Simulation device for dynamic real-time monitoring and analysis of heavy metal pollutant release from solid waste and application thereof

A solid waste, simulation device technology, applied in the direction of measuring devices, analyzing materials, testing metals, etc., can solve the problems of poor accuracy and reliability of experimental results, operational errors, errors, etc., to overcome the process of heavy metal extraction, accuracy and reliability. High reliability and easy operation

Active Publication Date: 2019-06-07

SHANXI DATONG UNIV

View PDF9 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the research on the environmental pollution potential of harmful elements in gangue is mainly realized through leaching and soaking experiments, but the leaching tests are all leaching tests, and the data monitoring and analysis are carried out separately. Extraction steps, and the manual operation process is prone to large errors and operational errors, resulting in generally poor accuracy and reliability of experimental results

Although at present, some scholars have proposed the idea

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

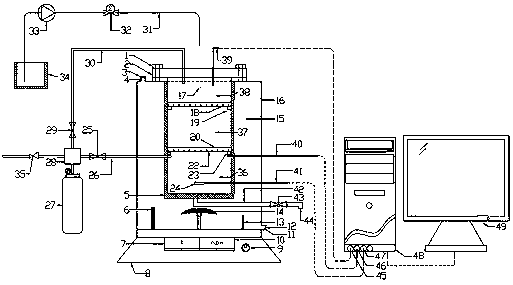

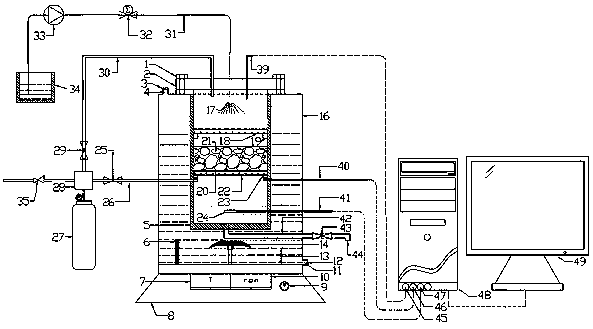

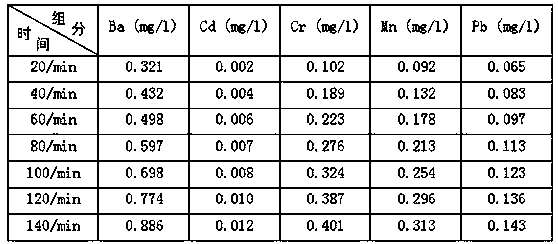

The invention relates to a simulation device for dynamic real-time monitoring and analysis of heavy metal pollutant release from solid waste and an application thereof. The simulation device is suitable for dynamic real-time monitoring and online data analysis of heavy metal pollutant release from coal gangue under various working conditions, especially under temperature-pressure coupling conditions. A leaching device comprises a leaching state simulation unit, a pressure water supply and gas supply unit and a heavy metal pollutant online monitoring and data processing unit. The leaching statesimulation unit is provided with a water mist space, a sample filling space and a leachate collection space. The leaching state simulation unit also has a hot bath heating function. The pressure water supply and gas supply unit can provide spray liquid and gas of certain pressure for the leaching state simulation unit. The heavy metal pollutant online monitoring and data processing unit can realize real-time monitoring and online data processing of the heavy metal ion concentration in the coal gangue leachate. The device of the invention has the advantages of simple structure, convenient operation, high degree of automation and intelligence, and high accuracy of dynamic leaching simulation effect.

Description

technical field [0001] The invention belongs to the field of solid waste environmental pollution monitoring, in particular to a simulation device for dynamic real-time monitoring and analysis of the release of heavy metal pollutants in coal gangue, and also relates to the specific application of the simulation device. Background technique [0002] Coal gangue is a mixture of carbonaceous rock, argillaceous rock, sandy rock, siltstone and a small amount of limestone discharged during coal mining and coal preparation plant production. It is the waste discharged from the above two production processes. For every 100 million tons of coal produced, about 14 million tons of gangue are emitted, of which about 20 million tons of gangue are discharged after washing 100 million tons of coking coal, and 15 million tons of gangue are discharged after washing of 100 million tons of steam coal. The accumulative stockpile and annual discharge of coal gangue in my country is one of the large...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N23/223G01N33/20

Inventor 罗化峰乔元栋王森关铁钢王家栋赵潞恒杨磊李灿

Owner SHANXI DATONG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com