A kind of drying control method of disinfection cabinet

A technology for drying control and sterilization cabinet, applied in electrical program control, program control in sequence/logic controllers, instruments, etc., can solve the problem of long drying time, residual water after tableware drying, and insufficient drying time Long and other problems to achieve the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

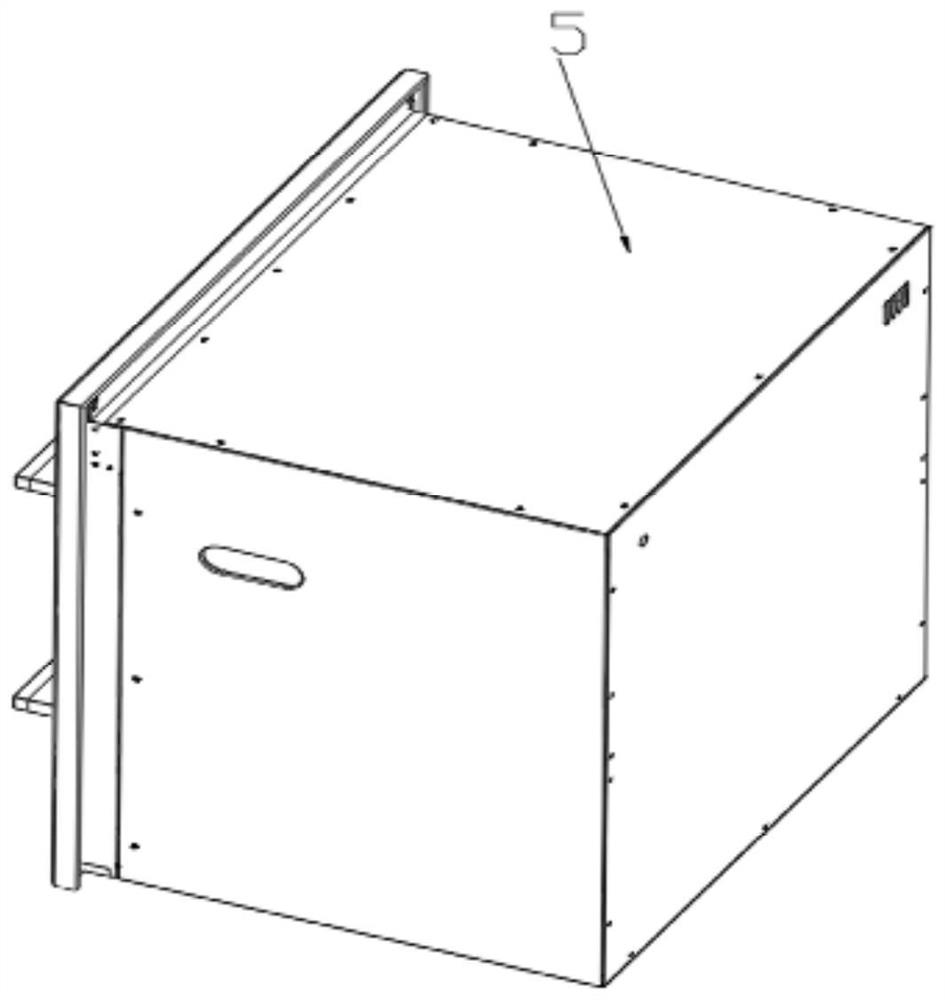

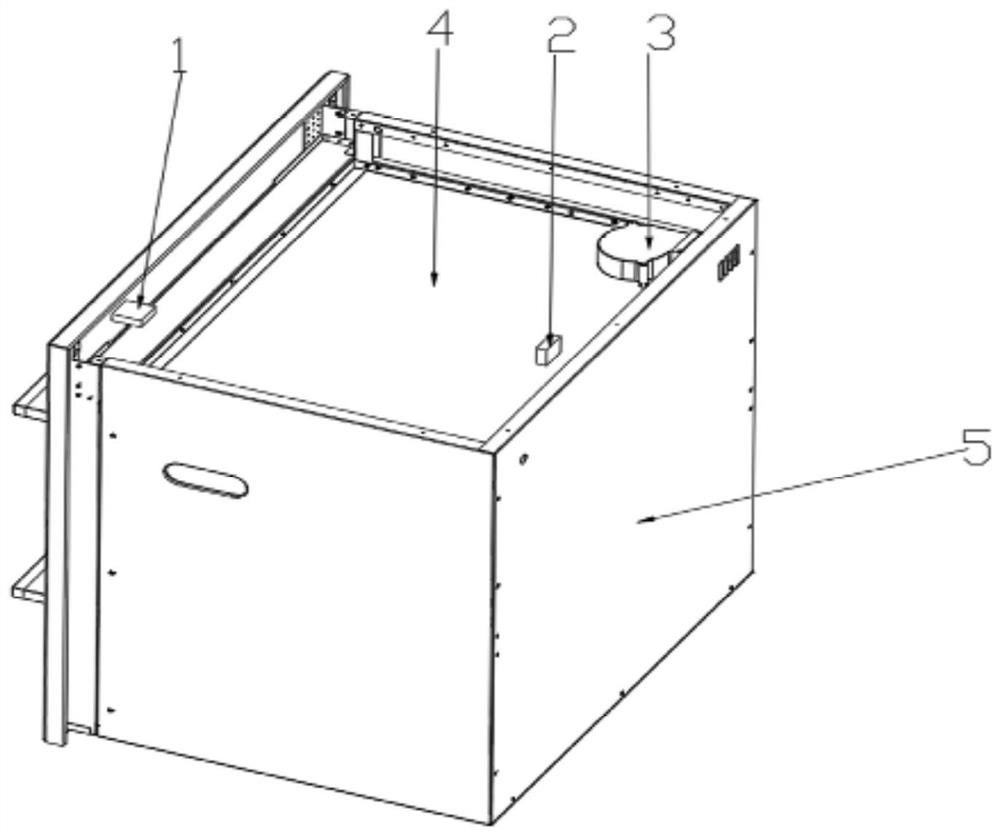

[0024] like figure 1 , 2 The disinfection cabinet shown includes an inner shell 4 and an outer shell 5 wrapped outside the inner shell. A cavity for disinfection is formed inside the inner shell 4, and a fan capable of exhausting the air in the cavity to the outside is installed between the inner shell and the outer shell. 3. The inner shell is provided with the first temperature and humidity sensor 2 for detecting the temperature and humidity in the cavity, the outer shell is provided with the second temperature and humidity sensor 1 for detecting the external humidity and temperature, the first temperature and humidity sensor, the second temperature and humidity sensor Both the sensor and the drying working module are electrically connected to the main controller.

[0025] After the drying module is started, the above-mentioned disinfectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com