Flexible temperature-strain integrated sensor array and preparation method thereof

A technology of integrated sensors and temperature sensors, applied in the field of sensors, can solve problems such as difficult layout, numerous leads, cumbersome sensor pasting process, etc., and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] Another aspect of the present invention also provides a method for preparing the flexible temperature-strain integrated sensor array in any one of the above embodiments, including the following steps:

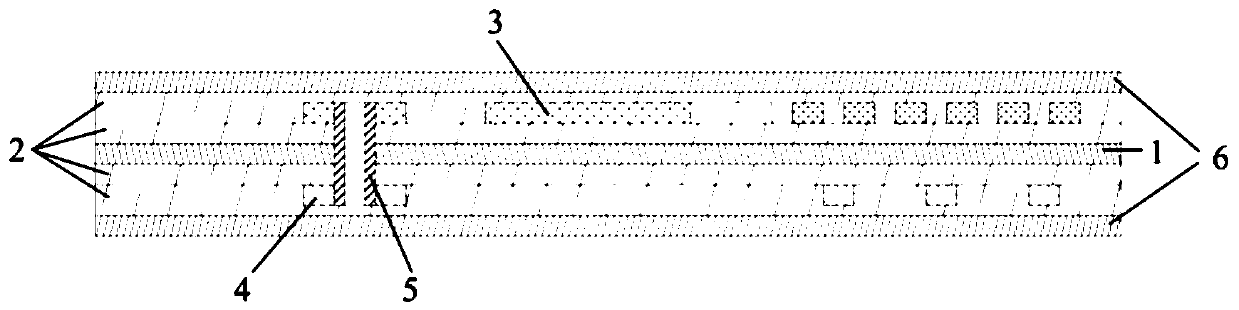

[0063] S1: Material forming: make flexible substrate, copper foil and constantan foil into design size;

[0064] S2: Lamination of foil materials: Lamination of constantan foil and copper foil to the upper and lower sides of the substrate by means of gluing;

[0065]S3: Drilling: Drilling at the preset positive and negative nodes of the temperature sensor;

[0066] S4: Plated through hole: Copper is plated on the hole wall to make the constantan foil and copper foil on both sides of the substrate conductive;

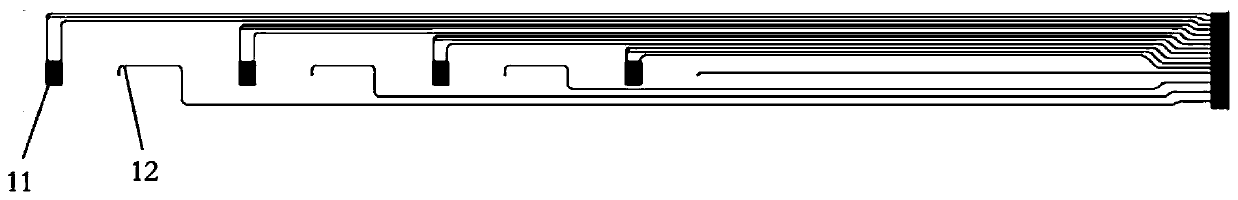

[0067] S5: Patterning: use photochemical methods to pattern the copper foil layer and constantan foil layer to form sensor arrays, leads and pads;

[0068] S6: Covering the protective layer: Cover the sensitive units and leads of the temperature sensor and strain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com