Automatic food detecting and processing system and method for 3D food printer

An automatic detection and processing system technology, applied in the direction of food science, food forming, application, etc., can solve the problems of not being able to fully supervise the market, not being able to obtain food marketing and sales data and data analysis methods, and not involving the level of supervision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] refer to Figure 1-6 , Figure 9 , Figure 11-13 shown.

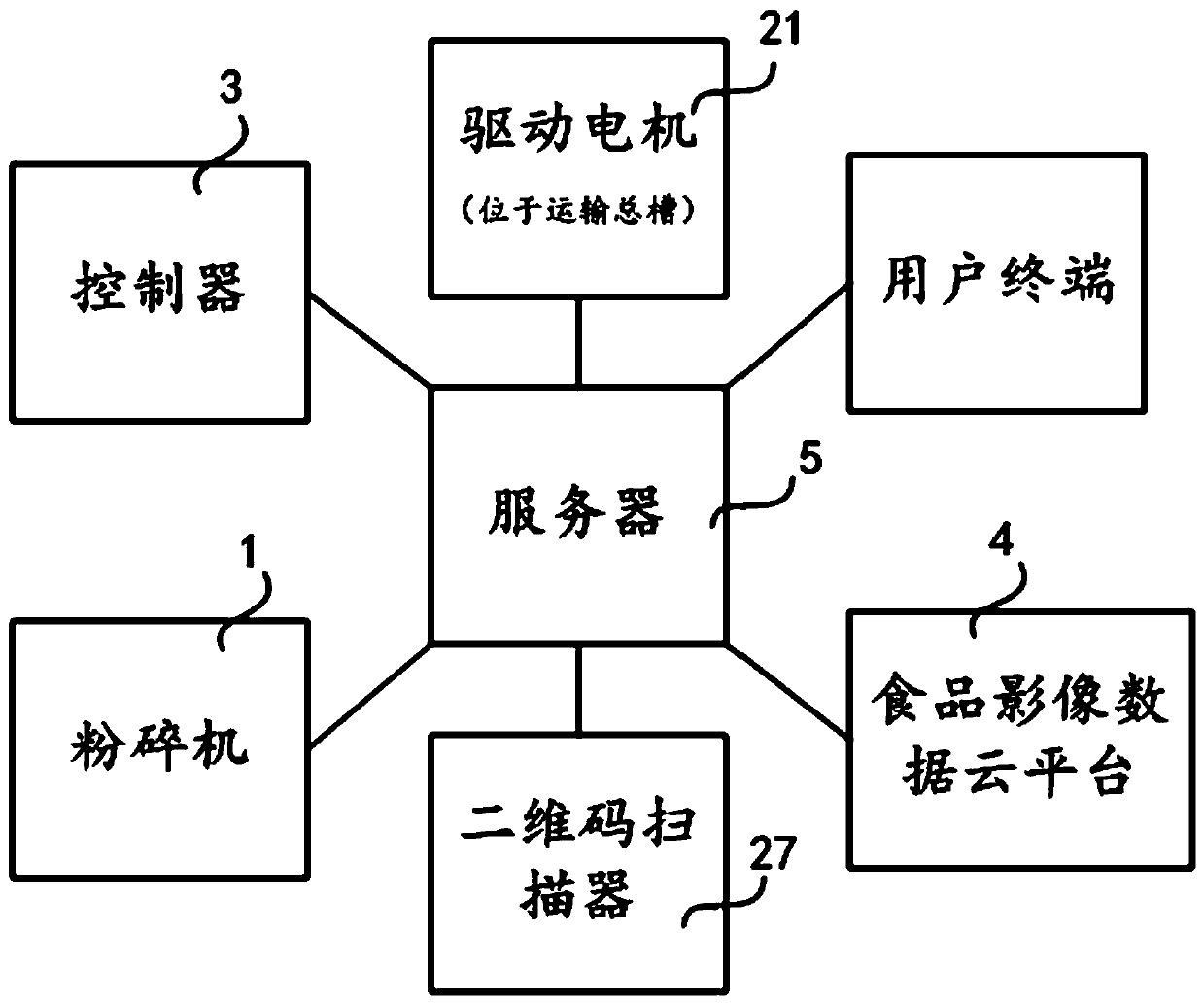

[0060] Specifically, this embodiment provides an automatic food detection and processing system for a 3D food printer 10 , including a food processing device 1 , a food transportation device 2 , a controller 3 , a food image data cloud platform 4 and a server 5 .

[0061]The food processing device 1 includes a 3D food printer 10, a laser printing mechanism 11, a food packaging mechanism 12 and a two-dimensional code generation module 13, and the 3D food printers 10 are evenly arranged and stored in the internal position of the food processing plant; the laser printing mechanism 11 includes a laser generator 110 , the first camera 111, the food recognition module 112 and the food positioning module 113, the laser generator 110 is arranged at the internal position of the printing space of the 3D food printer 10 and is connected with the first camera 111, the food recognition module 112 and the food positioning mo...

Embodiment 2

[0080] refer to Figure 1-6 , Figure 9 , Figure 11-14 shown.

[0081] Specifically, this embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, the delivery motor 242 is connected with an electric fixing clip 244, and the electric fixing clip 244 is arranged at the position of the moving track 243 on the inner wall of the delivery channel 240 and It is fixed with the food packaging bag, and is connected with the controller 3 and the delivery motor 242 respectively.

[0082] As a preferred mode of the present invention, the mechanical arm 126 is provided with a third rotating shaft 126-1 and an electric heating block 126-2, and the third rotating shaft 126-1 is arranged at the side position of the front end of the mechanical arm 126 and is connected with the mechanical arm respectively. 126, the controller 3 and the electric heating block 126-2 are connected; the electric heating block 126-2 is arranged at the front end of the third ro...

Embodiment 3

[0102] refer to Figure 1-5 , Figure 7-8 , Figure 10 shown.

[0103] Specifically, this embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, the food transportation device 2 also includes a two-dimensional code scanner 27 and a storage case 28, and the two-dimensional code scanner 27 is arranged on The inner wall of the printing space of the 3D food printer 10 is wirelessly connected to the server 5; the storage case 28 is placed in the connection area between the transport branch tank 20 and the transport main tank 26, and a storage bin is arranged above the storage case 28.

[0104] As a preferred mode of the present invention, the food transportation device 2 also includes a rejecting mechanism 29, and the rejecting mechanism 29 includes a push housing 290, a telescopic motor 291, a connecting rod 292, a spring 293 and a push block 294, and the push housing 290 is arranged on the transport The branch tank 20 is connected to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com