Helicopter fire-fighting pod for forest fire prevention

A forest fire prevention and helicopter technology, which is applied to aircraft parts, fire rescue, transportation and packaging, etc. It can solve the problems of aircraft flight safety hazards, changing the center of gravity of the pod, and low utilization, so as to avoid changes in the center of gravity of the pod and improve flight performance. Stability and the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

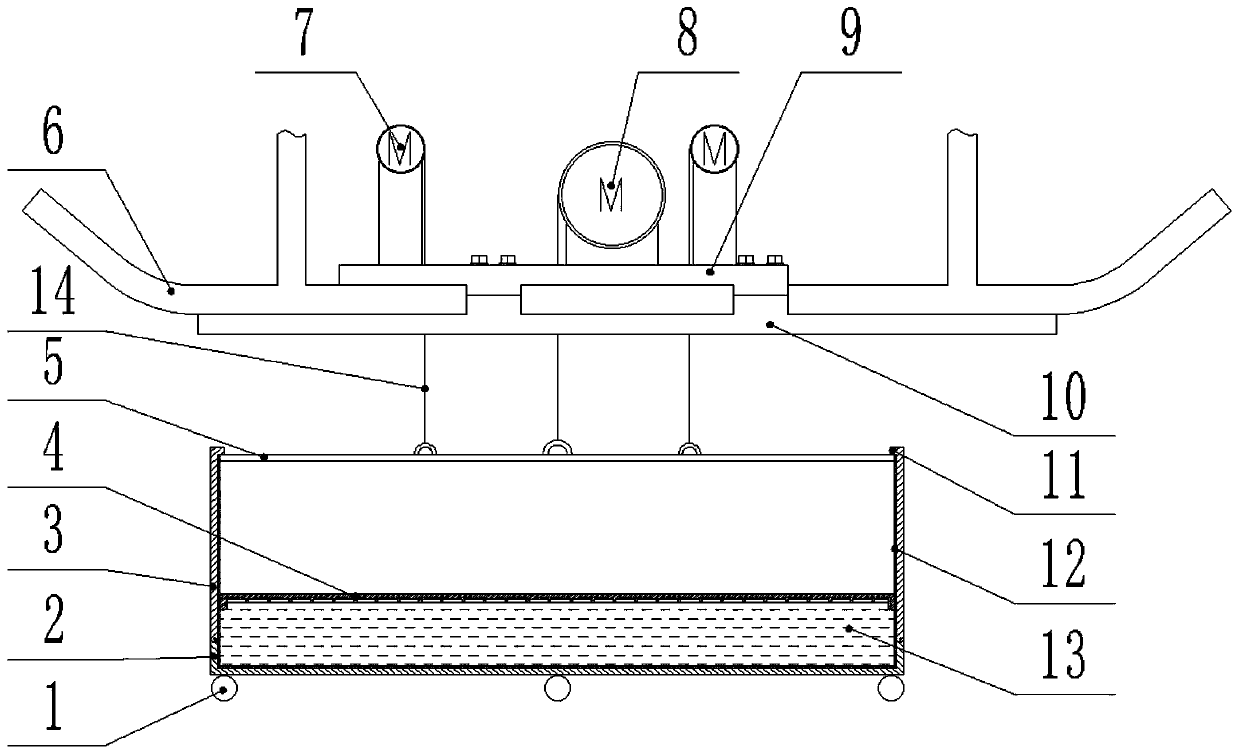

[0024] The present invention will be further described below in conjunction with the drawings:

[0025] This embodiment includes a hoisting mechanism and a pod, and the pod is connected to the hoisting mechanism through a hoisting rope 14. The above is a common structure in the prior art, and will not be repeated here.

[0026] The innovation of the present invention is to improve the lifting mechanism and the pod structure.

[0027] In the prior art, the strength of the hoisting mechanism built in the ordinary helicopter is low, and it is difficult to undertake the task of lifting the heavy load of the pod, while the special fire-fighting helicopter with built-in large hoist is expensive. For this reason, an external hoisting mechanism is used in the present invention The method realizes the function of large-load lifting (ie, pod lifting) on an ordinary helicopter. In the present invention, the structure of the lifting mechanism includes an upper plate 9, a lower plate 10 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com