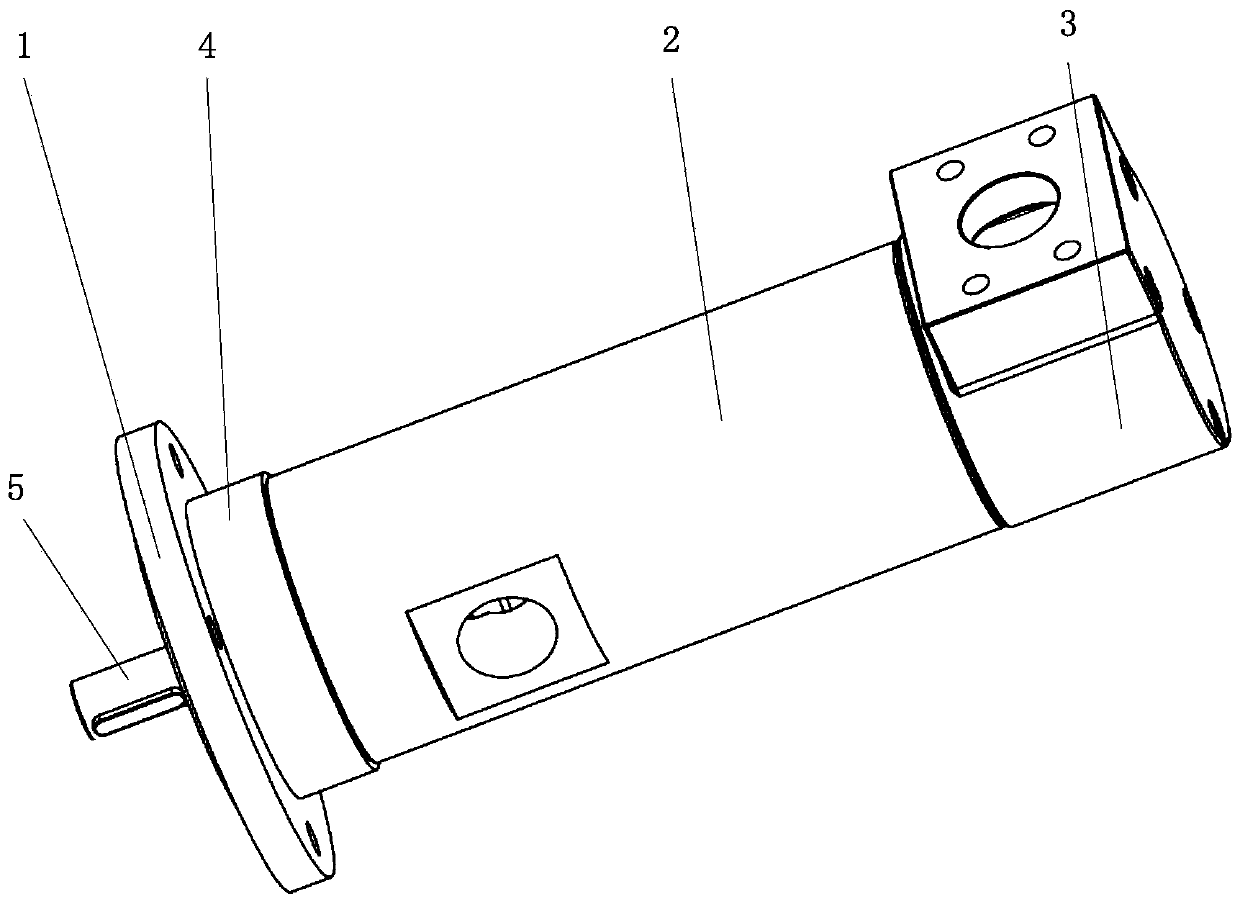

Three-screw labyrinth seal cutting liquid pump

A labyrinth seal and three-screw technology, which is applied to pumps, pump components, rotary piston pumps, etc., can solve the problem of liquid leakage of screw pumps, length limitations of labyrinth seal grooves, and incomplete meshing volumetric efficiency of screw cross-section addendum and dedendum And other problems, to achieve the effect of increased resistance, increased wear resistance, and reduced possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

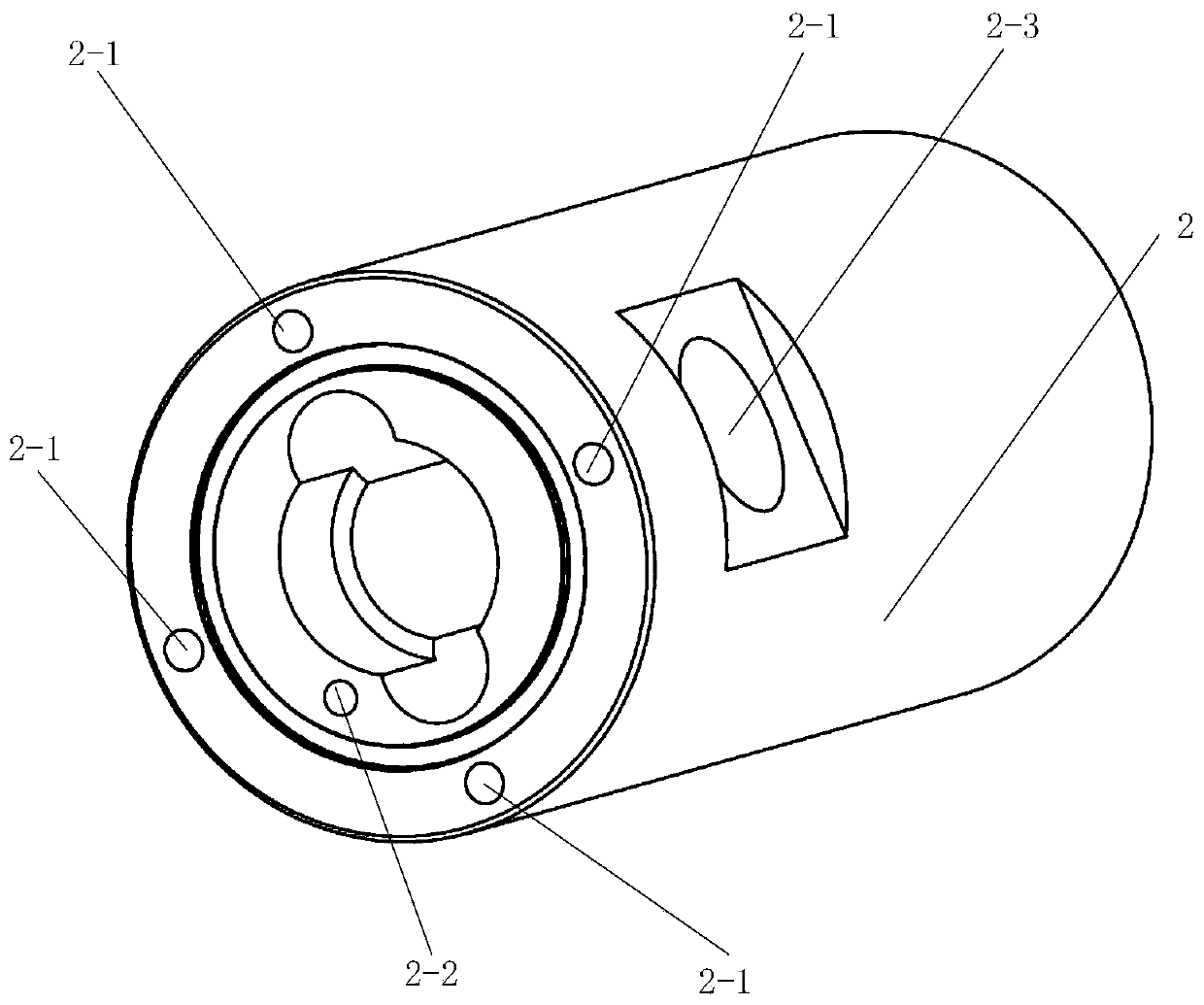

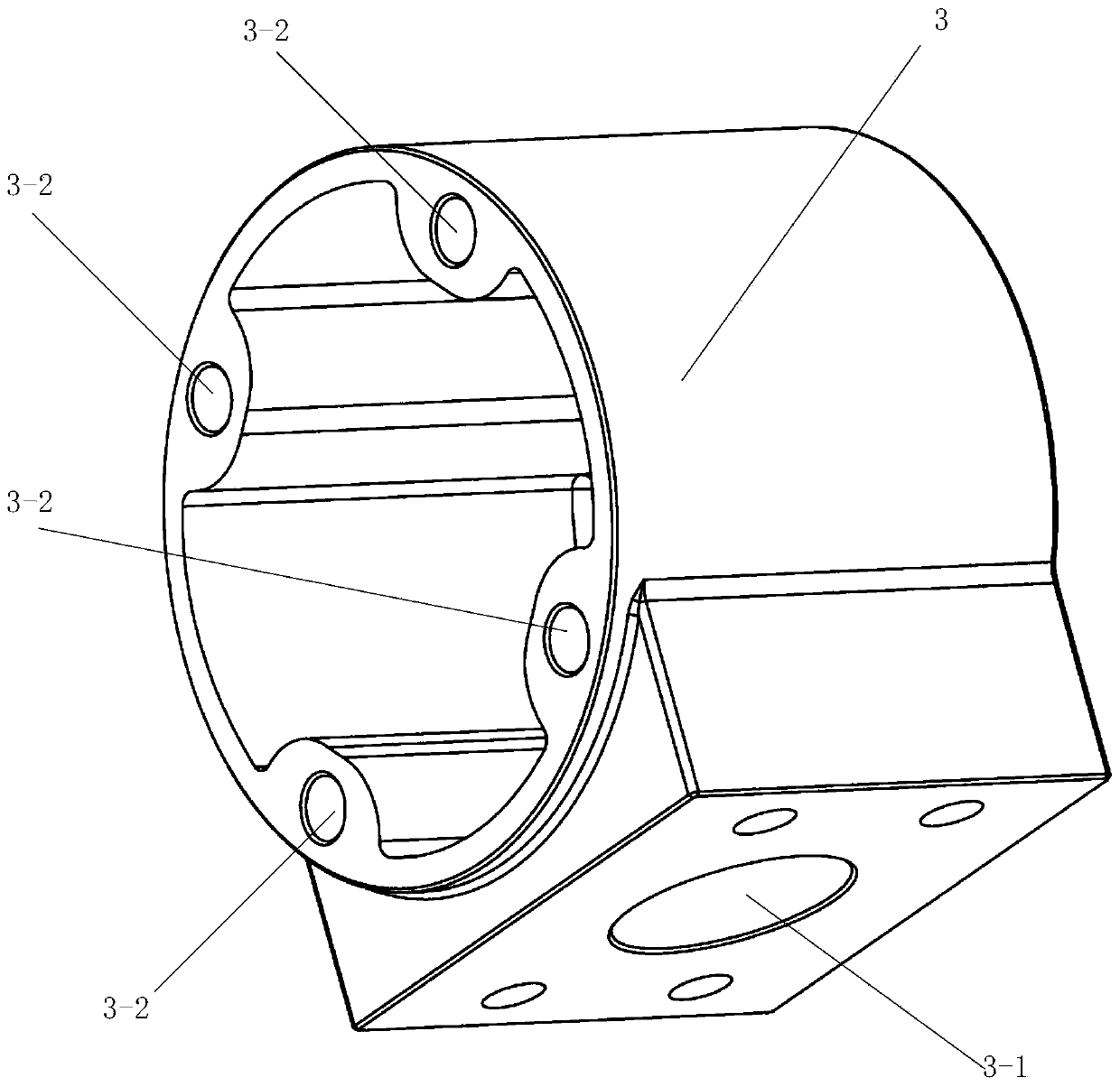

[0032] Design principle of the present invention

[0033]1. Design principle of extended labyrinth seal groove. The traditional labyrinth seal groove is generally arranged in the flange end cover of the pump body, that is, it is arranged at the axial end of the pump body. Due to the limitation of the thickness of the general flange end cover, the length of the traditional labyrinth seal groove is relatively short, which hinders liquid leakage. The distance is relatively short, so the sealing effect is limited. The present invention adds a labyrinth sealing groove flange end cover between the sealing end cover and the housing. The labyrinth sealing groove flange end cover is specially designed to increase the length of the labyrinth sealing groove. The length of the flange end cover is Twice the length of the ordinary flange end cap, including the large outer diameter part and the small outer diameter part, wherein the length of the small outer diameter part is the part longer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com