Warm-mix recycled asphalt modifier and preparation method thereof

A technology of recycled asphalt and modifier, applied in the field of road asphalt, can solve the problems of poor road performance and unusability of cold recycled asphalt mixture, and achieve the effects of reducing the risk of water damage, improving low-temperature performance and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a preparation method for the warm-mix recycled asphalt modifier, comprising the steps of:

[0030] (1) Weigh 55-65 parts of mineral spirits by weight and heat to 75-85°C;

[0031] (2) Add 8-20 parts of surfactant to the above-mentioned solvent oil, turn on the vacuum device and perform mechanical stirring for 20 minutes;

[0032] (3) Control the temperature down to 55°C-65°C, turn off the vacuum device, then add 25-35 parts of high-melting aromatic components into the above mixture, stir for 10-15 minutes, and cool to room temperature to obtain a warm-mix recycled asphalt modifier .

[0033] In the above step (2), the vacuum degree of the vacuum device is controlled at 30-40Pa.

[0034] In addition, in the embodiments of the present invention, the softening point test, ductility test and penetration test of warm-mix asphalt, the mixing and molding process test of warm-mix asphalt mixture, void ratio test, Marshall residual stability...

Embodiment 1

[0036] (1) Take 55 parts of lubricating oil base oil by weight and heat to 85°C;

[0037] (2) Mix 8 parts of saturated C 12 ~C 18 Add alkylpolypropylene polyamine to the above-mentioned lubricating base oil, turn on the vacuum device and carry out mechanical stirring, stirring for 20min, and the vacuum degree is 40Pa;

[0038] (3) Control the temperature down to 55°C, turn off the vacuum device, add 25 parts of S-200 solvent oil to the above mixture, stir for 10 minutes, and cool to room temperature to obtain a warm-mix recycled asphalt modifier.

[0039] Preparation of warm-mix recycled asphalt mixture: heat 40% of old asphalt mixture and 60% of new aggregate to a certain temperature; Then add new aggregate and new asphalt for mixing, that is, warm mix recycled asphalt mixture is prepared.

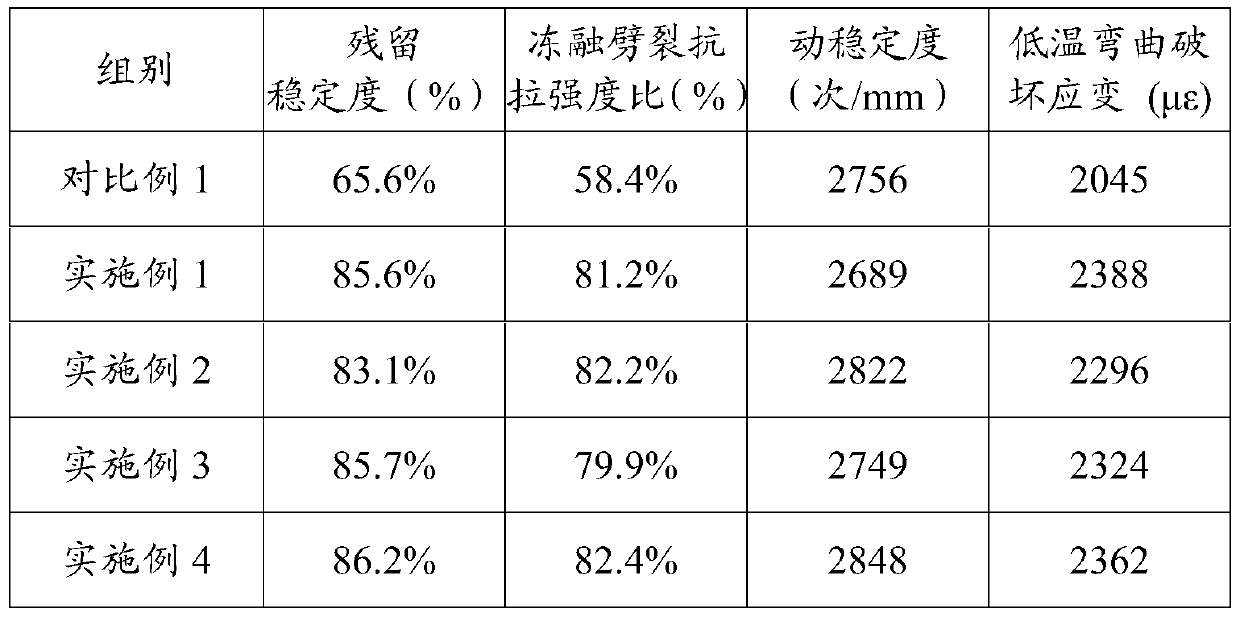

[0040] The specific technical indicators of the obtained warm-mix recycled asphalt mixture are shown in Table 1.

Embodiment 2

[0042] (1) Take by weight 65 parts of catalytic cracking oil slurry and heat to 75 ° C;

[0043] (2) Put 20 copies of C 12 ~C 18 Add fatty amidoamine to the cracked tar above, turn on the vacuum device and perform mechanical stirring, stir for 20min, and the vacuum degree is 30Pa;

[0044] (3) Control the temperature down to 65°C, turn off the vacuum device, add 35 parts of SH0004-90 solvent oil to the above mixture, stir for 15 minutes, and cool to room temperature to obtain a warm-mix recycled asphalt modifier.

[0045] Preparation of warm-mix recycled asphalt mixture: heat 50% of old asphalt mixture and 50% of new aggregate to a certain temperature; Then add new aggregate and new asphalt for mixing, that is, warm mix recycled asphalt mixture is prepared.

[0046] The specific technical indicators of the obtained warm-mix recycled asphalt mixture are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com