Construction method of long-span and super-thick tunnel second lining structure

A construction method and large-span technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve problems such as unstable support, high construction risk, and difficult construction, so as to solve construction difficulties, speed up construction schedule, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

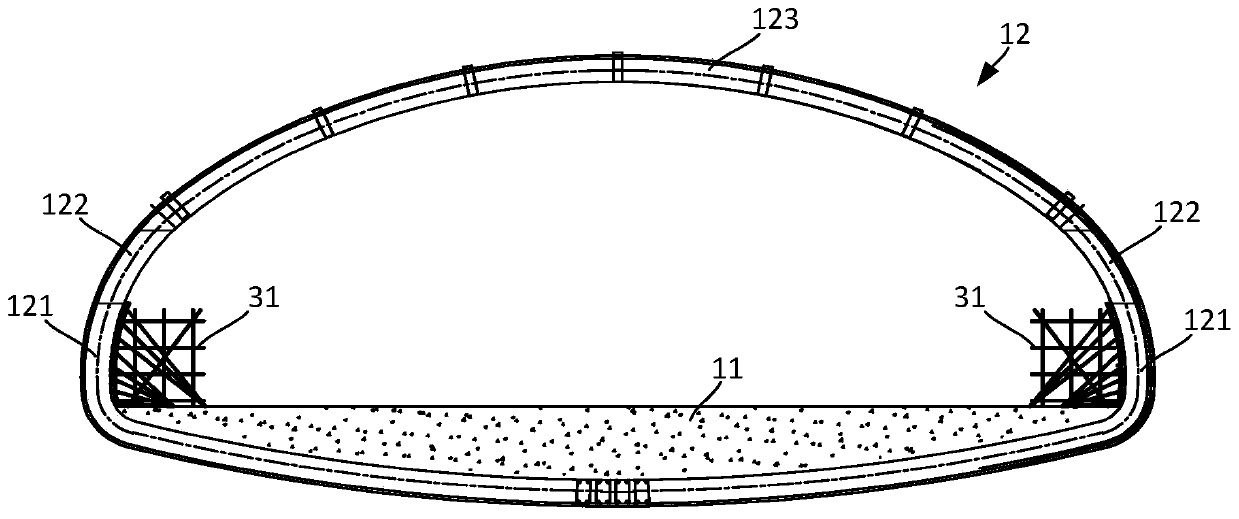

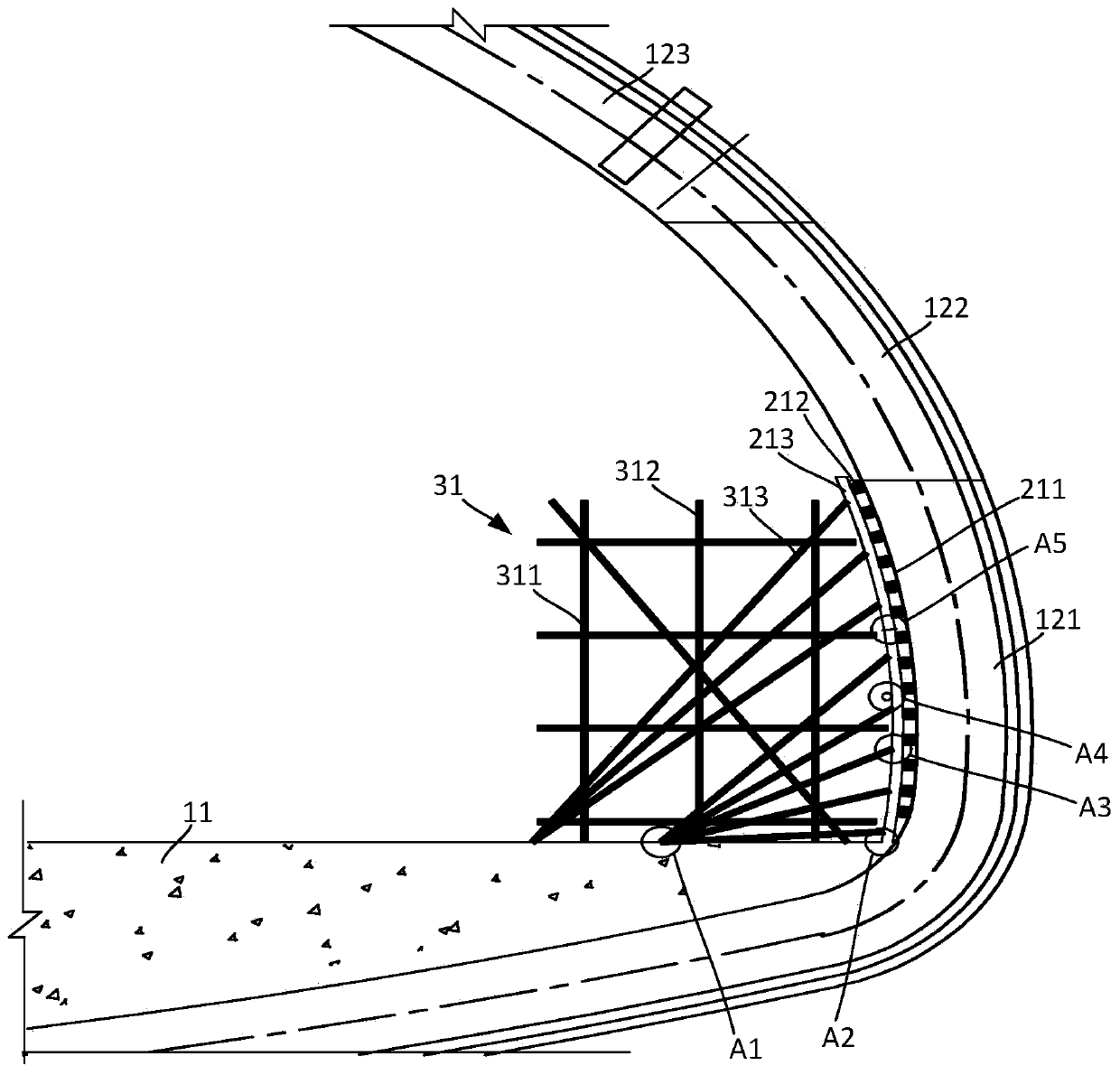

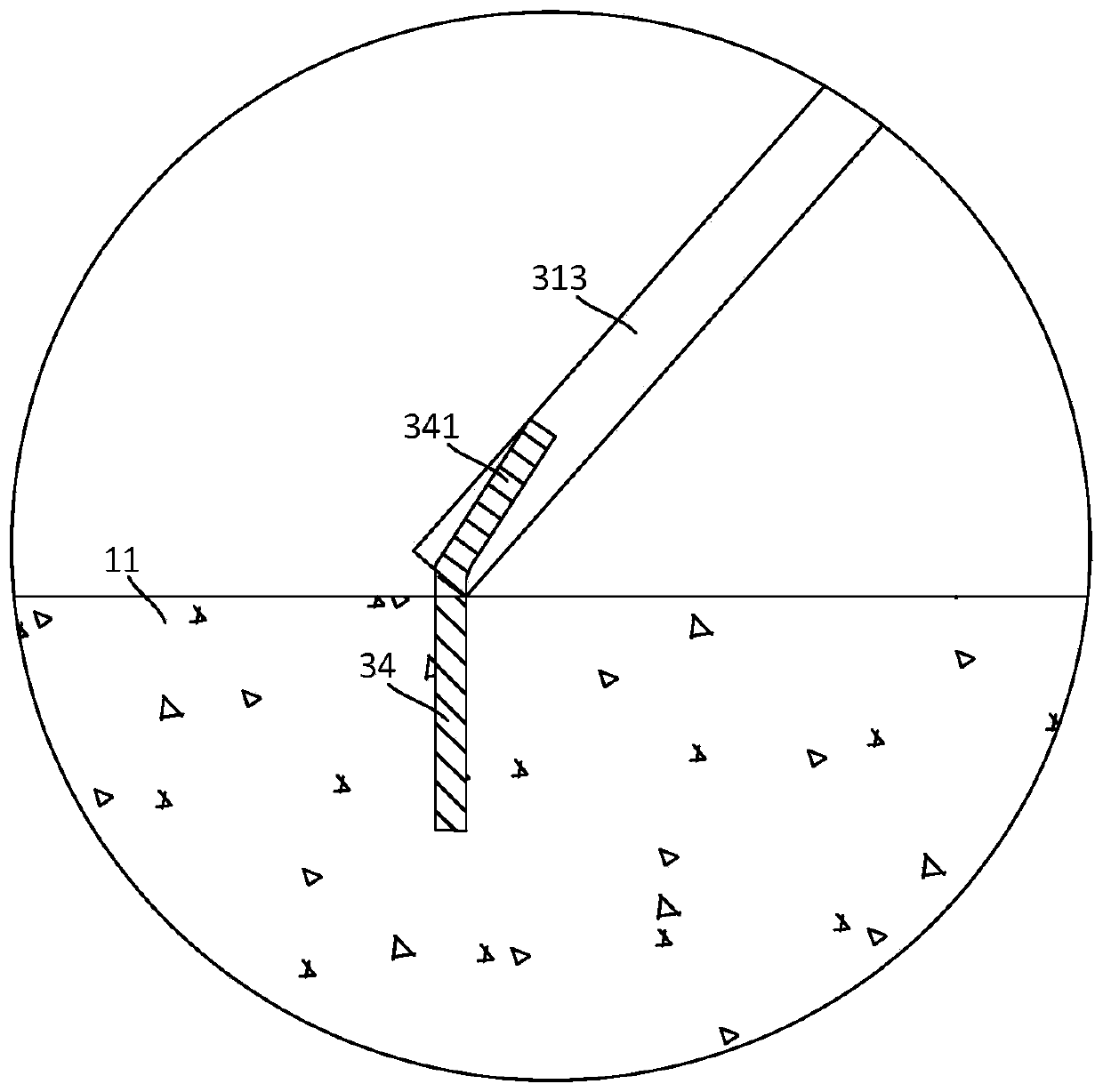

[0061] refer to figure 1 , the present invention provides a construction method for a large-span and ultra-thick tunnel secondary lining structure, which is suitable for the construction of a large cavern secondary lining structure that cannot use trolleys. Thick means that the thickness is greater than or equal to 5m. The main purpose of the invention is to improve the safety in the construction process, ensure construction safety, and solve the difficult problem of large-span ultra-thick secondary lining construction safely and conveniently. The invention overcomes the difficulty and high risk of integral pouring of the second lining in the construction process of the large cavern of the tunnel, and also abandons the bulky large steel pipe support method, strengthens the monitoring and measurement of the frame body process, and solves the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com