Heat insulation pot cover capable of preventing steam scald

A pot lid and steam technology, applied in the direction of cooking utensil lids, cooking utensil special materials, etc., can solve the problems that the pot lid is easy to fluctuate and shake, easy to be scalded by steam, etc., to achieve good anti-scald heat insulation ability, increase length, and avoid accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

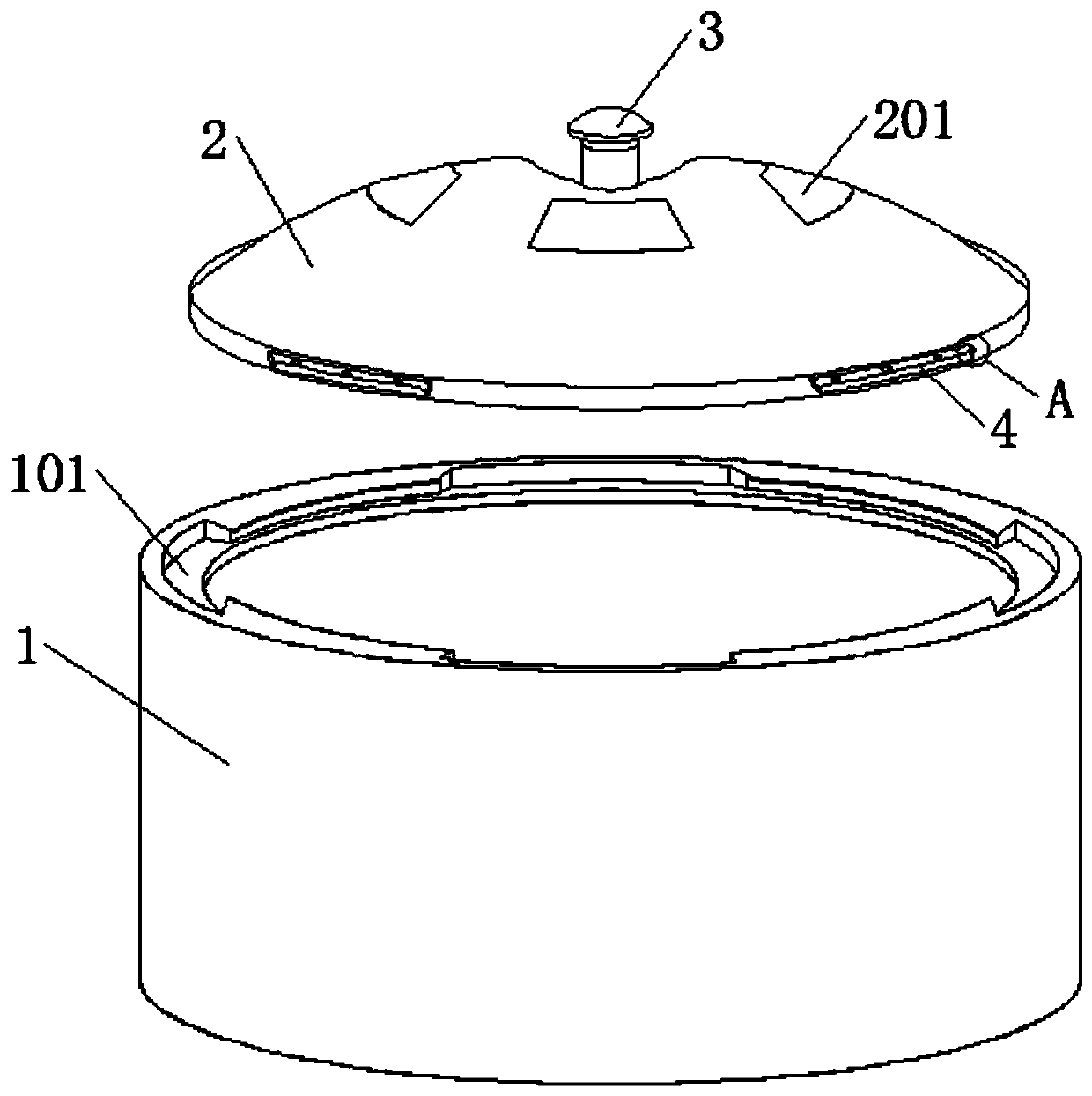

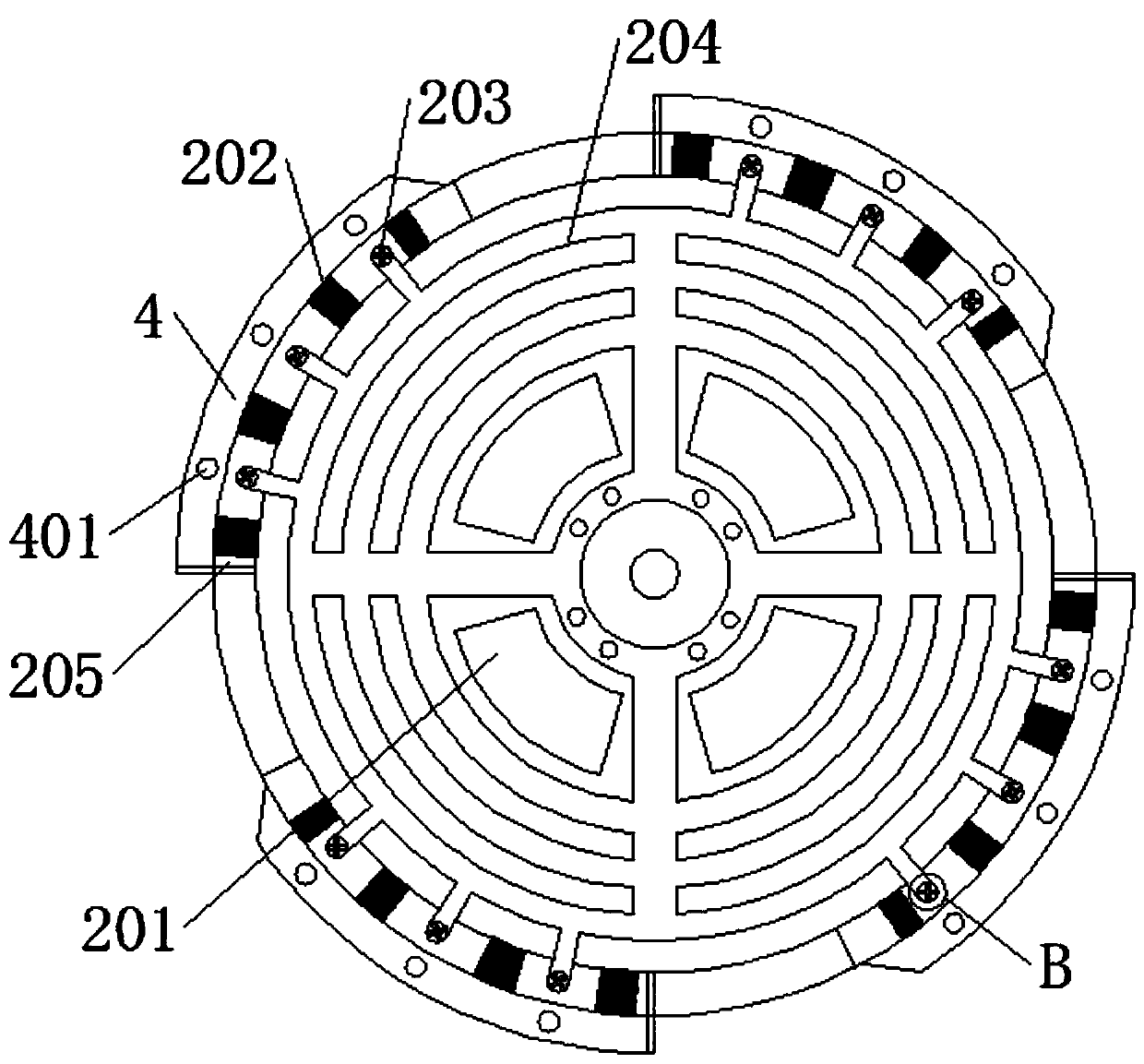

[0028] See attached figure 1 to attach Figure 8 , a heat-insulating pot cover for preventing steam burns, comprising: a pot body 1, a clamping groove 101, a heat-insulating pot cover 2, an observation glass 201, a spring column 202, an air guide hole 203, a miniature suction fan 2031, and a diffuser tube 204 , storage tank 205, upper heat insulation layer 206, lower heat insulation layer 207, adjustment handle 3, battery 301, tact switch 302, connecting column 303, bottom plate 304, contact block 3041, chute 305, card plate 4, conduction hole 401 and slide plate 402, the top of the inner wall of the pot body 1 is embedded with a clamping groove 101, the top of the pot body 1 is provided with a heat insulating pot cover 2, the top of the heat insulating pot cover 2 is fixedly connected with an adjustment handle 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com