Negative pressure pneumatic conveying experiment device and experiment method

A negative pressure pneumatic conveying and experimental device technology, applied in the direction of measuring devices, testing/calibrating devices, instruments, etc., can solve problems such as weighing accuracy errors, calibration work difficulties, time and space differences, etc., and achieve the goal of improving calibration accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

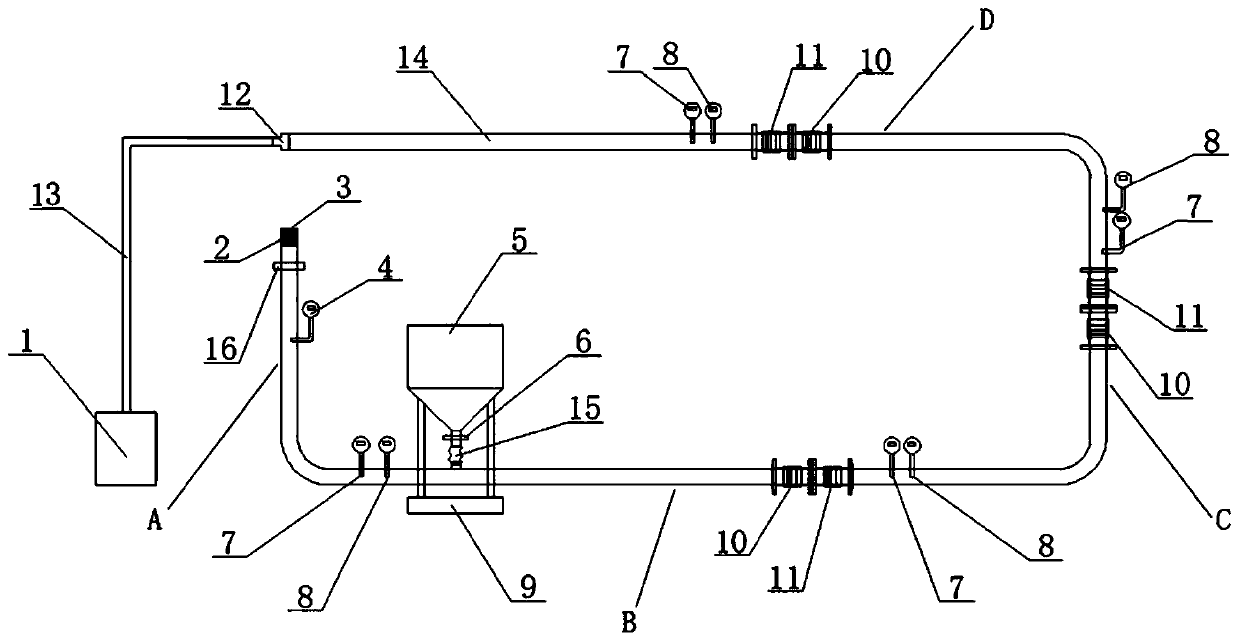

[0022] The negative pressure pneumatic conveying experimental device and experimental method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] The negative pressure pneumatic conveying experimental device of the present invention is structurally connected as figure 1 As shown, it mainly includes the following structures: industrial vacuum cleaner 1, wind speed sensor 4, feeder 5, temperature sensor 7, pressure sensor 8, electronic scale 9, sight glass 10, mass flow meter 11, and material conveying pipeline 14.

[0024] The feeder 5 is connected to the front end of the material conveying pipeline 14 through a flexible connecting pipe 15 . A check valve 6 is installed at the connection between the feeder 5 and the flexible connecting pipe 15 . Feeding machine 5 is placed on the electronic scale 9. As a preferred mode of the present invention, the motor of the feeder 5 is a variable frequency motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com