Fault propagation risk analysis method and prevention and control method based on a meta-motion chain

A technology of fault propagation and risk analysis, which is applied in the direction of instruments, calculations, and electrical digital data processing, etc., can solve problems such as increased workload and missing analysis results, and achieve the effect of reducing futile fault searches and improving the efficiency of fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation process of the present invention will be described below in conjunction with a pallet exchange rack system of a certain type of horizontal machining center.

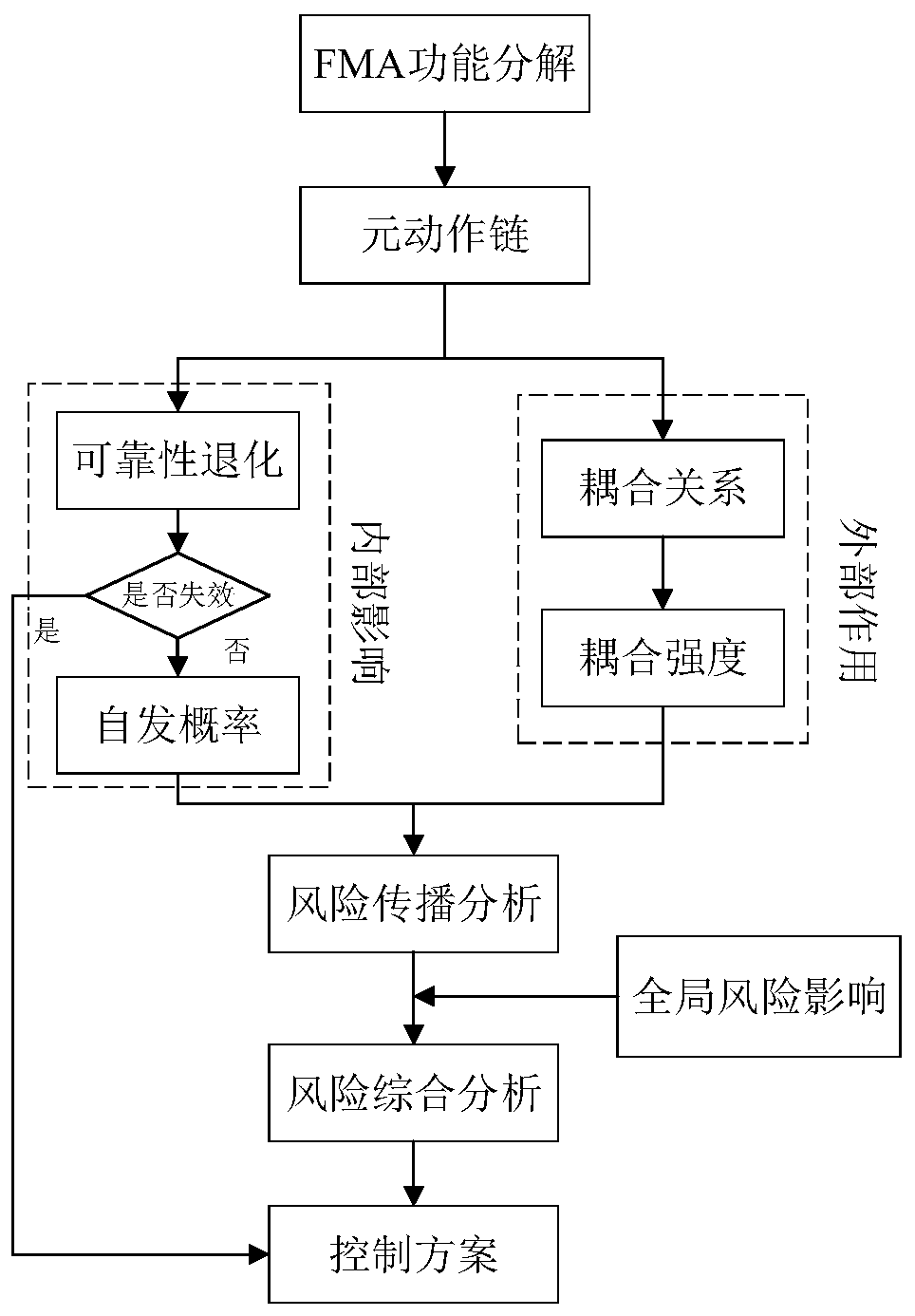

[0036] Such as figure 1 As shown, the principle of a fault propagation risk analysis and prevention and control method based on the meta-action chain is to determine its spontaneous probability according to the reliability distribution model of each meta-action on the meta-action chain. Then, the interactions among the meta-actions on each chain are identified and quantified to obtain the coupling strength value. According to the accumulative propagation of latent failures of meta-actions, a risk propagation model is established, and the risk criticality after meta-actions propagation is calculated. In addition, by combining the global risk impact and criticality after propagation, the comprehensive risk criticality of each meta-action is further determined and the risks are ranked. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com