A step-by-step stacking method for the initial unbalance of multi-level parts of large-scale high-speed rotary equipment based on convolutional neural network

A technology of convolutional neural network and balance, which is applied in the field of step-by-step stacking of initial unbalance of multi-level components of large-scale high-speed rotary equipment, can solve problems such as large vibration, poor assembly quality, and large unbalance of aero-engine rotors, and achieve improved The effect of efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

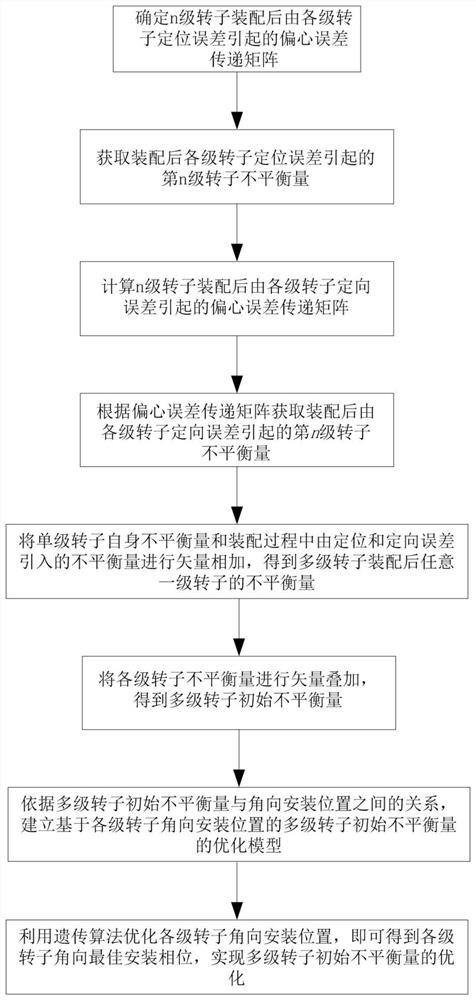

[0031] Based on the minimization of centroid and mass center, the method of stacking the initial unbalance of multi-level parts of large-scale high-speed rotary equipment step by step, such as figure 1 As shown, the method includes

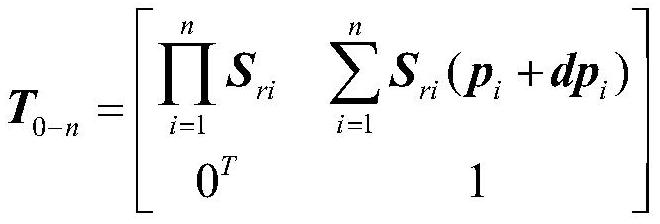

[0032] Step 1. During the assembly of the multi-stage rotor of the aero-engine, the positioning error of the single-stage rotor will be transmitted and accumulated, which will affect the accumulated eccentricity error of the assembled multi-stage rotor. Determine the eccentricity error transfer matrix caused by the positioning error of the rotors at each stage after the n-stage rotor is assembled, and the eccentricity error transfer matrix is:

[0033]

[0034] Among them, p i is the ideal position vector of the center of the radial measuring surface of the i-th rotor; dp iis the machining error vector of the center position of the radial measuring surface of the i-th rotor; S ri Rotate θ around the Z axis for the i-th stage rotor ri Rotati...

Embodiment 2

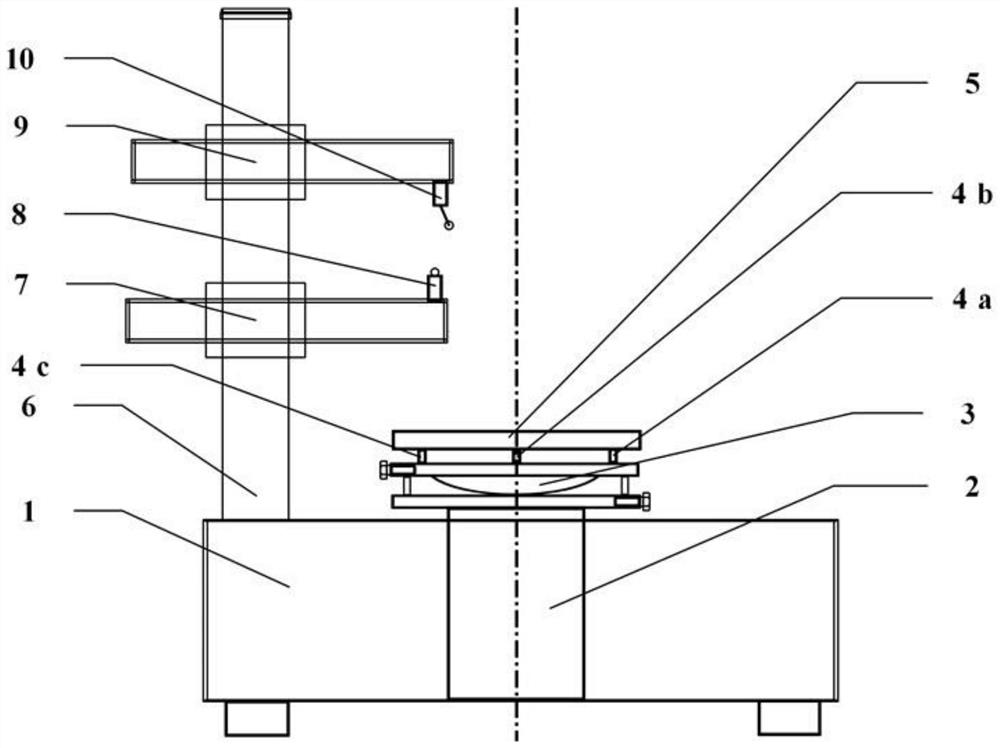

[0051] A step-by-step stacking device for the initial unbalance of multi-level parts of large-scale high-speed rotary equipment based on the minimization of centroid and mass center, such as figure 2 As shown, the device includes a base 1, an air bearing shafting 2, a centering and tilting workbench 3, precision force sensors 4a, 4b, 4c, a static balance measuring platform 5, a column 6, and a lower transverse measuring rod 7 , the lower telescopic inductive sensor 8, the upper horizontal measuring rod 9 and the upper lever inductive sensor 10; the air bearing shaft system 2 is nested in the center of the base 1, and the self-aligning and tilting workbench 3 is arranged on the air bearing shaft At the center of the system 2, three precision force sensors 4a, 4b, 4c are evenly arranged on the centering and tilting workbench 3; the static balance measurement platform 5 is on the three precision force sensors 4a, 4b, 4c; the column 6 is distributed on The left side of the air be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com