Construction method of green energy-saving building

A construction method and construction technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of unsatisfactory green energy-saving construction, waste of construction energy, and increased construction costs, so as to meet the requirements of green energy-saving and environmental protection construction, improve Construction efficiency and construction cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

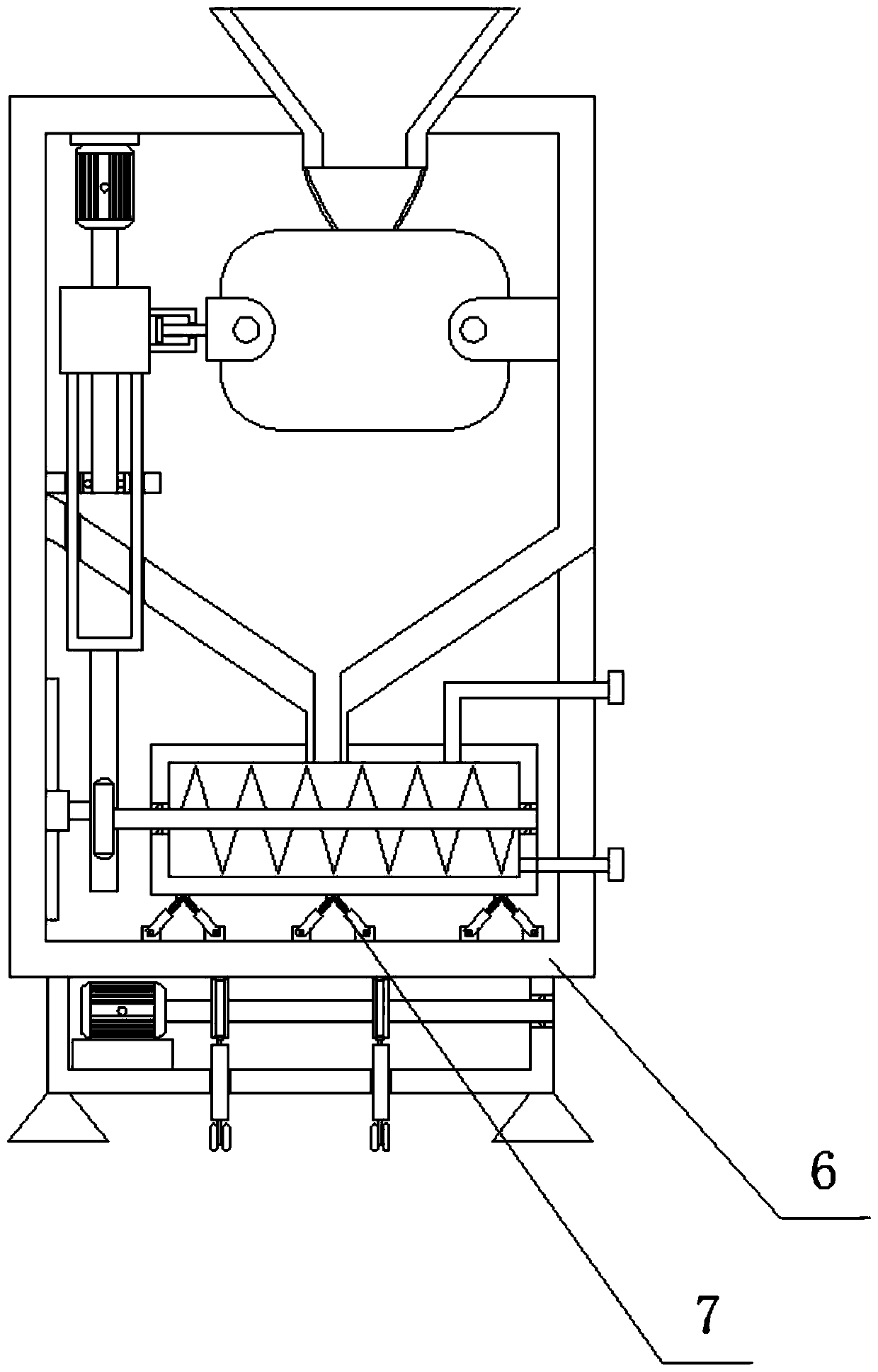

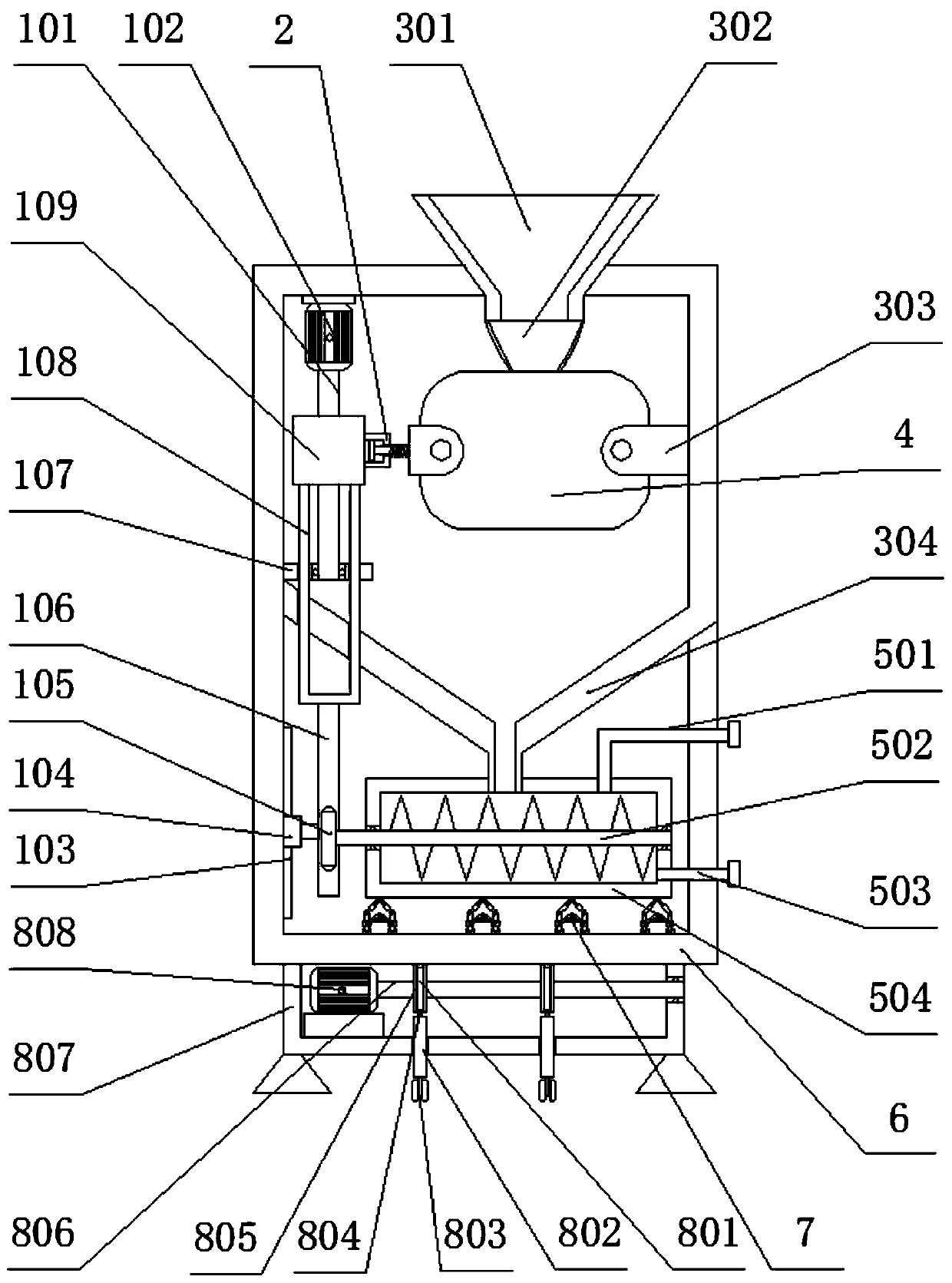

[0030] A construction method for a green energy-saving building, the method comprising the following steps:

[0031] Step 1: Grinding the construction waste with a crushing device to obtain crushed stone, stirring and mixing the crushed stone, base material, water, bacteriostat and water reducing agent through a crushing device to obtain raw material A, and mixing raw material A with expansion agent Stir to make concrete; this step realizes the crushing of construction waste through the crushing device and mixes the crushed construction waste to make concrete, and completes the two processes of crushing and mixing through one device, saving the transfer step of the crushed construction waste , improve efficiency and meet the requirements of green and energy-saving construction. At the same time, the device can prevent the growth of mold and other germs in the concrete by adding a bacteriostatic agent to the concrete, prolonging the service life of the concrete.

[0032] Step ...

Embodiment 2

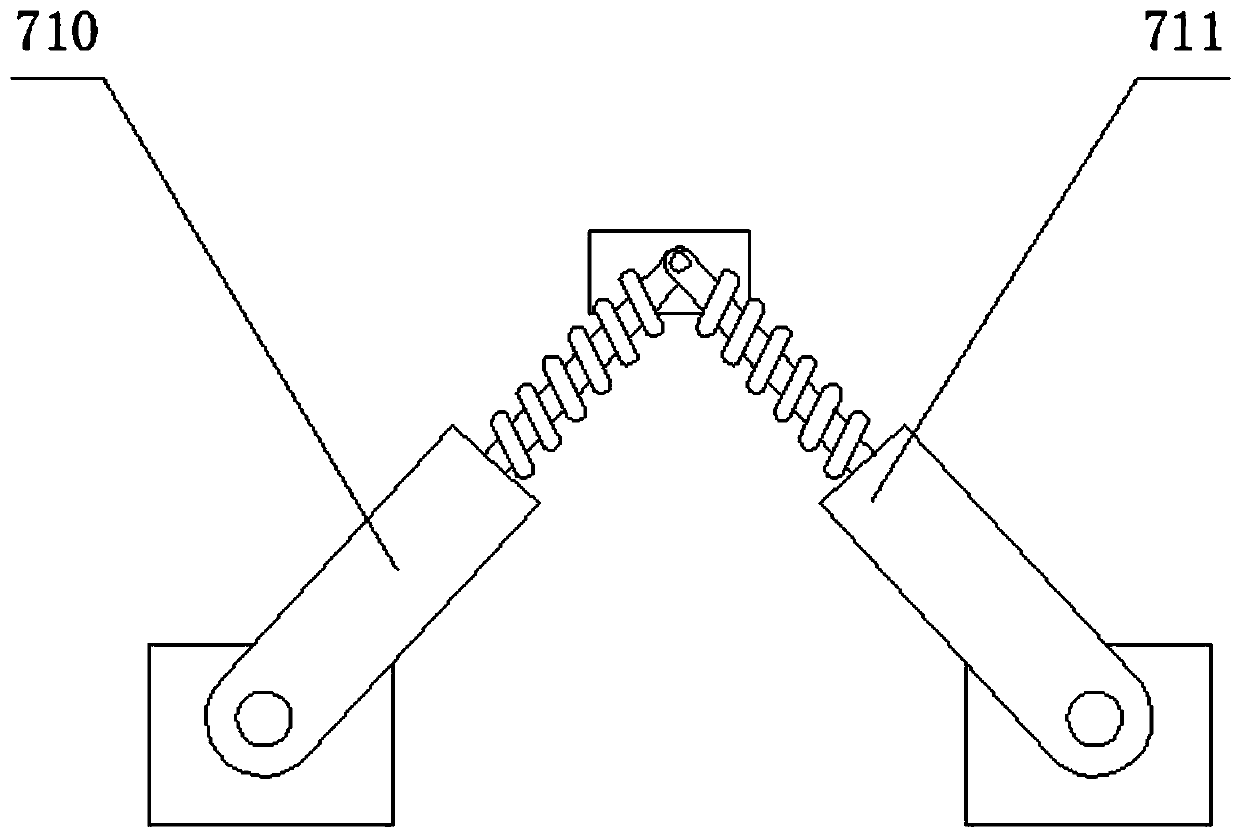

[0051] This embodiment adopts the same construction method for construction. The difference between this embodiment and Embodiment 1 is: (1) the content of each component in the raw material A is different; (2) the structure of the shock absorber 7 is different. details as follows:

[0052] The concrete content of each component in the raw material A in the present embodiment and embodiment one is as follows:

[0053] The parts by weight of each component of the raw material A are: 50 parts of gravel, 50 parts of base material, 200 parts of water, 10 parts of antibacterial agent, and 7 parts of water reducing agent. The ratio of the amount of expansion agent to the amount of raw material A is 0.2:1.

[0054] The components of the base material and the parts by weight of each component are: 40 parts of cement, 5 parts of lime, 30 parts of fly ash, 20 parts of plant ash, 8 parts of steel slag powder, 0.1 part of silicon carbide whiskers, alkali-resistant glass 30 parts of fiber,...

Embodiment 3

[0060] The construction method in this embodiment is the same as that in Embodiment 1, and the structure of the crushing device used is also the same, except that the content of each component in the raw material A in this embodiment is different, as follows:

[0061] The parts by weight of each component of raw material A in this embodiment are: 45 parts of gravel, 45 parts of base material, 150 parts of water, 13 parts of antibacterial agent, and 6 parts of water reducing agent. The weight ratio of the amount of expansion agent to raw material A is 0.3:1.

[0062] The components of the base material and the parts by weight of each component are: 35 parts of cement, 4 parts of lime, 35 parts of fly ash, 15 parts of plant ash, 7 parts of steel slag powder, 0.2 parts of silicon carbide whiskers, alkali-resistant glass 25 parts of fiber, 25 parts of cellulose acetate, 25 parts of styrene-acrylic latex powder, 12 parts of polyacrylate, 2 parts of polyoxypropylene glyceryl ether. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com