Temperature control device applied to single resistance micro hot plate

A technology of temperature control device and micro-hot plate, applied in non-electric variable control, temperature control, control/regulation system, etc., can solve the problems of poor temperature control accuracy in high temperature area, no internal integration, narrow temperature control range, etc. Achieve the effect of reducing the temperature fluctuation range, realizing high integration and realizing internal integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings.

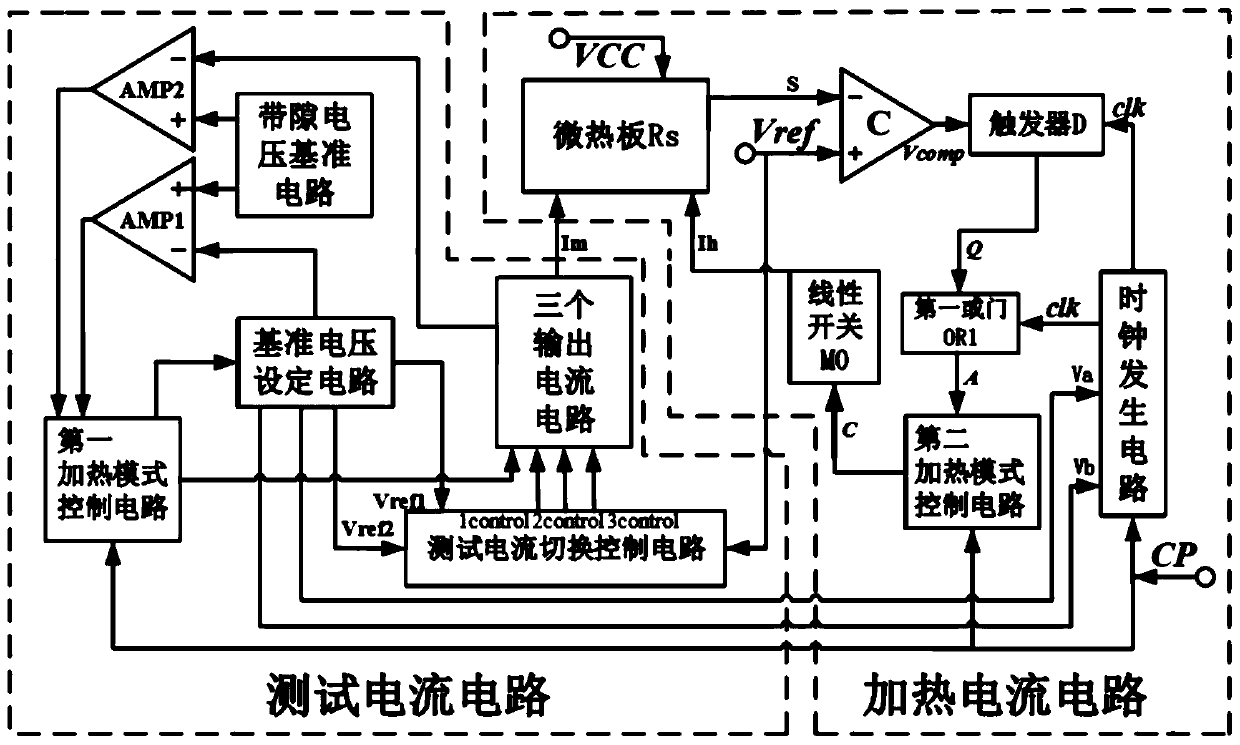

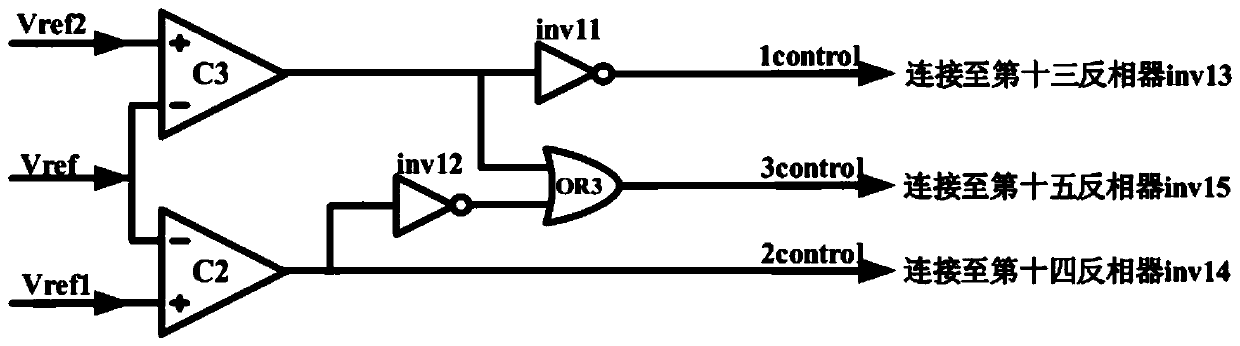

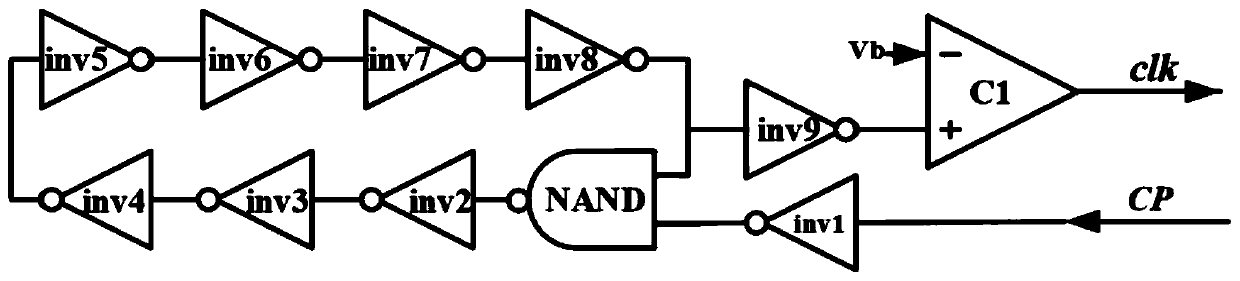

[0018] Such as figure 1 As shown, a temperature control device for a single resistance micro hot plate includes a test current circuit and a heating current circuit. The test current circuit includes a bandgap voltage reference circuit, a first operational amplifier AMP1, and a second operational amplifier AMP2 , The first heating mode control circuit, the test current switching control circuit, the reference voltage setting circuit and three output current circuits, the heating current circuit includes a micro hot plate Rs, a linear switch M0, a comparator C, a trigger D, The first OR gate OR1, the clock generation circuit and the second heating mode control circuit. The output of the first heating mode control circuit is connected to the input terminal of the reference voltage setting circuit and the input terminals of the three output current circuits respectively. The reference vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com