Prefabricated columnar pier and construction method thereof

A technology of prefabricated assembly and prefabricated piers, applied in the erection/assembly of bridges, bridges, bridge parts, etc., can solve the complex setting of cast-in-place formwork or prefabricated segment formwork, the large volume and weight of the top prefabricated segment, and the large construction space requirement. and other problems, to achieve the effect of energy saving and environmental protection in the construction process, fast construction speed, and simple and fast installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

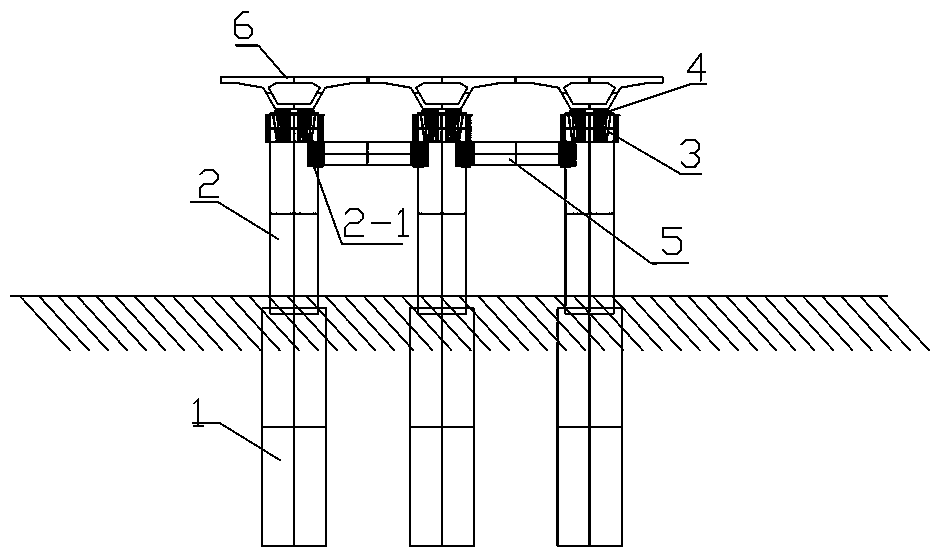

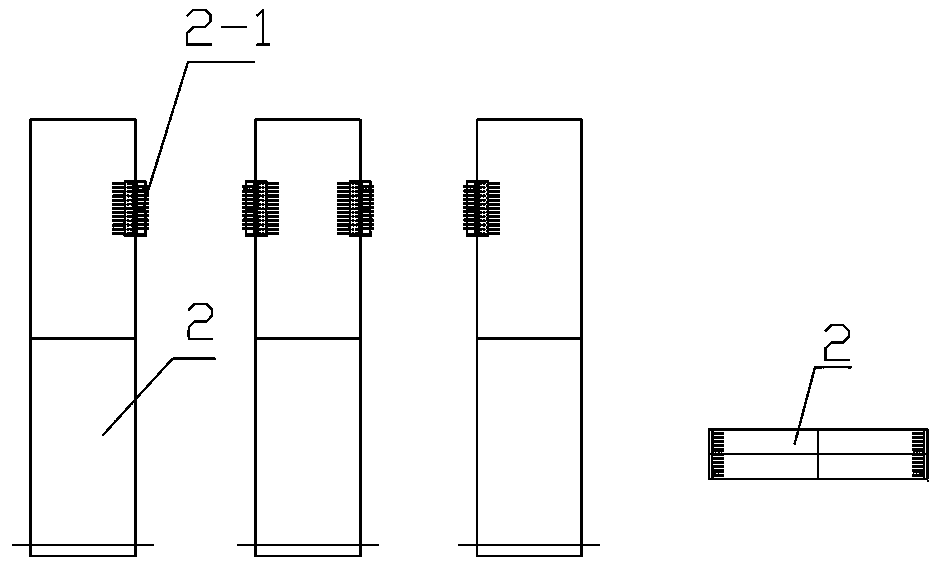

[0030] Such as Figure 1-2 As shown, the prefabricated assembled columnar bridge pier of the present invention includes a pile foundation 1 and a prefabricated pier column 2 installed on the pile foundation 1. A hoop platform 3 is installed on the top of the prefabricated pier column 2. On the hoop platform, The balance is provided with a temporary support 4 .

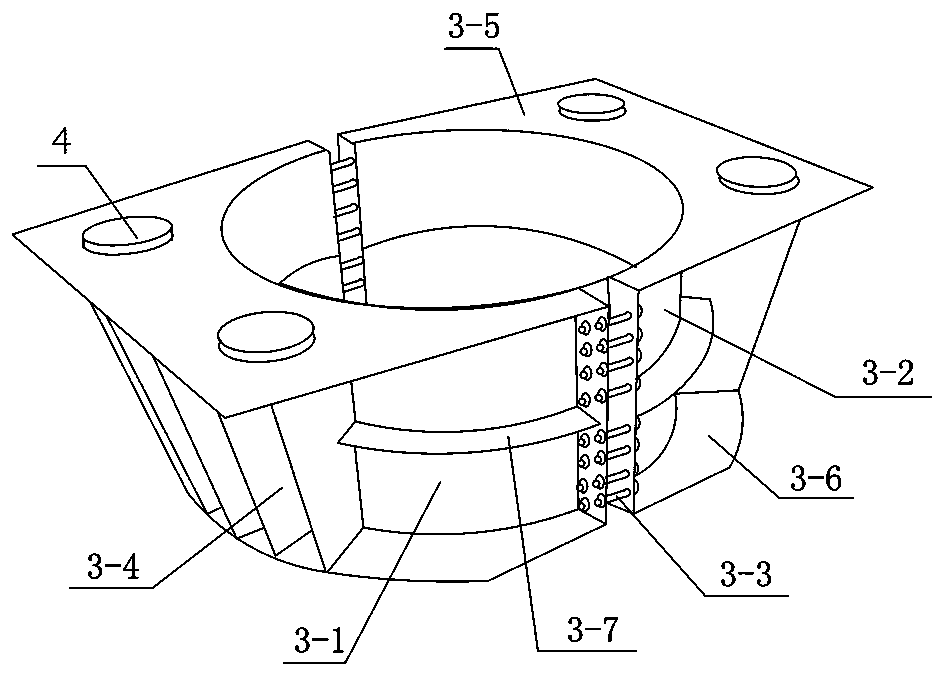

[0031] The hoop platform 3 of the present invention is composed of a sleeve formed by connecting the left arc-shaped plate 3-1 and the right arc-shaped plate 3-2 through the pre-tightening force bolt 3-3 pierced on the connecting side. Vertical stiffeners 3-4 are longitudinally arranged in the middle of the outer side walls of the arc-shaped plates; upper top plates 3-5 and lower bottom plates 3-6 extend horizontally at the upper and lower edges of the left and right arc-shaped plates, and temporary supports 4 Place on the surface of the upper top plate 3-5. Transverse stiffeners 3-7 are horizontally arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com