Hydrostatic testing machine for ultra-large drift diameter cast pipe

A hydraulic testing machine and diameter technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. problems, to achieve the effect of perfect function, improved service life and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

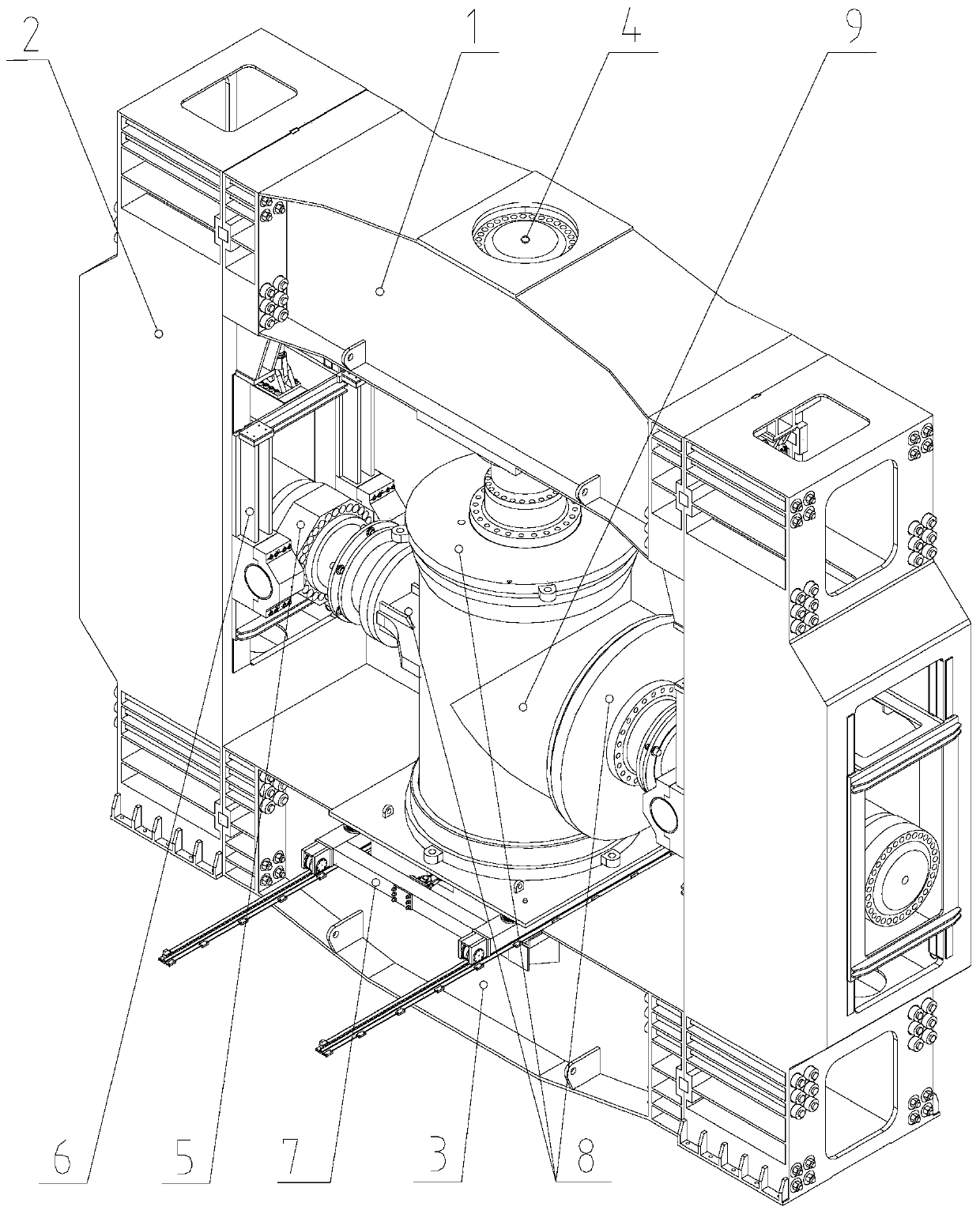

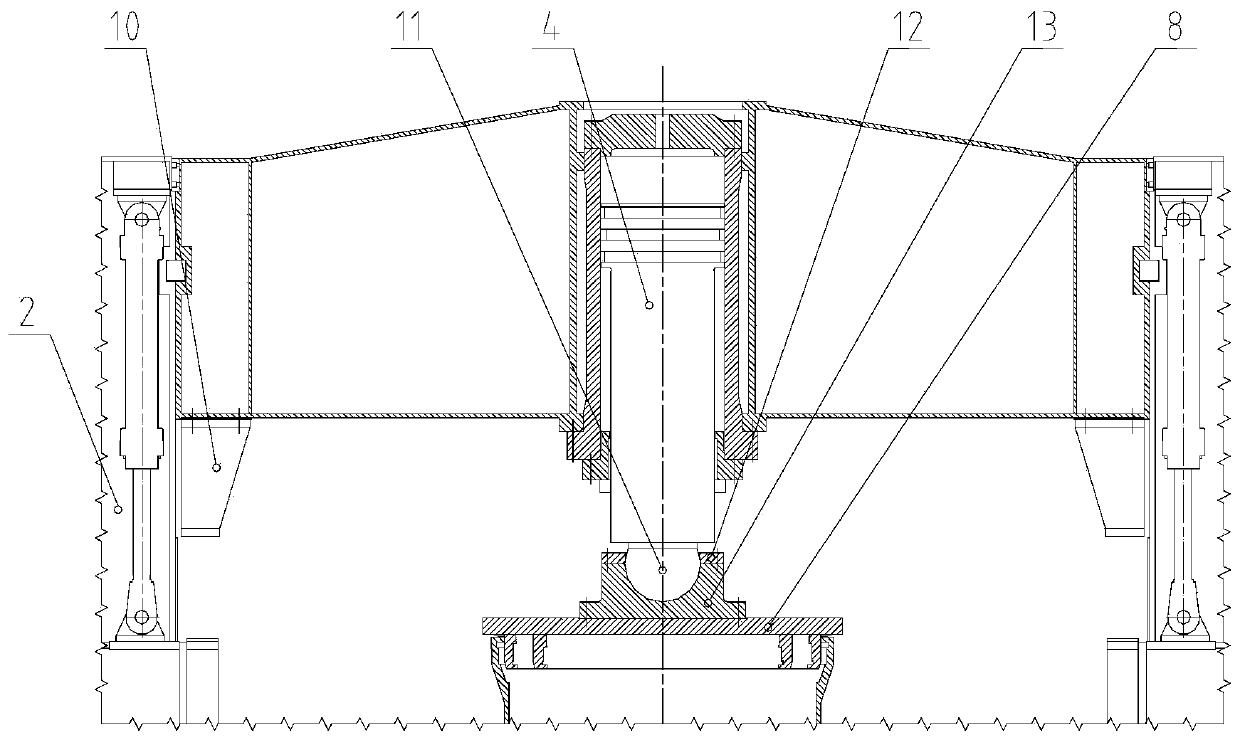

[0061] like Figure 1-9 And shown in 12, the present invention provides a kind of hydraulic pressure testing machine that is used for super-large-diameter cast pipe fitting; The sealing tool is used for sealing, and the corresponding tooling is installed on the main cylinder, the cylinders on the left and right sides, and the platform of the trolley. After the mobile trolley carries the pressure test pipe fittings into the equipment, the main cylinder is moved downward and pressurized, and the pipe fittings are moved up and down by the tooling. Seal and press tightly. Then adjust the height of the center of the side cylinder by lifting the oil cylinder so that the center of the right (left) side cylinder is aligned with the center of the middle hole of the tee pipe fitting, then the side cylinder moves forward and pressurizes, and seals the middle hole of the pipe fitting through the radial sealing tooling of the socket and press tight. The right (left) side is in contact wi...

Embodiment 2

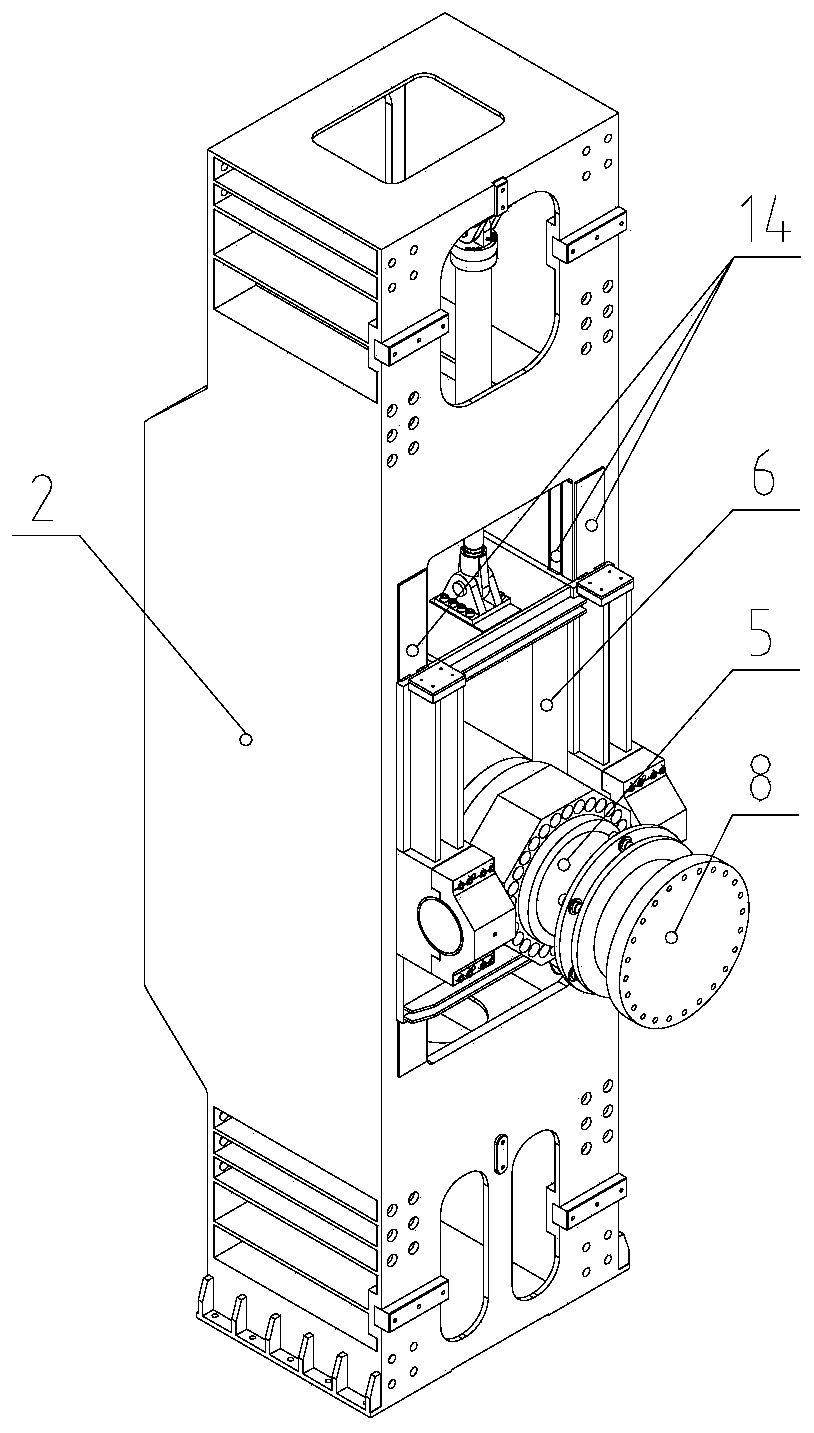

[0064] like Figure 10 , 11 Shown, (on the basis of embodiment 1,) the present invention also provides a kind of hydraulic pressure testing machine that is used for super large-diameter cast pipe fitting; Sealing, install the corresponding tooling on the left cylinder and the right cylinder respectively, install the adjustment square box and the corresponding elbow bracket on the trolley platform, adjust the center height of the elbow by adjusting the combination of the square box, and adjust the tilt of the side cylinder by rotating the oil cylinder Angle, lift the side cylinder drive mechanism to the top dead center through the lifting cylinder and hold it, then the side cylinder moves forward and pressurizes, and seals and compresses the two holes of the elbow pipe fitting through the socket radial sealing tool. The sealing needs of elbows of various specifications can be realized.

[0065] After the pipe fittings are sealed, water is injected into the pipe fittings throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com