Fully-automatic filling system for barreled water

A filling system, fully automatic technology, applied in packaging, bottling machines, bottle filling, etc., can solve the problems of inconvenient use, low work efficiency, hidden dangers of drinking water safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

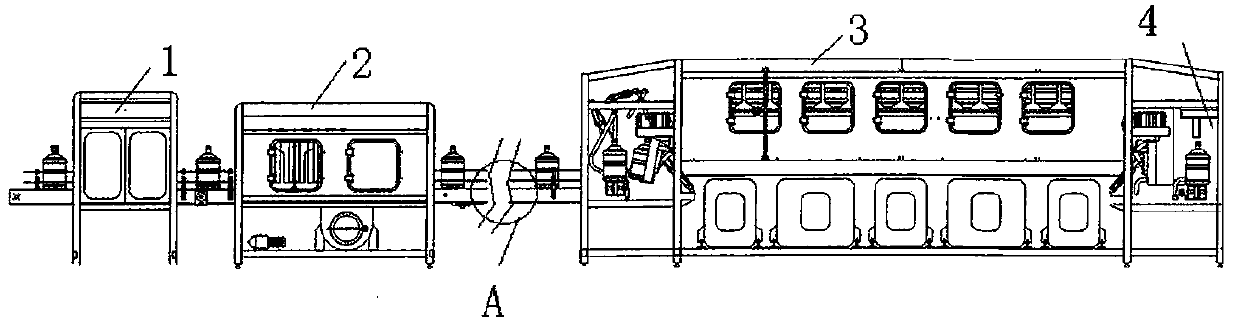

[0087] Such as Figure 1-46 As shown, a fully automatic filling system for bottled water, which sequentially includes an automatic cap removal machine 1, a bucket outer brush cleaning machine 2, a bucket cleaning machine 3, a bucket cleaning and disinfection machine, a filling machine 4 and Capping machine. The barrel cleaning and disinfection machine can be selectively installed according to production needs.

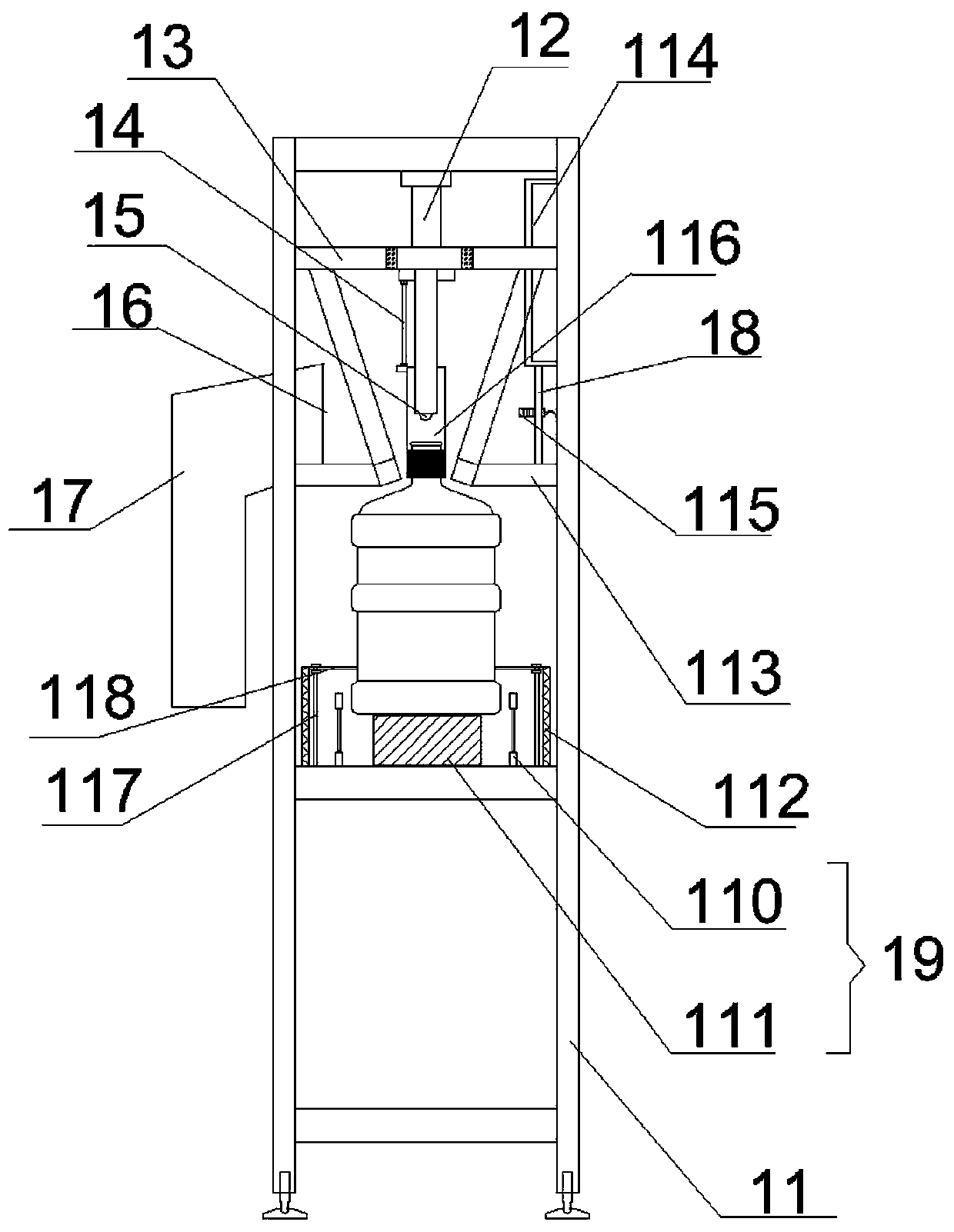

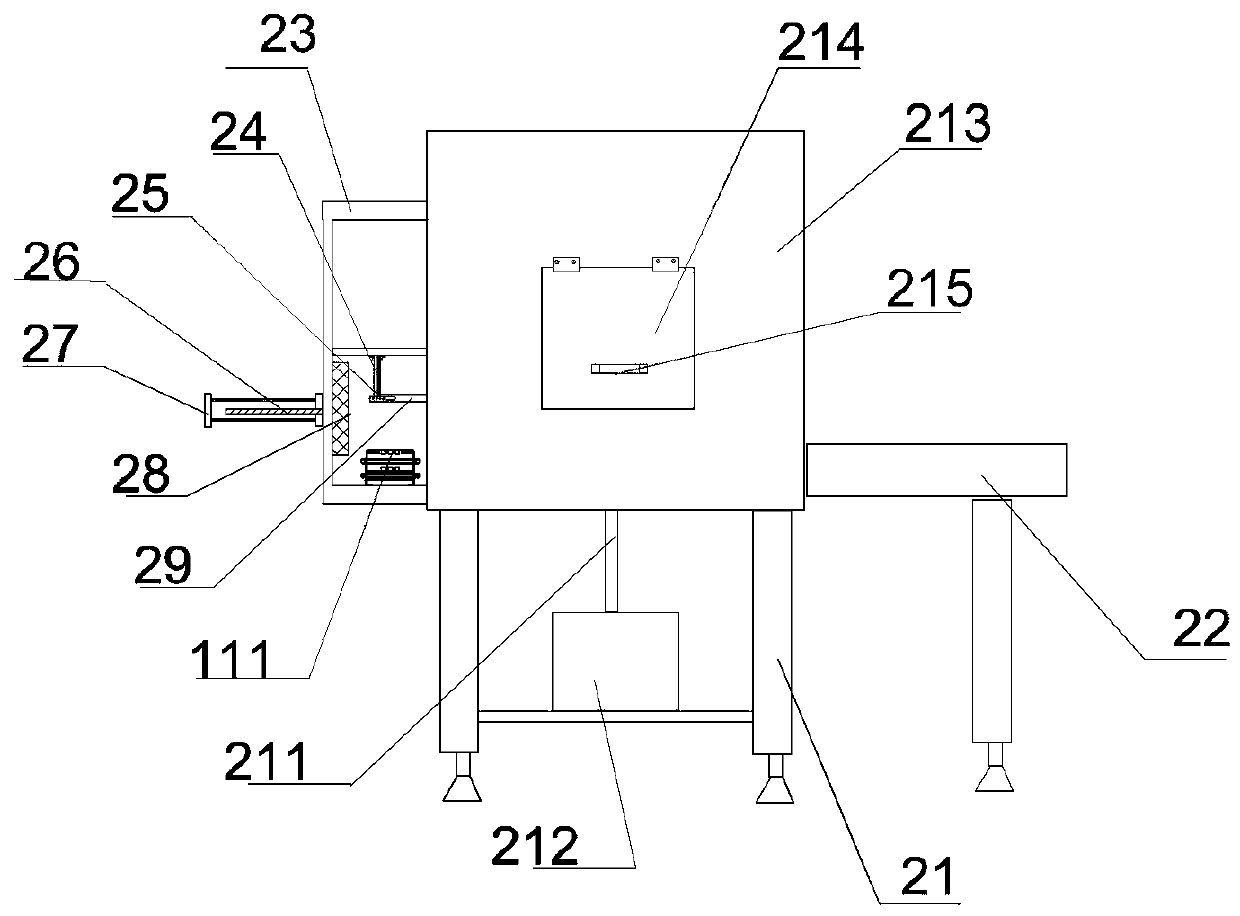

[0088] The automatic cap removal machine 1 includes a cube-shaped support frame 11, a cap removal mechanism located on the upper part of the support frame 11, a transmission mechanism for transporting buckets located below the cap removal mechanism and horizontally arranged in a direction perpendicular to the support frame 11. 19, and the bung collection box 17 located on one side of the support frame 11 and the blowing mechanism that is symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com