A parallel current sharing structure of silicon carbide mosfet

A silicon carbide, parallel technology, used in output power conversion devices, climate sustainability, electrical components, etc., can solve problems such as inconsistent driving signals and false turn-on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

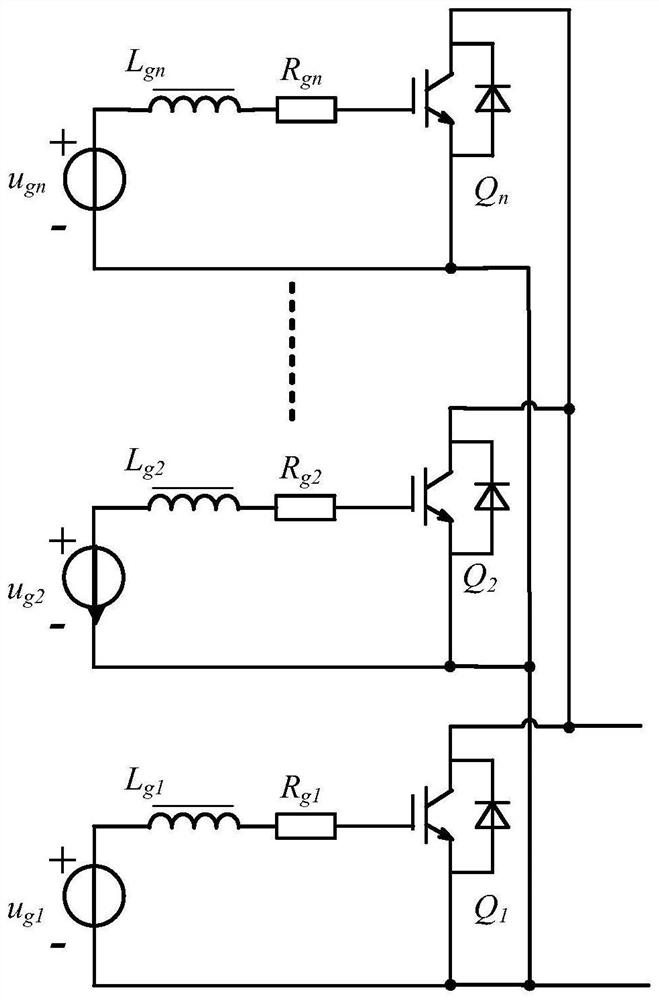

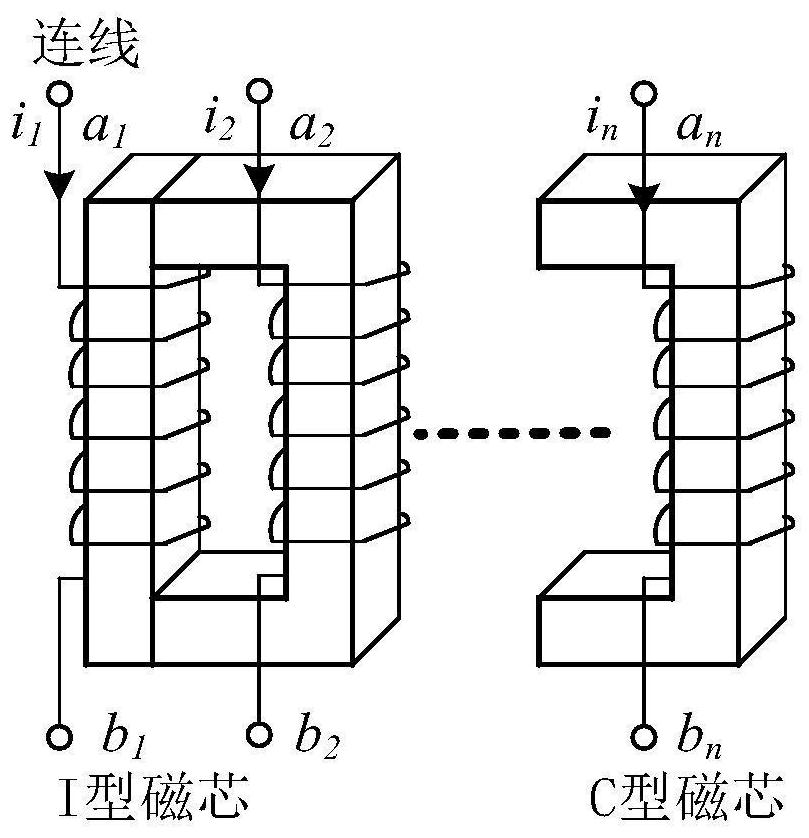

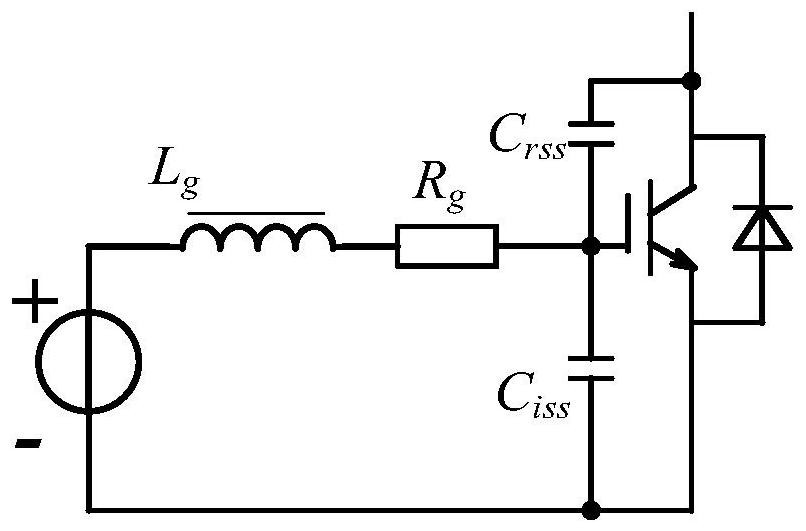

[0024] The silicon carbide parallel current sharing structure described in this example is composed of n stages, such as figure 1 shown, each stage consists of a SiC MOSFETQ 1 , Q 2 ,...,Q n and its driving circuit; in each driving circuit, each driving power supply is connected in series with a current sharing inductor, the current sharing inductor is connected to the driving resistor, and the driving resistor is connected to a single MOSFET, that is, the driving power u g1 , u g2 ,...,u gn The positive terminal of the current sharing inductor L is connected g1 , L g2 ,...,L gn One end a1, a2,..., an, current sharing inductor L g1 , L g2 ,...,L gn The other end b1, b2, ..., bn are respectively connected to the drive resistor R g1 , R g2 ,...,R gn One end of the drive resistor R g1 , R g2 ,...,R gn The other end of the single si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com