dc-dc converter ventilation cooling device

A DC-DC, ventilation and heat dissipation technology, applied in the direction of output power conversion device, cooling/ventilation/heating transformation, electrical components, etc., can solve the problem of difficult heat dissipation of electronic fans, high overall energy consumption of the vehicle, and unfavorable ride comfort and other issues to achieve the effect of improving cooling effect, increasing service life and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

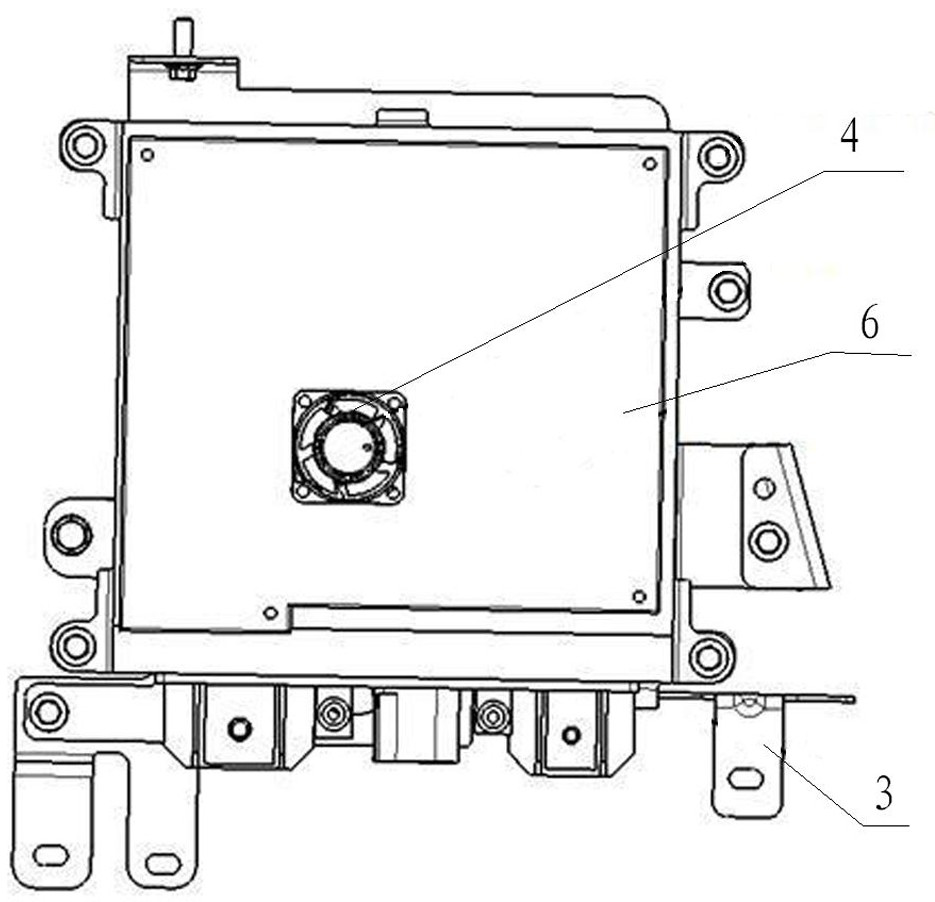

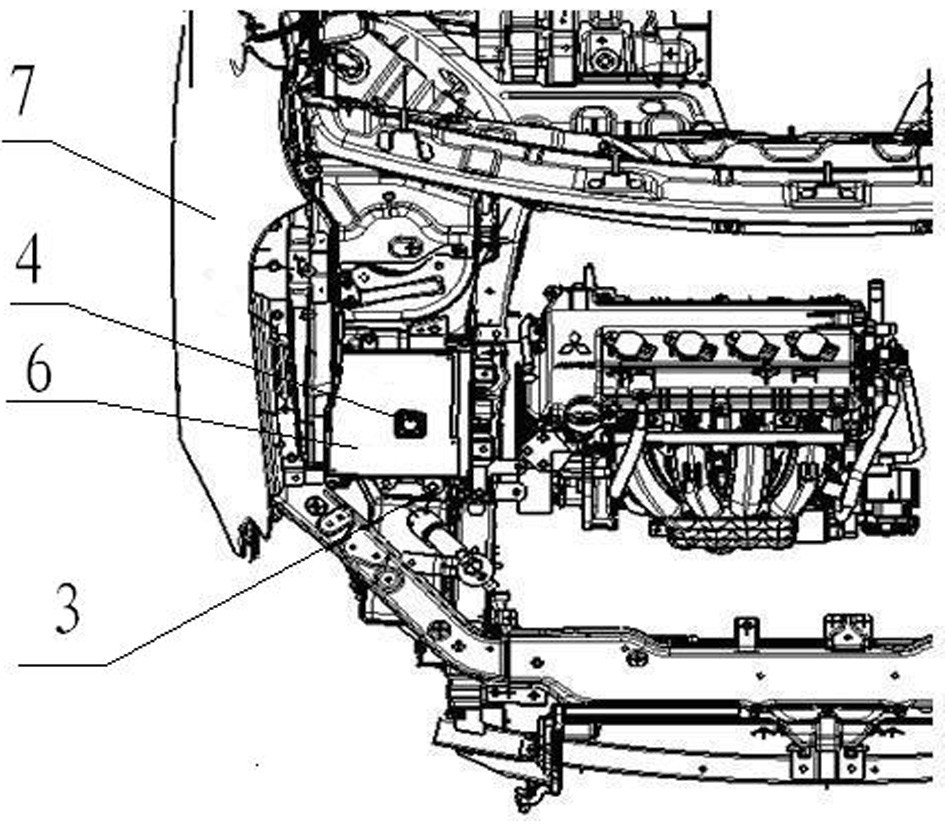

[0029] figure 1 and figure 2 What is shown is a schematic diagram of an existing cooling device for a DC-DC converter and its installation position in the nacelle. This structure has many problems as described in the background art, which will not be repeated here.

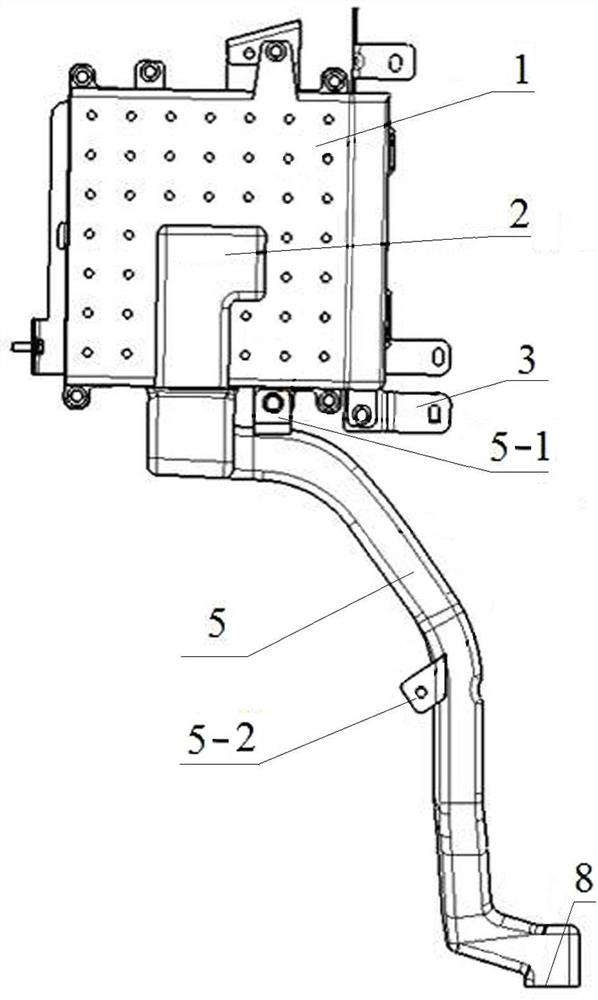

[0030] Figure 3 to Figure 6 The shown DC-DC converter ventilation and heat dissipation device includes a DC-DC converter body 6 installed on the DC-DC converter fixing bracket 3, an electronic fan 4 installed on the DC-DC converter body 6, and is provided with Diameter 6mm, hole pitch 28mm, heat dissipation cover plate 1 with multiple ventilation holes distributed in any adjacent diagonal four holes in a square shape is covered on the top surface of the DC-DC converter body 6, connected to the DC-DC by three bolts On the fixed bracket 3 of the converter, in order to improve the heat dissipation e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com