Prefabricated concrete construction column rammed earth wall provided with horizontal tie bars

A prefabricated concrete and structural column technology, which is applied to building structures, walls, building components, etc., can solve the problems of insignificant seismic performance and durability of rammed earth walls, tree felling, ecological environment, damage, etc., to improve the horizontal shear resistance. The effect of bearing capacity, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

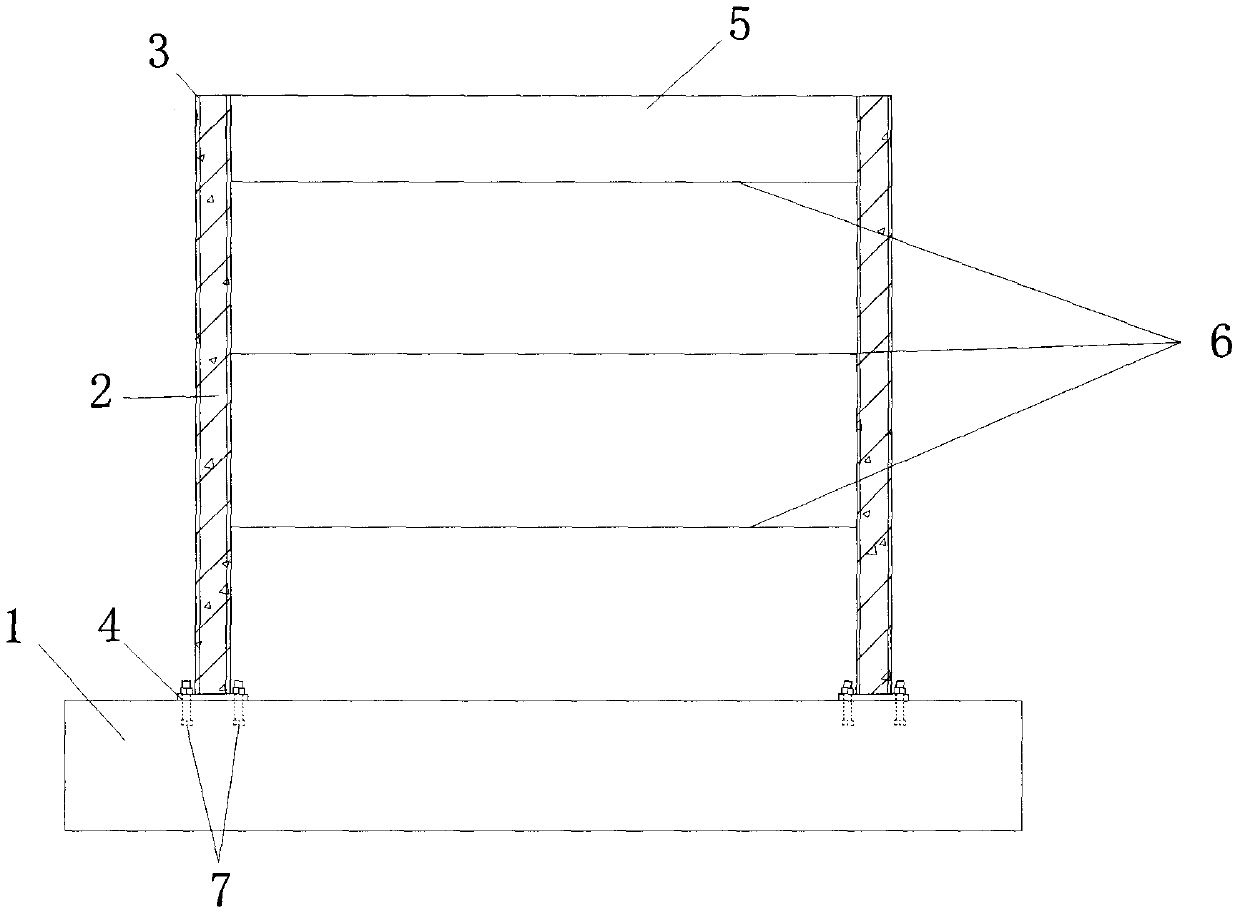

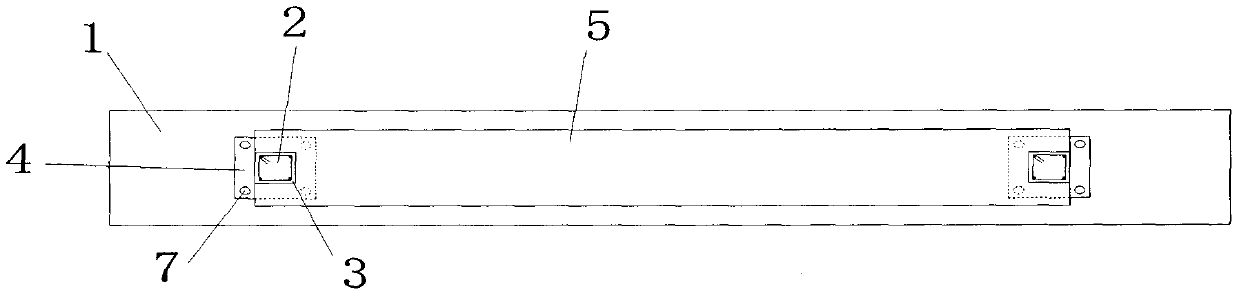

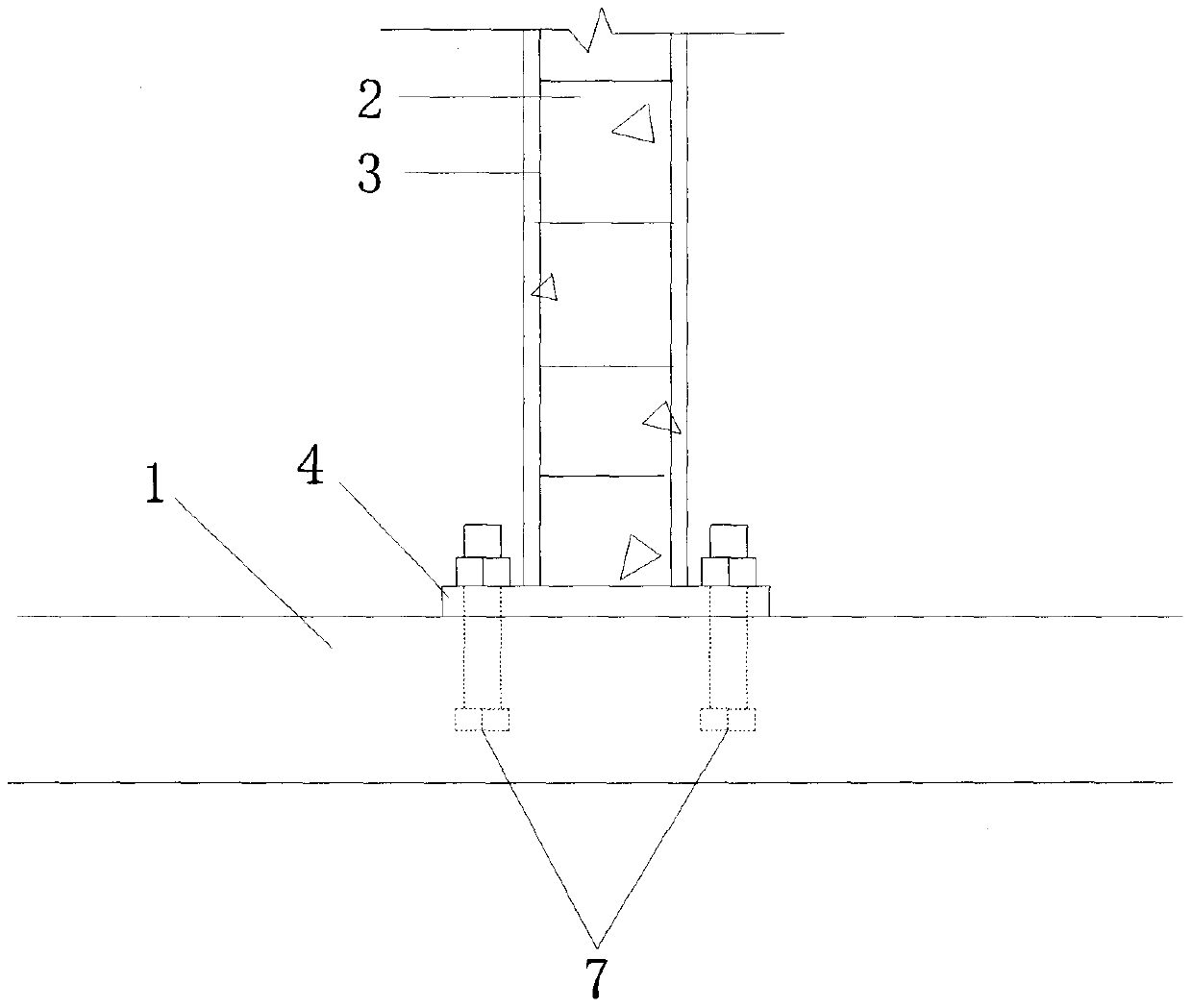

[0020] Such as Figure 1-3 As shown, the present invention includes a foundation ring beam 1, a precast concrete construction column 2, a construction column longitudinal reinforcement 3, a fixed plate 4, a rammed earth wall 5, tie materials 6, and embedded bolts 7; the precast concrete construction columns 2 are parallel There are two, respectively located on both sides of the rammed earth wall 5; the precast concrete construction column 2 is provided with four matrix-type precast concrete construction column longitudinal reinforcement 3, and the precast concrete construction column (2) Equipped with stirrups (8), the bottom of the precast concrete construction column 2 is provided with a fixed plate 4, and the fixed plate 4 is provided with reserved holes, and the two sides of the upper part of the foundation ring beam 1 are respectively provided with embedded bolts 7. The precast concrete construction column 2 is fixedly connected to the foundation ring beam 1 with embedded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com