Reduction gear with multistage speed reducing function

A reducer and spindle technology, which is applied to mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems of complex structure of reducer, inconvenient maintenance or inspection, time-consuming and labor-intensive disassembly and assembly, and achieve the assembly process Smooth specification, high assembly efficiency, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described below in conjunction with accompanying drawing:

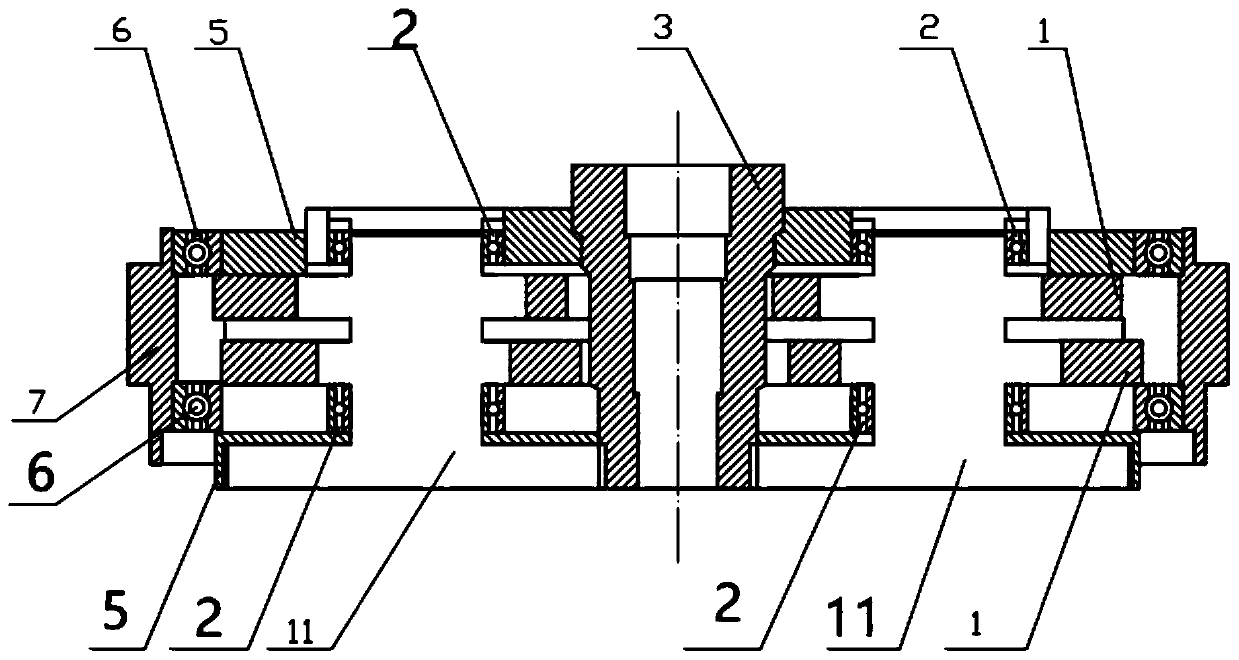

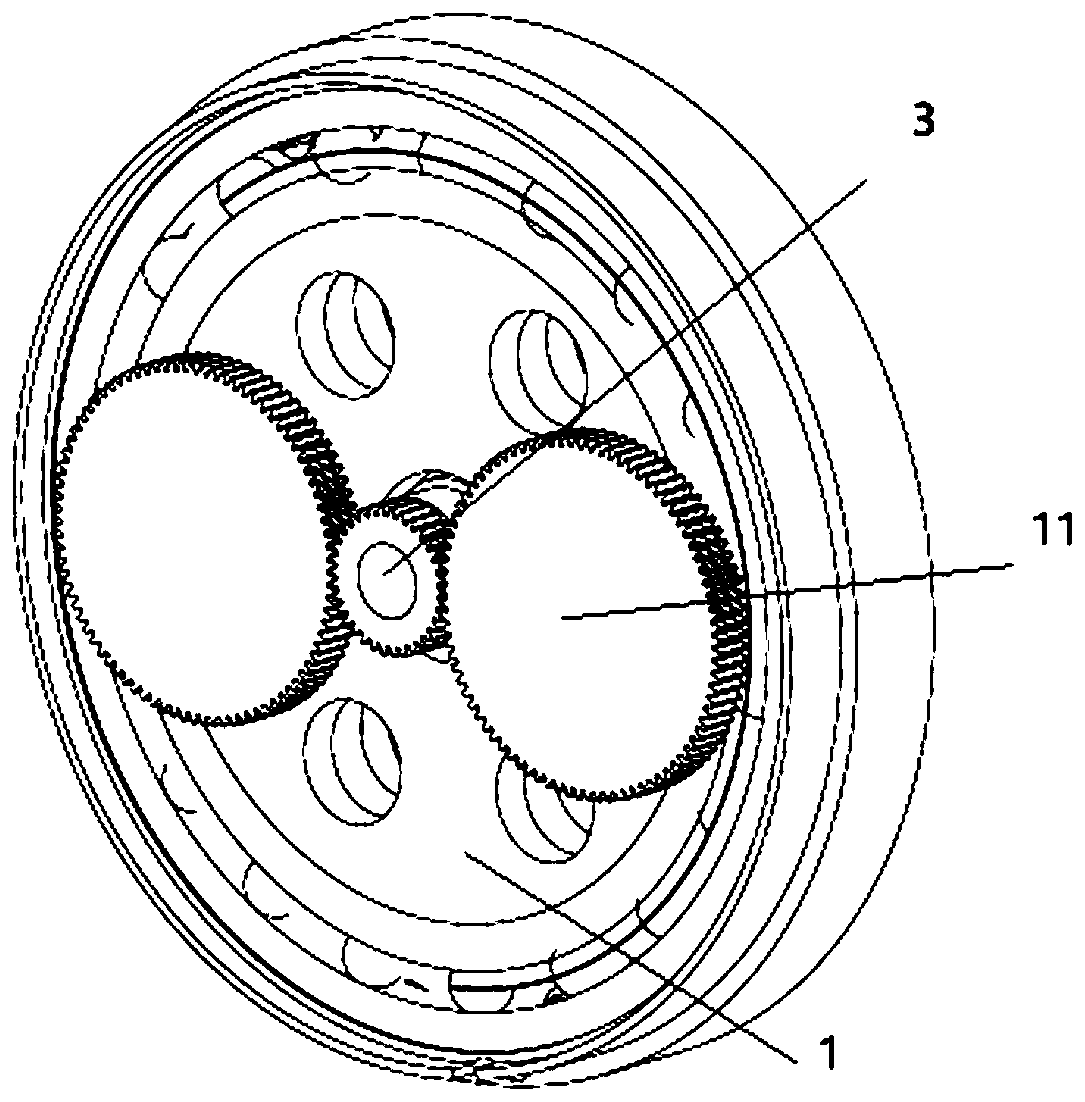

[0018] see figure 1 and figure 2 , a multi-stage deceleration reducer, including a main shaft 3, a planetary gear 11, a crankshaft 15, a housing 7 and a cycloidal pin wheel 1; the housing has a 7-bit hollow barrel structure, and the main shaft 3 is coaxially arranged on the housing 7 Geometric center; two crankshafts 15 are parallel to the main shaft 3 and arranged on a circle centered on the main shaft 3; the lower ends of the two crankshafts 15 are fixedly equipped with planetary gears 11, and the lower ends of the main shaft 3 are fixedly equipped with gears, and the gears are arranged on the two sides. The two planetary gears 11 are all meshed; the main shaft 3 is provided with two cycloidal pinwheels 1, and the cycloidal pinwheel 1 has a hole at the position of the crankshaft, and the crankshaft is set through the hole; the openings at both ends of the housing 7 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com