The fixed vertical frame 2 is provided with a control grinding motor 3, a feed The control processor 9 of motor 8 and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com