High-clearance corn male removing machine

A technology of high ground clearance and detasseling machine is applied in the field of agricultural engineering, which can solve the problems of corn plant damage, high production cost, high planting density, etc., and achieve the effects of reducing production cost, convenient maintenance and replacement, and reducing power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

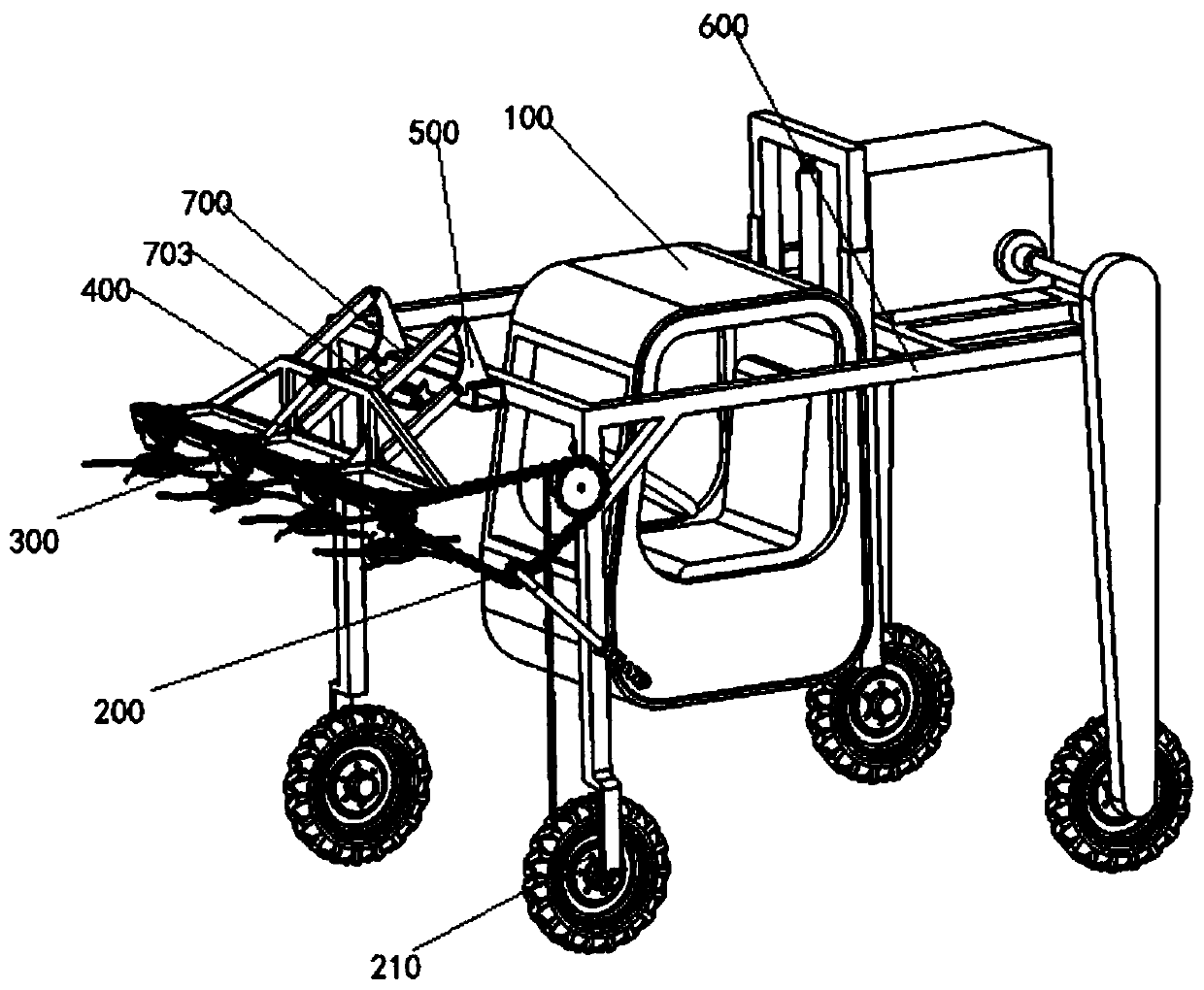

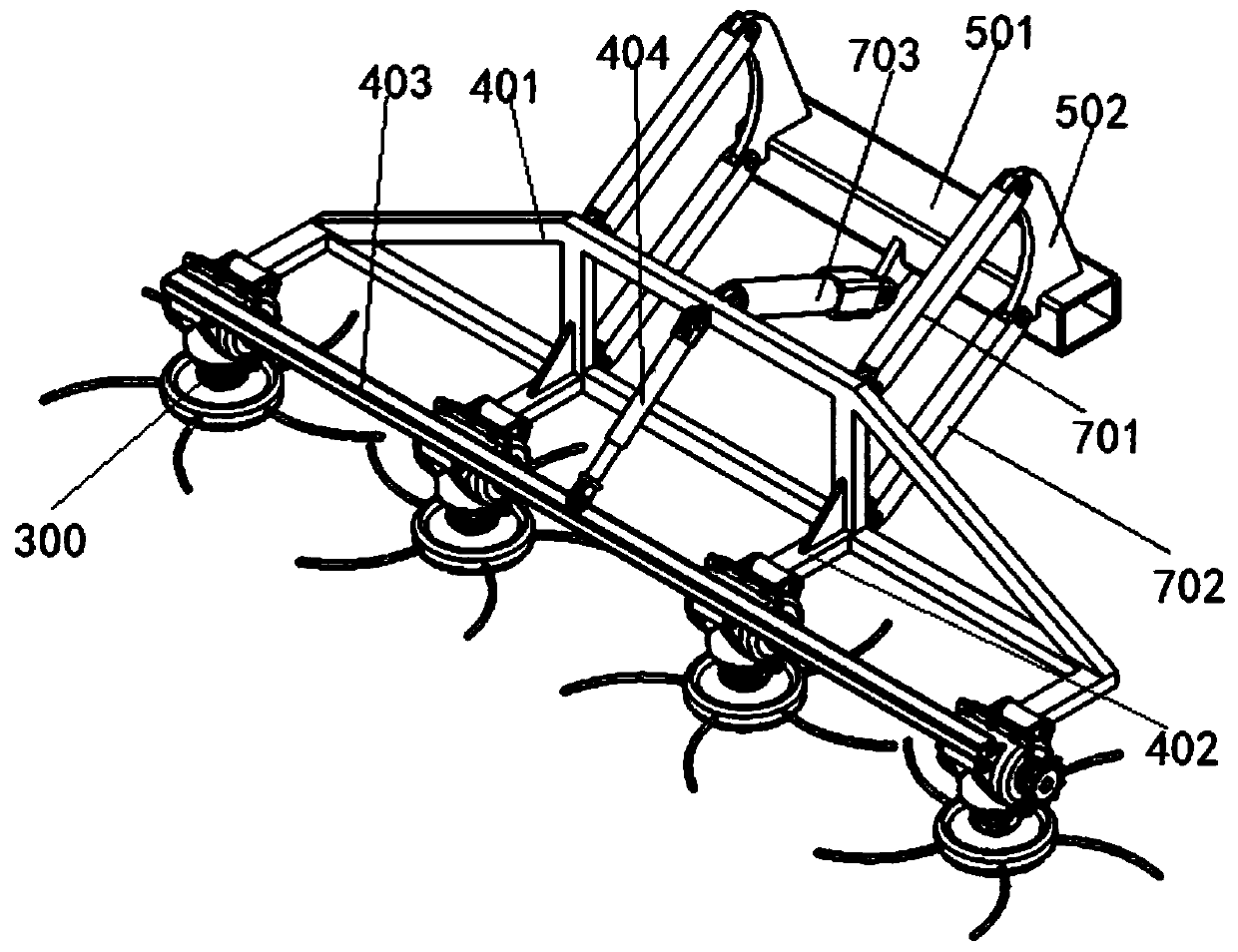

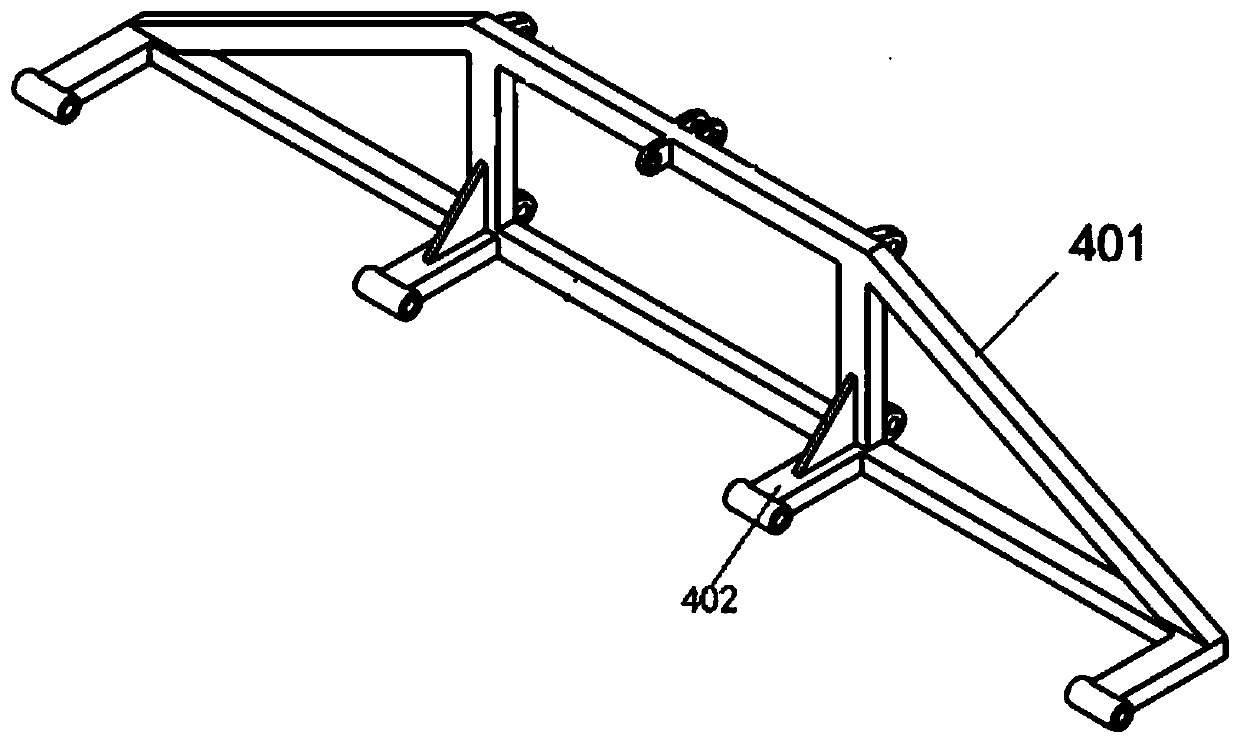

[0089] like figure 1 As shown, the present invention provides a high-gap corn detasseler, including a high-gap tractor 100 , a transmission mechanism 200 , and a cutting mechanism 300 . The high clearance tractor 100 includes a high clearance tractor frame 600 with wheels 210 rotatably arranged at four corners. Along the high ground clearance tractor frame 600 transverse direction and at the upper part of the front end of the high ground clearance tractor frame 600, a fixed mount 500 is fixedly arranged, and a cutter frame 400 is arranged in the gap in front of the fixed frame 500, and the cutter frame 400 is axially arranged on the cutter frame 400 front side. Cutters 300 are hinged at equal intervals, and adjacent cutters are connected by universal joint drive shafts. Bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com